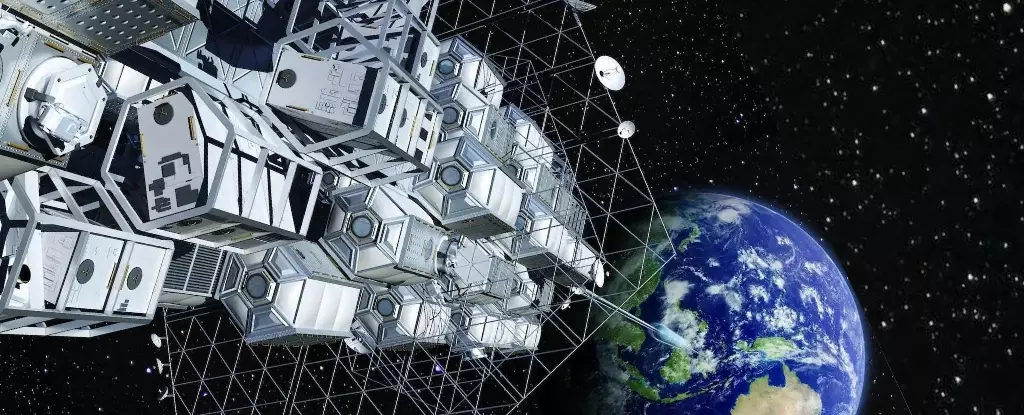

The concept of a space elevator has long captured the imagination of scientists and engineers, promising to revolutionize space travel by significantly reducing costs and travel times. One of the main advantages of a space elevator is its potential to transport cargo and humans to orbit without the need for expensive rockets or fuel. Instead, electromagnetic vehicles called climbers could shuttle cargo to space, powered remotely through solar power or microwaves. According to Yoji Ishikawa’s report for the Obayashi Corporation, this innovative approach could drastically reduce the cost of transporting goods to space to $57 per pound, significantly lower than current rocket launch prices.

In addition to cost savings, a space elevator offers other benefits such as enhanced safety and sustainability. With no rockets involved, there is no risk of explosions, making space travel safer. Furthermore, climbers could be designed as zero-emission vehicles, reducing the environmental impact of space travel. The slower speed of the climbers, traveling at 124 miles per hour, would also result in fewer vibrations than traditional rockets, which is beneficial for delicate equipment.

Despite the potential benefits of a space elevator, there are significant challenges that must be overcome before such a structure can become a reality. One of the main obstacles is determining the material to use for the tether or tube that would connect Earth to space. Traditional materials like steel would require an impractical amount of material due to the extreme tension the structure would be under. As Johnson pointed out, building a space elevator out of steel would require more steel than currently exists on Earth.

To address this challenge, Ishikawa suggested the use of carbon nanotubes as a potential material for the space elevator. Carbon nanotubes are incredibly strong and lightweight, making them ideal for this application. However, there is a limitation in the length of nanotubes that have been produced so far, with the longest being only about 2 feet. To reach geosynchronous orbit, the tether would need to be at least 22,000 miles long, posing a significant obstacle that researchers have yet to overcome.

In addition to material challenges, there are technical and environmental hurdles that must be addressed in the construction of a space elevator. The extreme tension on the tether makes it susceptible to snapping, and factors like lightning strikes and severe weather conditions like tornadoes, monsoons, and hurricanes could pose a threat to the structure. Locating the tether base at the equator and in the open ocean could mitigate some of these risks, but challenges still remain.

Furthermore, the sheer scale of the project presents a significant financial obstacle. Raising funds for the construction of a space elevator would be crucial, as estimated costs for the project range in the billions of dollars. The need for partnerships and collaboration across industries is essential to tackle the multifaceted challenges associated with building a space elevator.

Building a space elevator presents a host of challenges, ranging from material limitations to technical and environmental obstacles. While the potential benefits of such a structure are compelling, overcoming these hurdles will require significant innovation, collaboration, and investment. While the timeline for the construction of a space elevator remains uncertain, continued research and development in this area could pave the way for a new era of space travel and exploration.

Leave a Reply