Metal halide perovskites have emerged as a promising solution for developing photovoltaic technology. With their advantageous optoelectronic properties, recent studies have even demonstrated metal halide perovskite-based solar cells (PSCs) with power conversion efficiencies (PCEs) above 25.8%. This puts them on par with some of the solar technologies available today. However, the existing fabrication processes are far from ideal, limiting their large-scale production and deployment.

The Challenge of Ambient Air Fabrication

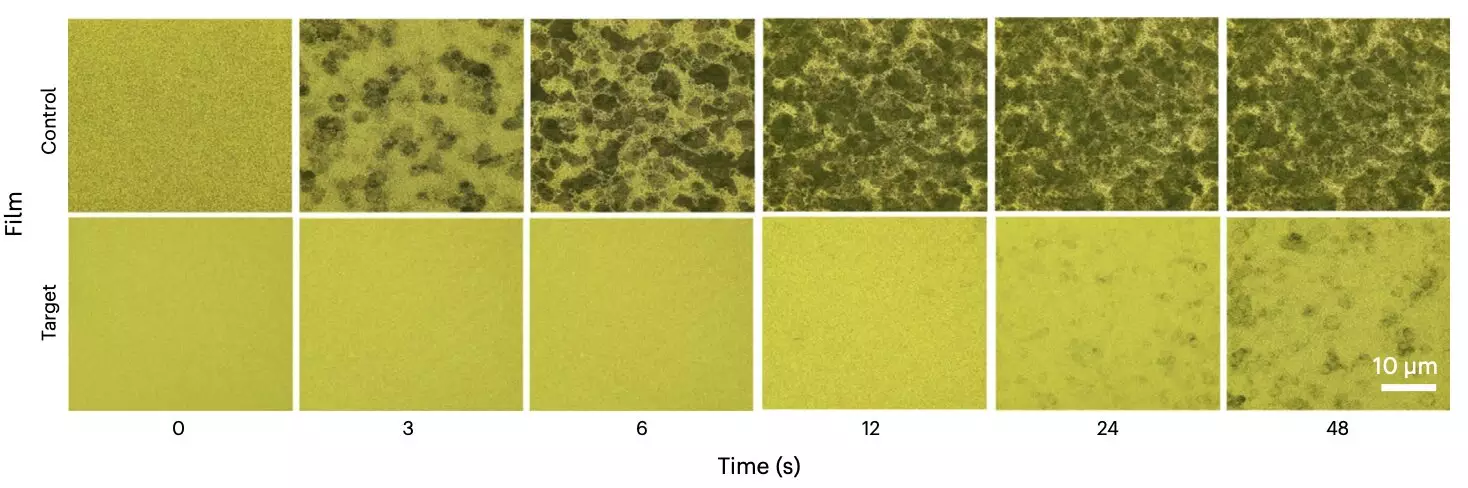

To achieve PCEs above 25%, the fabrication process for metal halide PSCs has required the use of an inert atmosphere, such as a nitrogen glovebox. However, this creates a significant barrier to their large-scale production and increases fabrication costs. Moisture in ambient air triggers severe decomposition of the perovskite layer, leading to material degradation and reducing device efficiency.

A Breakthrough Strategy

Addressing this challenge, researchers at North China Electric Power University have introduced a strategy to fabricate metal halide PSCs with PCEs above 25% in ambient air. By blocking the pathway for perovskite layers to become hydrated, they prevent severe damage to the cells. The researchers achieved this by using the acetate salt form of the chemical compound guanabenz, known as GBA. This compound eliminates cation and anion vacancies, preventing perovskite hydration and enabling the crystallization of a high-quality film in ambient air.

Initial tests of this fabrication strategy have yielded remarkable results. The researchers successfully created stable solar cells based on metal halide perovskites with commercially viable PCEs above 25%. These solar cells also showed great durability, retaining their performance even in humid environments. After 2,000 hours of aging in ambient air and 500 hours of operating at the maximum power point under simulated solar light, the cells maintained around 96% of their initial efficiency. Even under damp heat conditions, the encapsulated devices retained 85% of their initial efficiency after 300 hours.

Towards Low-Cost Fabrication

This groundbreaking work opens up a new avenue for the low-cost fabrication of metal halide PSCs. By enabling the use of ambient air conditions, the researchers have significantly reduced the requirements and costs associated with their production. This could pave the way for the future commercialization of this technology and its widespread adoption.

The strategies and techniques developed by this team of researchers hold immense potential for the future of metal halide perovskite solar cells. By addressing the challenges of moisture-induced degradation, they have overcome a major hurdle in their commercialization. With further advancements and refinements, the performance of these solar cells can be enhanced even further, making them more efficient and reliable.

The ability to fabricate metal halide PSCs with high efficiency in ambient air represents a significant step forward. Not only does it improve the scalability and affordability of this technology, but it also opens up new possibilities for its large-scale production and deployment. The road to commercialization may still have its challenges, but the innovative research and breakthroughs achieved by this team of researchers bring us one step closer to a future powered by metal halide perovskite solar cells.

Leave a Reply