Plastics have undoubtedly revolutionized various industries due to their unique properties. However, their durability has presented a significant challenge when it comes to recycling. The recycling process is hindered by the lack of knowledge about the molecular mechanisms involved in biocatalysis. Fortunately, a recent research project led by a team from Universitat Jaume I has shown promising results in the degradation of widely used PET plastics using a natural enzyme called CALB. By modifying the pH of the medium, the researchers were able to unlock a new pathway for recycling PET, yielding harmless compounds that can be utilized in subsequent synthesis processes.

The team from the Institute of Advanced Materials (INAM) at UJI, led by Vicent Moliner and Katarzyna Świderek, played a critical role in this breakthrough. As computational chemists, their expertise allowed them to make predictions based on theoretical simulations. Their efforts paved the way for the experimental part of the project, carried out by a group from the Center for Cooperative Research in Biomaterials (CIC biomaGUNE) of the Basque Country, led by Fernando López Gallego, and another from the University of the Basque Country, led by Haritz Sardon.

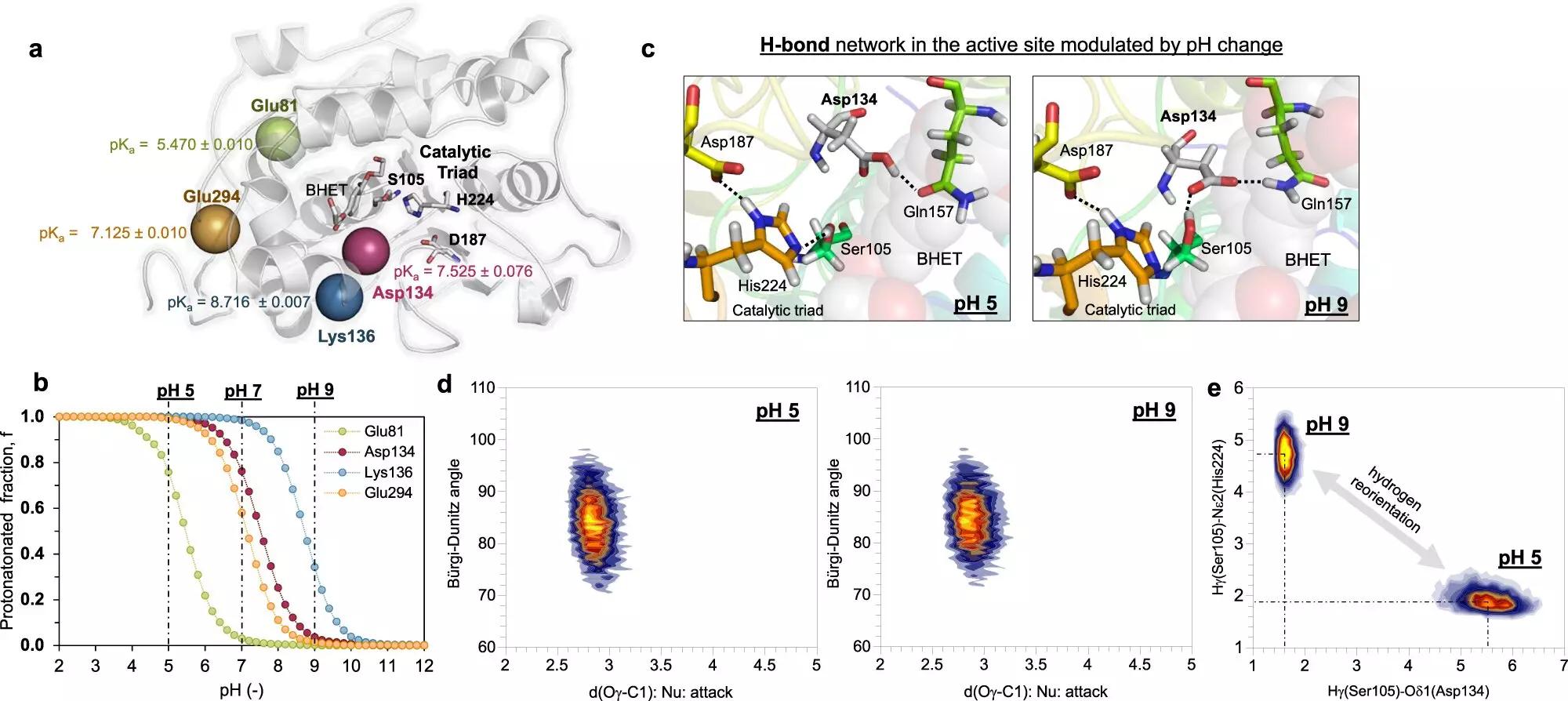

CALB, unlike most enzymes, has the unique capability of catalyzing multiple reactions. This promiscuity became the foundation for the discovery that CALB could effectively degrade PET. The researchers further found that by adjusting the pH of the medium, they could modulate the enzyme’s structure, leading to the production of two types of compounds that are traditionally challenging to obtain. Moreover, this simple mechanism allows for the degradation of synthetic polymers at low temperatures in aqueous solutions while offering control over the end products of the reaction.

While this breakthrough is undoubtedly significant, the researchers are eager to further explore the potential of CALB in recycling plastics. They aim to improve the speed of the reaction by redesigning the enzyme. Additionally, the team at INAM is collaborating with research groups in Sweden and Denmark to explore the degradation of other synthetic polymers such as polyurethanes.

The research conducted by the team from Universitat Jaume I brings us one step closer to efficient and environmentally friendly plastic recycling. By harnessing the power of biocatalysis, the team has demonstrated the potential to overcome the challenge of plastics’ durability. Through the modification of the pH of the medium, the researchers were able to control the reactions and generate valuable compounds for further synthesis processes.

As we strive for a more sustainable future, it is crucial to continue investing in research and development in the field of biocatalysis. The ability to recycle plastics efficiently could reduce our dependence on finite resources and mitigate the harmful impact of plastic pollution on the environment. By understanding the molecular mechanisms involved in biocatalysis, we can unlock the potential of enzymes like CALB and revolutionize the recycling industry.

The recent breakthrough in PET plastic degradation through biocatalysis offers hope and inspiration for a greener future. The collaboration between computational biochemists and experimental researchers has paved the way for further exploration in the field of plastic recycling. By continually delving deeper into the study and making improvements to enzyme design, we can anticipate more efficient and effective methods for recycling not only PET but also other types of synthetic polymers. With the right investments and interdisciplinary collaboration, biocatalysis could become the game-changer we need to tackle the global plastic waste crisis.

Leave a Reply