As the world of technology continues to advance at a rapid pace, innovative electronic devices such as foldable displays, wearables, e-skin, and medical devices have emerged. These devices rely heavily on flexible electronic technology, which in turn has created a growing demand for flexible adhesives that can effectively connect various components while maintaining their shape. However, conventional pressure-sensitive adhesives (PSAs) often struggle to strike a balance between recovery capabilities and adhesive strength.

Recently, researchers at UNIST conducted an extraordinary study to address this critical challenge. Led by Professor Dong Woog Lee from the School of Energy and Chemical Engineering, the research team successfully synthesized new types of urethane-based crosslinkers that revolutionize the field of flexible adhesives. By incorporating novel materials into pressure-sensitive adhesives, they achieved significantly improved recoverability compared to traditional methods.

The key to this breakthrough lies in the utilization of m-xylylene diisocyanate (XDI) or 1,3-bis(isocyanatomethyl)cyclohexane (H6XDI) as hard segments, along with poly(ethylene glycol) (PEG) groups serving as soft segments. These crosslinkers provide the necessary structure and properties to enhance the recovery capabilities of the adhesive.

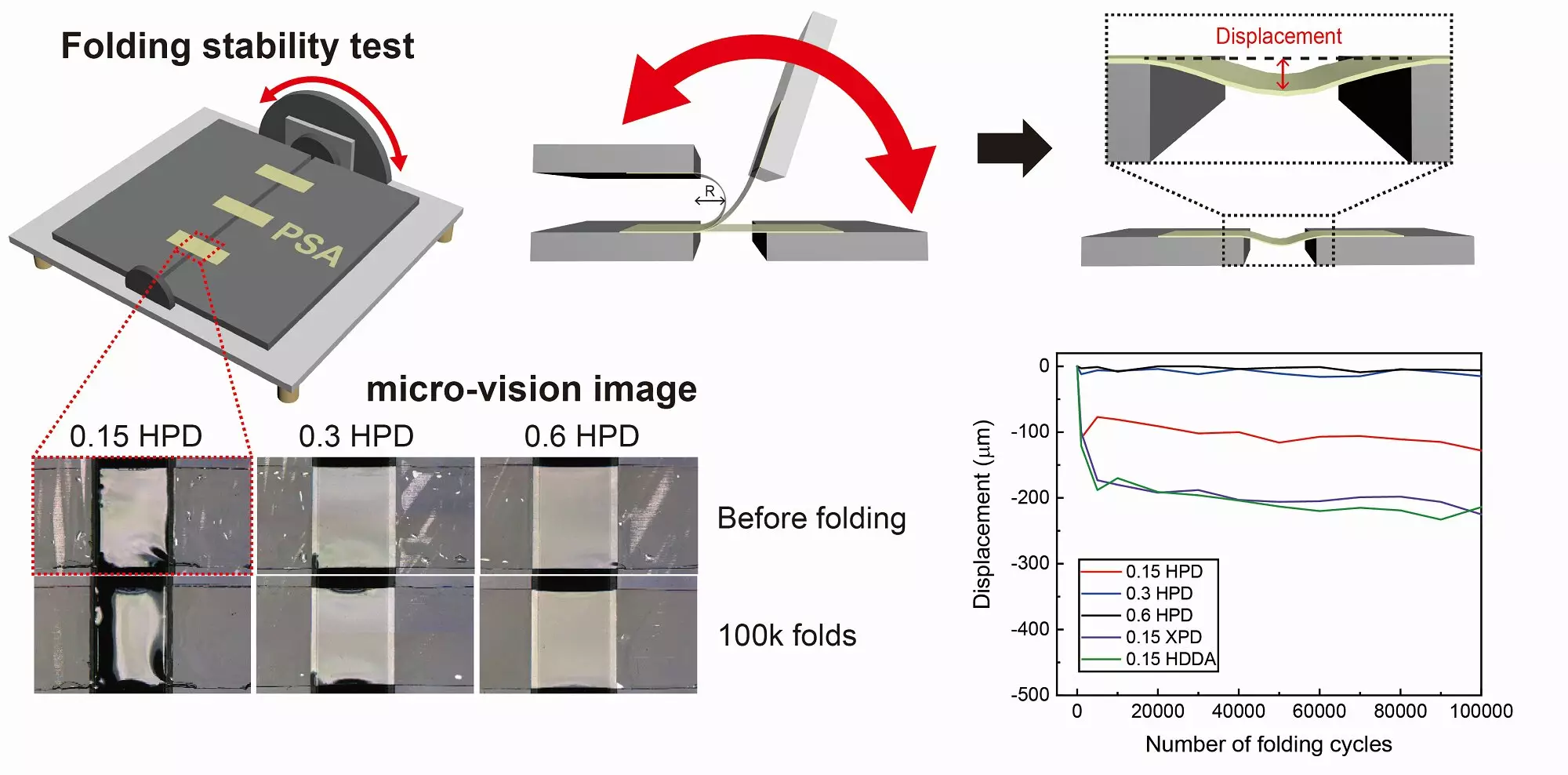

One particular formulation, known as H6XDI-PEG diacrylate (HPD), demonstrated exceptional recovery properties while maintaining high adhesion strength (~25.5 N 25 mm−1). Through extensive testing involving folding and stretching totaling tens of thousands of cycles, the PSA crosslinked with HPD showcased remarkable stability under repeated deformation. This highlights its potential for applications requiring both flexibility and recoverability.

In addition to its impressive recovery capabilities, the adhesive also displayed high optical transmittance (>90%) even after subjecting it to strains up to 20%. This characteristic makes it particularly suitable for fields such as foldable displays that demand not only flexibility but also optical clarity. The ability of the adhesive to maintain its transparency opens up new possibilities for the development of electronic products with both high flexibility and rapid recovery characteristics.

Professor Lee expressed his excitement for the future of this adhesive technology, stating that it offers promising possibilities for electronic products that require both high flexibility and rapid recovery characteristics. The breakthrough in balancing adhesion strength and resilience opens up new avenues for the development of flexible electronic devices, paving the way for further advancements in the field.

Hyunok Park, a researcher involved in the study, underlined the significance of this research. The introduction of this new crosslinking structure has led to an adhesive with exceptional adhesion and recovery properties. This breakthrough not only addresses the long-standing challenges in adhesive technology but also unlocks the potential for a wide range of electronic applications.

The future of flexible adhesives looks promising with the advancements made in this extraordinary study conducted at UNIST. The development of urethane-based crosslinkers has revolutionized the field, enabling flexible adhesives to achieve a balance between recovery capabilities and adhesive strength. With applications in foldable displays, wearables, e-skin, and medical devices, this breakthrough adhesive technology opens up new possibilities for the development of electronic devices that require both flexibility and rapid recovery characteristics. As technology continues to evolve, these advancements will contribute to the creation of more innovative and versatile electronic products.

Leave a Reply