As the global focus on green hydrogen production continues to grow, the choice of renewable energy sources becomes crucial. Solar energy stands out as a widely available energy source with low dependency on specific geographic locations. However, the variability in solar output due to weather and seasonal changes can present challenges for maintaining the efficiency of green hydrogen production devices. Dr. Bora Seo’s research team at the Korea Institute of Science and Technology (KIST) has developed a groundbreaking durability evaluation technique for green hydrogen production devices utilizing solar energy.

One of the primary challenges in utilizing solar energy for green hydrogen production lies in the fluctuations in solar output. Factors such as weather conditions and seasonal changes can lead to repetitive increases and decreases in power generation. These fluctuations can potentially damage the components of production devices, highlighting the need for precise evaluation techniques to determine the optimal timing for component replacement and material development.

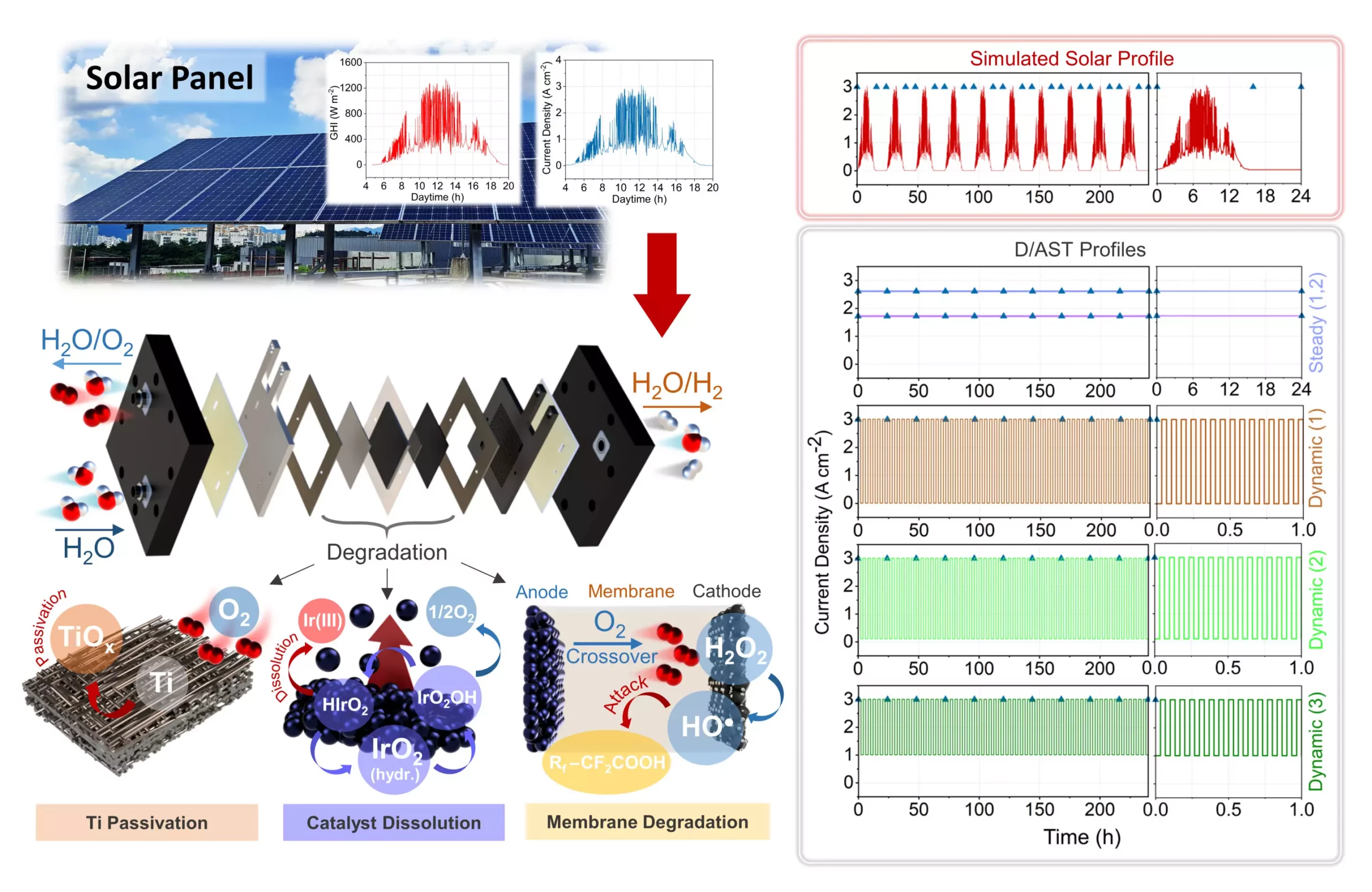

Dr. Bora Seo’s research team at KIST has introduced a revolutionary durability evaluation technique for green hydrogen production devices. By utilizing actual solar irradiance data with step durations as short as one second, the team has achieved the most accurate simulation of fluctuations in solar energy output. This represents a significant advancement compared to existing methods that rely on periodic cycling or constant maintenance of current and voltage. The team’s research, published in the journal Energy & Environmental Science, introduces a new standard for evaluating the durability of core materials for water electrolysis under power fluctuation conditions.

The newly developed simulation method converts irradiance values into current densities using data from solar panels and water electrolysis stacks. By shortening the step duration from 10 seconds to 1 second, the research team can accurately reflect fluctuations in solar output. The team has also proposed key indicators for material development, including catalyst leaching amount, fluoride release rate, and thickness of passivation layer. These indicators offer a standardized analysis method for assessing performance degradation of materials and components, ultimately improving the durability and performance of green hydrogen production devices.

The developed durability evaluation technique not only diagnoses the current condition of solar-based green hydrogen production devices but also predicts their remaining lifespan. This information can streamline equipment investment decisions and enhance the competitiveness of materials and components in the green hydrogen industry. Moreover, this technology is expected to have applications beyond solar energy, extending to other renewable energy sources such as offshore wind and tidal power.

Dr. Bora Seo’s research team’s innovative approach to evaluating solar energy efficiency for green hydrogen production devices sets a new standard for the industry. By addressing the challenges of solar output variability and proposing key indicators for material development, the team has paved the way for more efficient and durable green hydrogen production systems. As the world transitions towards a sustainable energy future, this technology holds promise for revolutionizing the green hydrogen industry.

Leave a Reply