Dispersions of polymer particles in a liquid phase, known as latexes, have diverse applications in various fields such as coatings technology, medical imaging, and cell biology. A recent breakthrough by a team of French researchers has led to the development of a method for producing stable polystyrene dispersions with unprecedentedly large and uniform particle sizes. This groundbreaking approach has the potential to revolutionize the field of latex production and unlock numerous new possibilities in advanced technologies.

Narrow size distributions are crucial in many cutting-edge technologies, but achieving them has always been a challenge when it comes to photochemical processes. Polystyrene, a commonly used material for creating expanded foam, is well-suited for producing latexes. These latexes consist of microscopically tiny polystyrene particles suspended in a solution, which are utilized in the production of coatings, paints, and various scientific research applications such as microscopy, medical imaging, and cell biology studies. Traditionally, latexes are produced through thermal or redox-induced polymerization within the solution. However, the lack of external control over these processes limits their efficiency and precision.

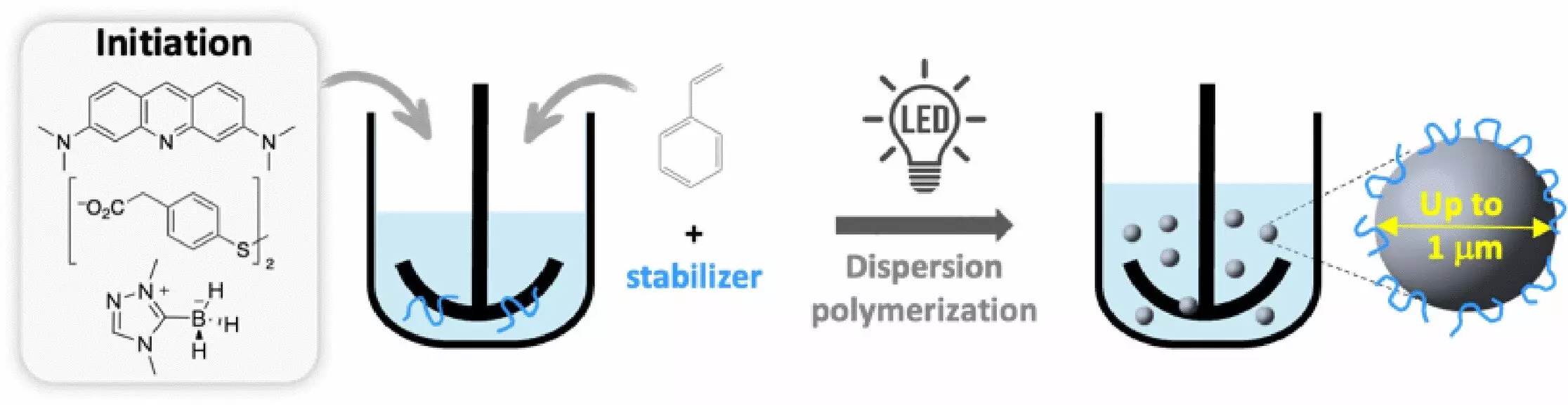

To overcome the limitations of traditional methods, the French research team led by Muriel Lansalot, Emmanuel Lacôte, and Elodie Bourgeat-Lami from the University of Lyon 1 turned to light-driven processes. Unlike thermal methods, light-driven polymerization offers temporal control, allowing the polymerization process to proceed only in the presence of light. The researchers developed a fine-tuned chemical initiation system that responds to standard LED light in the visible range, thus eliminating the need for hazardous UV light. This innovative polymerization system, based on an acridine dye, stabilizers, and a borane compound, became the first to break the “300-nanometer ceiling,” which was the size limit of UV and blue-light-driven polymerization in a dispersed medium.

The breakthrough in light-driven polymerization allowed the research team to produce polystyrene latexes with particle sizes greater than one micrometer and highly uniform diameters. This is a remarkable achievement, as it opens up exciting possibilities for various applications beyond polystyrene. The team envisions the system being utilized in areas such as films, coatings, supports for diagnostics, and more. Furthermore, the polymer particles can be modified with additional functionalities like fluorescent dyes or magnetic clusters, making them even more valuable for diagnostic and imaging applications.

The development of this revolutionary method for producing stable polystyrene latexes has immense potential in various fields of science and technology. By overcoming the limitations of traditional thermal methods, the research team has paved the way for advanced applications, improved precision, and enhanced control in latex production. This breakthrough serves as a testament to the power of innovation and highlights the importance of pushing the boundaries of scientific knowledge to unlock new possibilities. As this method continues to evolve and be refined, it has the potential to revolutionize the field and lead to further advancements in coatings technology, medical imaging, and cell biology research. The future of latex production is now brighter than ever before.

Leave a Reply