The field of adhesives is incredibly diverse, with applications ranging from everyday uses like paper and fabric to specialized needs such as woodwork. However, in the medical arena, adhesives play a crucial role in suturing internal wounds, attaching sensors, and implanting medical devices. Excitingly, a recent breakthrough in this field has opened up new possibilities – the development of medical adhesives that are not only safe for human use but also customizable for specific organs.

Professor Hyung Joon Cha from Pohang University of Science and Technology (POSTECH), along with a team of researchers, has gained attention for their development of customized underwater bio-adhesive patches (CUBAP). Their research, published in the journal Advanced Materials, utilizes mussel-derived adhesive proteins to create these unique patches. These patches are specifically designed to effectively seal internal wounds, leaks, and perforations in the body’s organs, aiding in healing and tissue regeneration.

As the field of internal transplant devices continues to advance, there is an increasing need for adhesives that can securely hold these devices in place. The adhesives used in such applications must maintain strong adhesion underwater while minimizing any potential side effects. Additionally, the ability to customize features like biodegradation time is crucial, taking into consideration the unique biological environments of different organs.

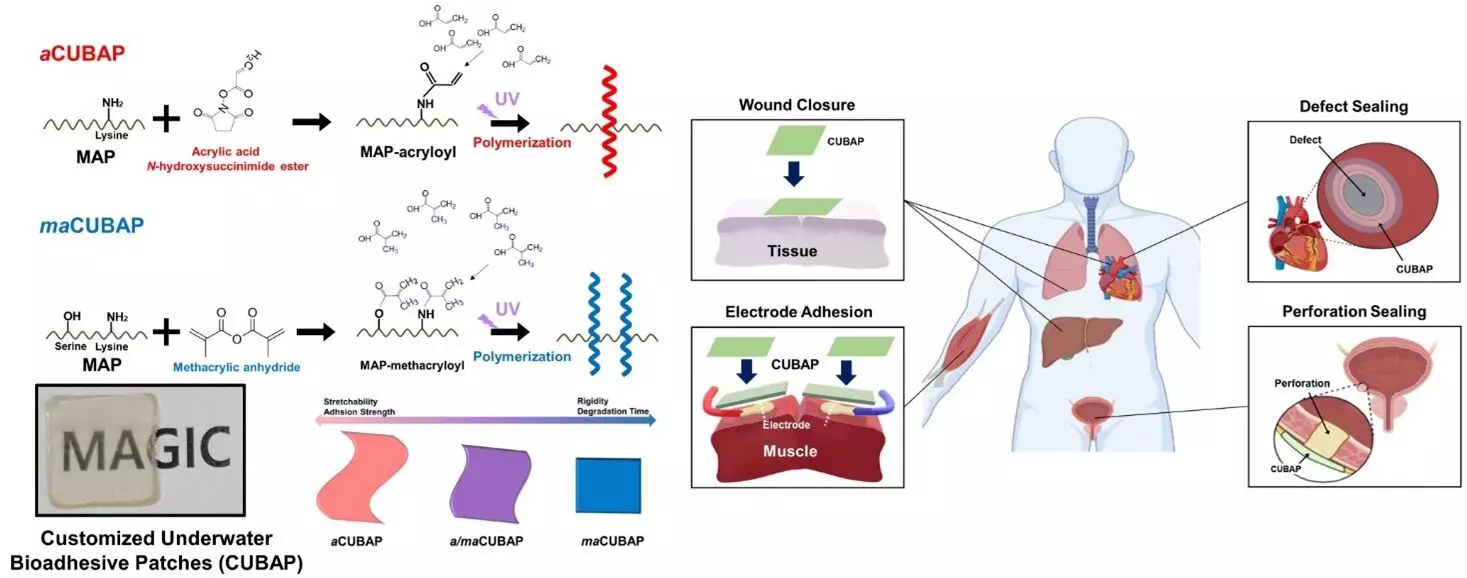

Professor Hyung Joon Cha’s research team, pioneers in utilizing mussel adhesive proteins for medical adhesives, has taken a significant step forward with the development of CUBAP. This adhesive not only demonstrates excellent underwater adhesion but is also composed of natural materials, ensuring safety and biocompatibility within the human body. By combining mussel adhesive protein with polyacrylic acid and polymethacrylic acid, the team has produced customized patches that are currently undergoing clinical evaluation for minimizing scarring in skin closures.

The adhesive patches created by Professor Cha’s team are non-adhesive in their dry state. However, when exposed to the human body or other humid environments, they exhibit strong adhesive properties. By adjusting the ratios of polyacrylic acid and polymethacrylic acid, the researchers can control the degradation time and mechanical hardness of the patches. This adaptability allows for a customized adhesive system, tailored to the specific structural and biological needs of each organ.

In animal treatments and implants, the research team applied three types of customized adhesive patches with promising outcomes. These patches maintained high adhesion even in highly mobile organs, such as the heart and bladder. Additionally, successful experiments were conducted to adjust biodegradation times and flexibility during the transplantation of muscle regeneration electronic devices.

Professor Cha emphasized the significance of this research, stating that it paves the way for personalized medical applications. The team plans to enhance and refine the process through subsequent studies, aiming for effective applications in diverse biomedical fields. Senior Researcher Hwa Hui Shin from K-MEDI Hub also highlights the effectiveness and versatility of the developed bio-adhesive patches.

The development of customizable medical adhesives for internal wounds and transplants represents a significant advancement in the field. By utilizing mussel-derived adhesive proteins, researchers have created adhesive patches that not only exhibit strong underwater adhesion but are also safe and biocompatible within the human body. With the ability to customize features like degradation time and hardness, these adhesive patches hold immense promise for personalized healthcare applications. As further research is conducted and the process refined, the future of medical adhesives looks increasingly bright.

Leave a Reply