Crystalline materials play a crucial role in various industries, ranging from semiconductors to pharmaceuticals. However, identifying the structure of crystalline materials can often be a complex and time-consuming task, especially when dealing with multiphase samples containing different types of crystals. In recent years, machine learning has emerged as a powerful tool for data analysis and pattern recognition. Scientists at Tokyo University of Science (TUS) and other collaborating institutions have developed a new machine learning model that can accurately identify the presence of icosahedral quasicrystal (i-QC) phases in multiphase materials using powder X-ray diffraction patterns. This breakthrough has the potential to revolutionize the field of materials science by expediting the identification of new phases in various crystalline materials.

The identification of unknown phases in multiphase samples has been a longstanding challenge in materials science. Traditionally, scientists relied on their expertise to visually analyze scattered X-rays from powdered samples using powder X-ray diffraction. However, this manual process is time-consuming and prone to human error, particularly when dealing with samples containing multiple phases. To address this challenge, the researchers from TUS developed a machine learning “binary classifier” model.

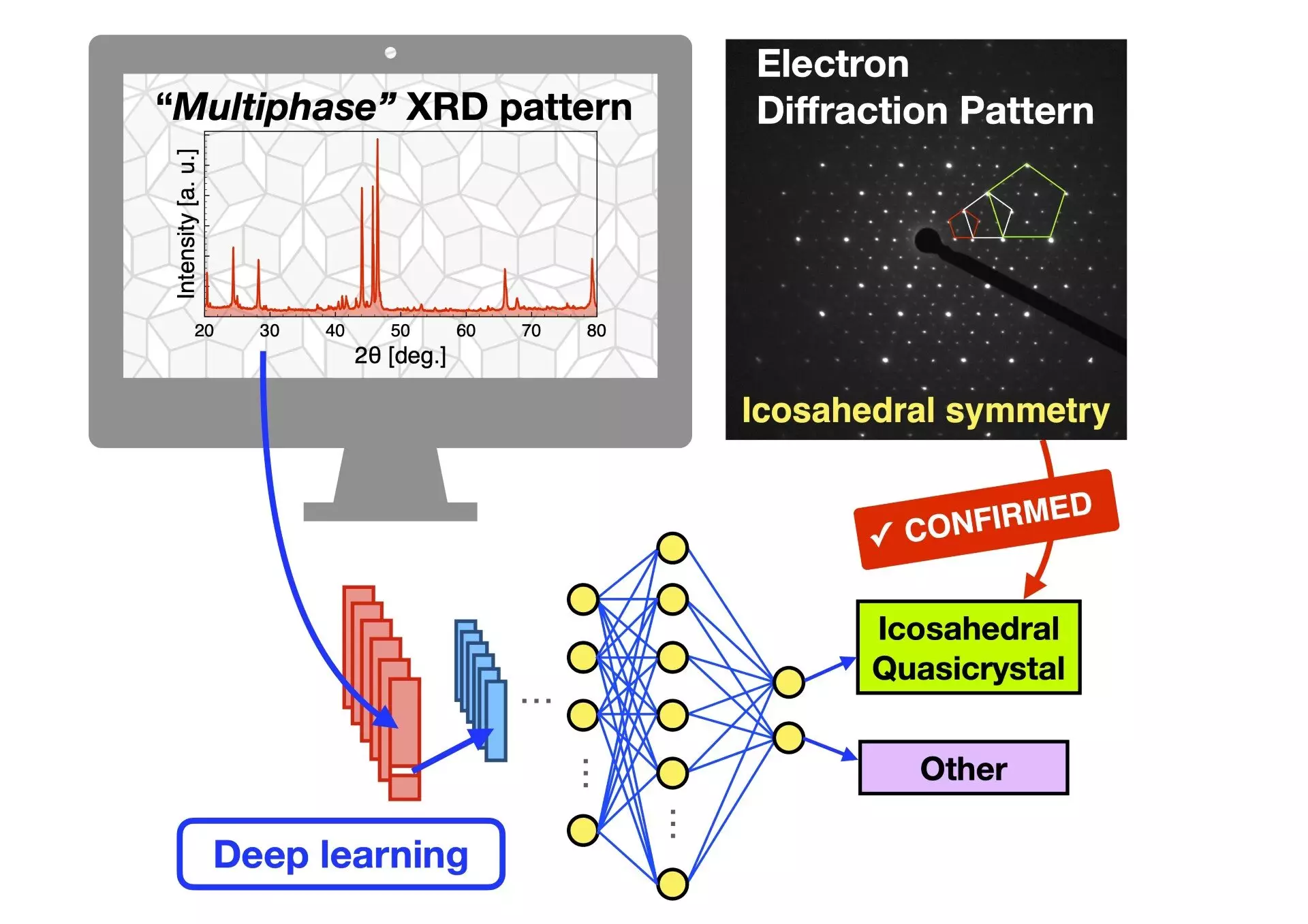

To develop the machine learning model, the researchers created a “binary classifier” using 80 different types of convolutional neural networks. The model was trained using synthetic multiphase X-ray diffraction patterns, which were designed to represent the expected patterns associated with i-QC phases. After the training phase, the model’s performance was evaluated using both synthetic patterns and a database of actual patterns. Remarkably, the model achieved an impressive prediction accuracy of over 92%.

The effectiveness of the machine learning model was further demonstrated by successfully identifying an unknown i-QC phase within multiphase Al–Si–Ru alloys. The model accurately screened 440 measured diffraction patterns from unknown materials in six different alloy systems and identified the presence of the unknown i-QC phase. This identification was later confirmed through the analysis of microstructure and composition using transmission electron microscopy. Notably, the model was able to identify the i-QC phase even when it was not the most prominent component in the mixture, highlighting its versatility and accuracy.

The proposed machine learning model holds great promise in expediting the process of phase identification in multiphase samples. By accurately detecting unknown quasicrystalline phases with high accuracy, scientists can significantly reduce the time and effort required for identifying new phases in various crystalline materials. The model’s application is not limited to i-QC phases; it can also be extended to identify new decagonal and dodecagonal quasicrystals, as well as other types of crystalline materials. This breakthrough has the potential to accelerate advancements in the field of materials science and open up new possibilities for the development of novel materials.

The development of a machine learning model for identifying quasicrystal phases in multiphase materials marks a significant breakthrough in materials science. The model’s ability to accurately detect unknown phases using powder X-ray diffraction patterns demonstrates the power of data-driven methods in overcoming complex challenges. With further advancements in machine learning and data analysis, scientists can expect to make significant strides in the identification of new phases in various crystalline materials. This progress will contribute to the development of next-generation materials for applications in energy storage, carbon capture, electronics, and more.

Leave a Reply