In a recent study conducted by scientists at Tokyo Metropolitan University, a new model has been developed to analyze how amorphous materials respond to stress. By considering groups of atoms and molecules as squishy spheres with different levels of softness, the researchers were able to uncover unexpected patterns in the distribution of forces within the material. This breakthrough has the potential to revolutionize the way we design and understand the behavior of various materials.

Traditionally, the transmission of forces through amorphous solids like concrete has been attributed to the formation of “force chains.” These force chains dictate how stress is distributed within the material and play a crucial role in determining its mechanical properties. However, the exact mechanisms behind the emergence of force chains have remained elusive, leaving researchers with a limited understanding of the behavior of such materials under external loads.

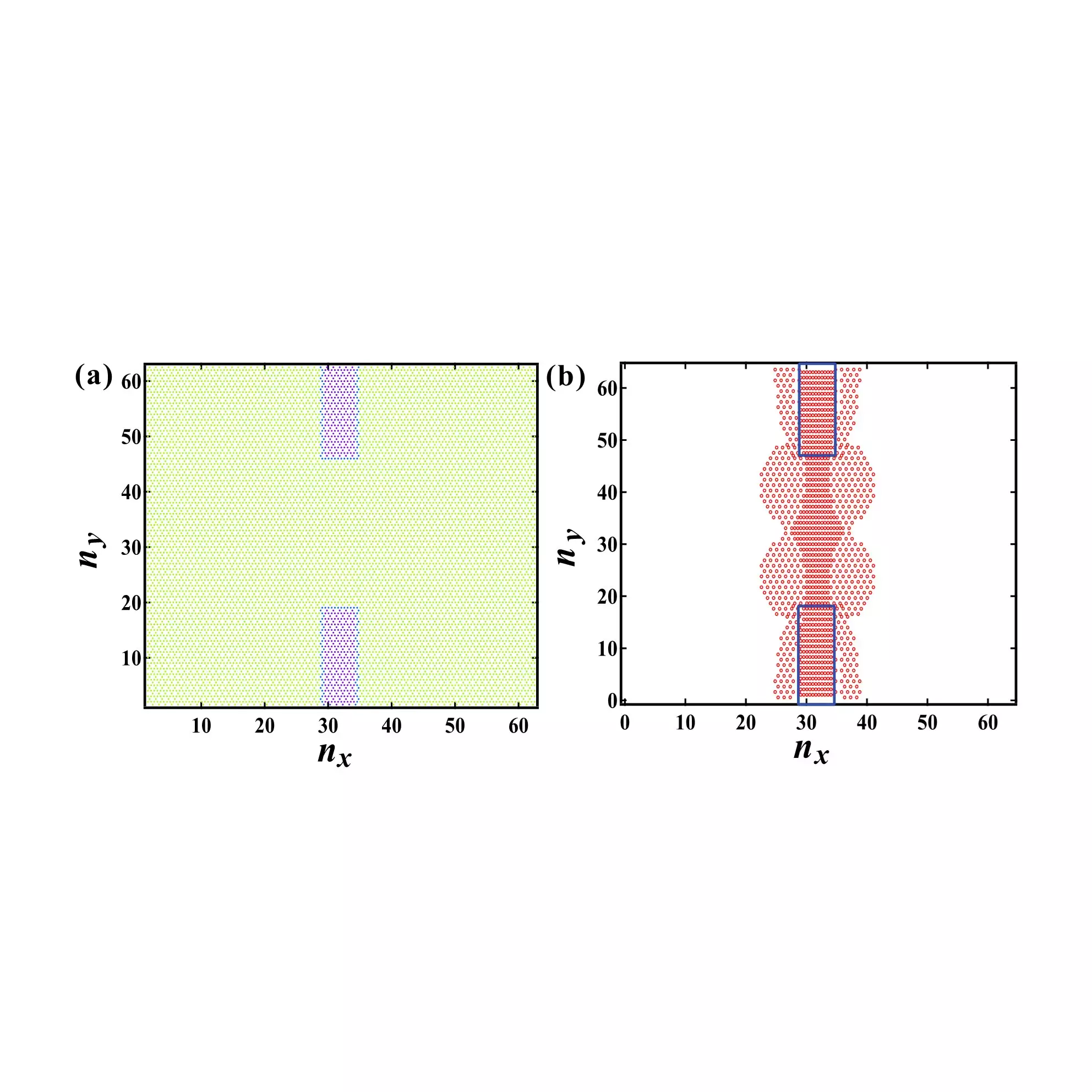

In an attempt to unravel the mystery of force chain formation, Professor Rei Kurita and his team decided to take a different approach. Rather than simulating the motion of individual atoms, they opted to represent groups of atoms as spheres with varying levels of stiffness. This approach allowed them to observe how these groups respond to external forces and how force chains propagate through the material. By deforming their model of squishy particles, the researchers were able to uncover intriguing insights into the nature of force chains.

One of the key findings of the study was the relationship between the softness and stiffness of different regions within the material. While it may seem intuitive to assume that harder regions would give rise to force chains, the researchers discovered that the shape of force chains was more string-like and did not necessarily align with isolated hard regions. In fact, the presence of softer regions between stiff regions actually enhanced the transmission of forces, highlighting the complex interplay between different material properties.

The study also shed light on how variations in softness and the distribution of soft/hard regions impact the overall mechanical properties of the material. It was observed that materials with more uniform stiffness exhibited greater hardness, due to a more even distribution of force chains. This suggests that designing amorphous materials with consistent properties could potentially lead to the development of stronger and more resilient materials.

Future Prospects

While the study provides a significant advancement in our understanding of force chains in amorphous materials, there are still many unanswered questions. The emergence of stiffness variations in real-world materials remains unexplored, leaving room for future research to build upon the current findings. The researchers hope that their novel model will pave the way for new design principles that could revolutionize the way we approach material engineering.

The study conducted by the scientists at Tokyo Metropolitan University offers valuable insights into the mechanics of force chains in amorphous materials. By adopting a unique modeling approach and uncovering the complex interplay between softness, stiffness, and force chains, the researchers have opened new avenues for research and innovation in material science.

Leave a Reply