The building envelope plays a critical role in protecting occupants from external environmental factors such as sun, rain, snow, wind, and pollution. This multilayer component not only contributes to the energy efficiency of a building but also ensures the health and comfort of its residents. However, issues such as air leakage, heat transfer, and moisture diffusion can significantly impact the performance of the building envelope, leading to the growth of mold, degradation of materials, and decreased insulation effectiveness. In light of these challenges, researchers are constantly exploring innovative materials and solutions to enhance the functionality and durability of building envelopes.

Within the building industry, various barrier membranes, including plastic sheeting and rigid foam insulation, are commonly used to construct building envelopes. While polyethylene extruded sheets are widely employed as vapor barrier membranes, their excessive use poses environmental concerns. As a result, materials scientists are turning to biopolymers like polyhydroxyalkanoate (PHA) and polylactic acid (PLA) as sustainable alternatives. Recent advancements have also introduced the use of cellulose-based fillers as reinforcements in polymer composites. Capitalizing on these developments, Masoud Dadras Chomachayi and his research team at Laval University in Canada have developed a groundbreaking sandwich-structured composite for building envelopes.

A Groundbreaking Composite Solution

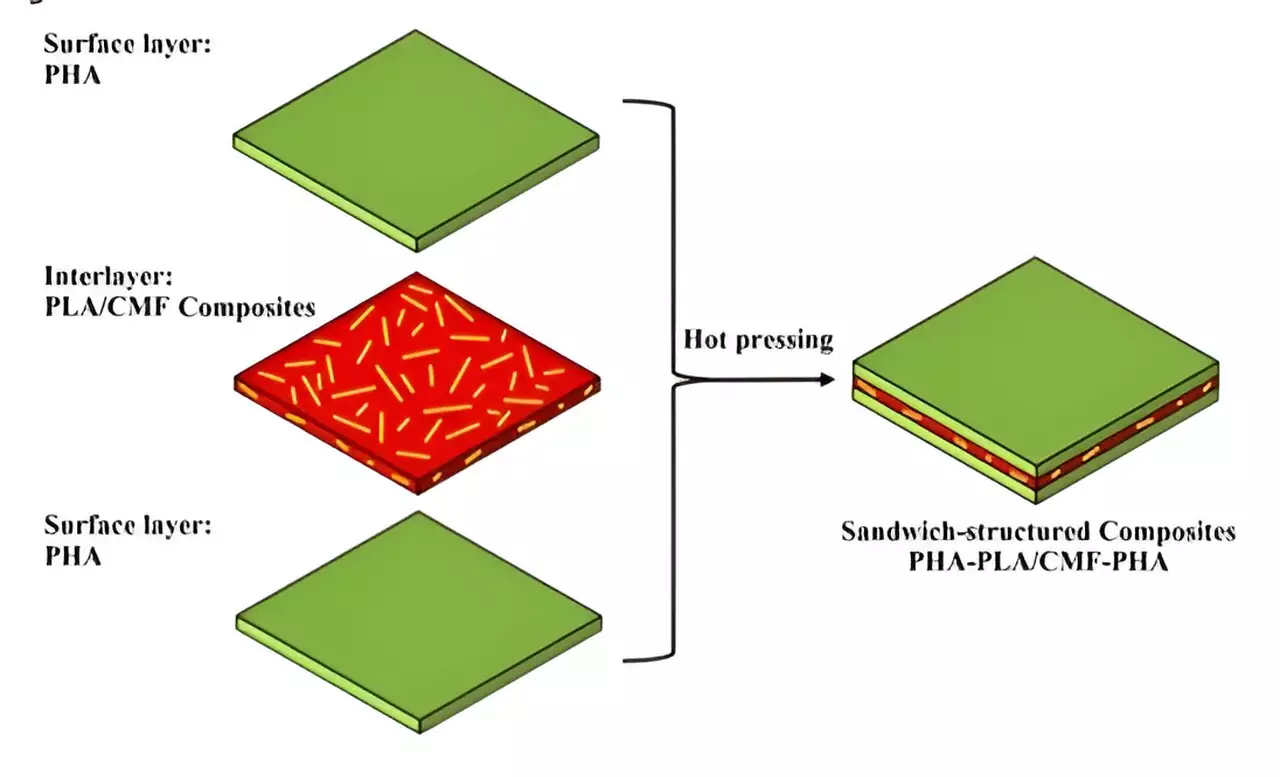

Chomachayi and his team have successfully created a sandwich-structured composite by combining the surface layers of PHA, an excellent vapor barrier material, with an interlayer of PLA and cellulose microfibers. To improve the compatibility between natural reinforcements and the polymer matrix, the cellulose microfibers undergo a sol-gel process for chemical modification. This process imparts highly hydrophobic characteristics to the modified cellulose microfibers, ensuring their homogenous dispersion within the PLA matrix. The resulting composite exhibits enhanced thermal stability, mechanical properties, and water vapor permeability compared to composites containing untreated cellulose microfibers.

The research team conducted an extensive characterization of the prepared sandwich composites, evaluating their morphology, thermal stability, mechanical properties, and vapor barrier performance. Scanning electron microscopy was used to examine the surface morphology of the cellulose microfibers before and after modification. The addition of silica nanoparticles during the sol-gel modification process imparted roughness to the cellulose fibers. Fourier transform infrared analysis provided insights into the chemical structure of the modified cellulose microfibers.

One of the key findings of the research was the significant improvement in the hydrophobicity and thermal stability of the cellulose microfibers after the sol-gel modification process. Contact angle measurements demonstrated that the modified microfibers exhibited higher contact angle values compared to the untreated surfaces, indicating enhanced hydrophobic properties. This modification process also contributed to increased durability and long-term stability of the composite materials.

The successful development of the sandwich-structured composite signifies the potential of biopolymers as sustainable alternatives to conventional, petroleum-based materials in construction applications. By incorporating PHA sheets and PLA composites reinforced with modified cellulose microfibers encrusted with spherical silica nanoparticles, the research team achieved improved Young’s modulus, enhancing the mechanical properties of the composite. These advancements pave the way for future studies aimed at further enhancing the flexibility and applicability of these composites in diverse construction scenarios.

As the concept of material durability gains significant attention, this groundbreaking research provides a promising solution for the long-term use of vapor barrier membranes in building envelopes. By regulating the migration of water vapor through the walls, the developed composite effectively prevents moisture accumulation and ensures the longevity of the building materials. The use of biopolymers not only addresses environmental concerns but also aligns with the global shift towards sustainable construction practices.

The innovative composite developed by Chomachayi and his research team opens new avenues for the evolution of building envelopes. By leveraging the unique properties of biopolymers like PHA and PLA, as well as the modified cellulose microfibers, this sandwich-structured composite offers enhanced performance, durability, and sustainability. With continued research and development, these composites have the potential to revolutionize the construction industry and contribute to a greener, more sustainable future.

Leave a Reply