The techniques of work hardening, rooted in ancient practices of blacksmithing during the Bronze and Iron Ages, underscore a pivotal evolution in metallurgy. Early metallurgists intuitively discovered that by deforming metal through methods like hammering and bending, they could enhance its strength. This phenomenon, now recognized as work or strain hardening, has significant implications in contemporary manufacturing, playing a crucial role in the resilience of structures from vehicle frames to overhead transmission wires. Reflecting on the past not only provides insights into historical craftsmanship but also sets the stage for modern advancements in material science.

In a groundbreaking study from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), researchers have finally succeeded in observing the intricacies of work hardening in real time—a feat unattainable until now. Conducted at the Harvard Materials Research Science and Engineering Center (MRSEC), this research dispels long-standing uncertainties about the mechanics dictating how metals and other materials grow stronger when subjected to stress. By publishing their findings in the renowned journal *Nature*, the research team has opened new avenues for material design and manufacturing processes.

Frans Spaepen, the John C. and Helen F. Franklin Professor of Applied Physics at SEAS, highlights the significance of this research. “Understanding the underlying laws that govern work hardening is essential for refining our large-scale computational models,” he explains. This study offers insights that could vastly improve these models, making them more effective and applicable in industrial settings.

Historically, observing the process of work hardening in metals has proven challenging, largely due to the limitations of electron microscopy, which only allows for before-and-after comparisons of atomic structures but lacks real-time insight. Researchers previously identified that the formation of dislocations—the tiny imperfections in the structure of metals—creates a complex network of defects that contribute to work hardening. However, the precise interactions among these defects remained elusive.

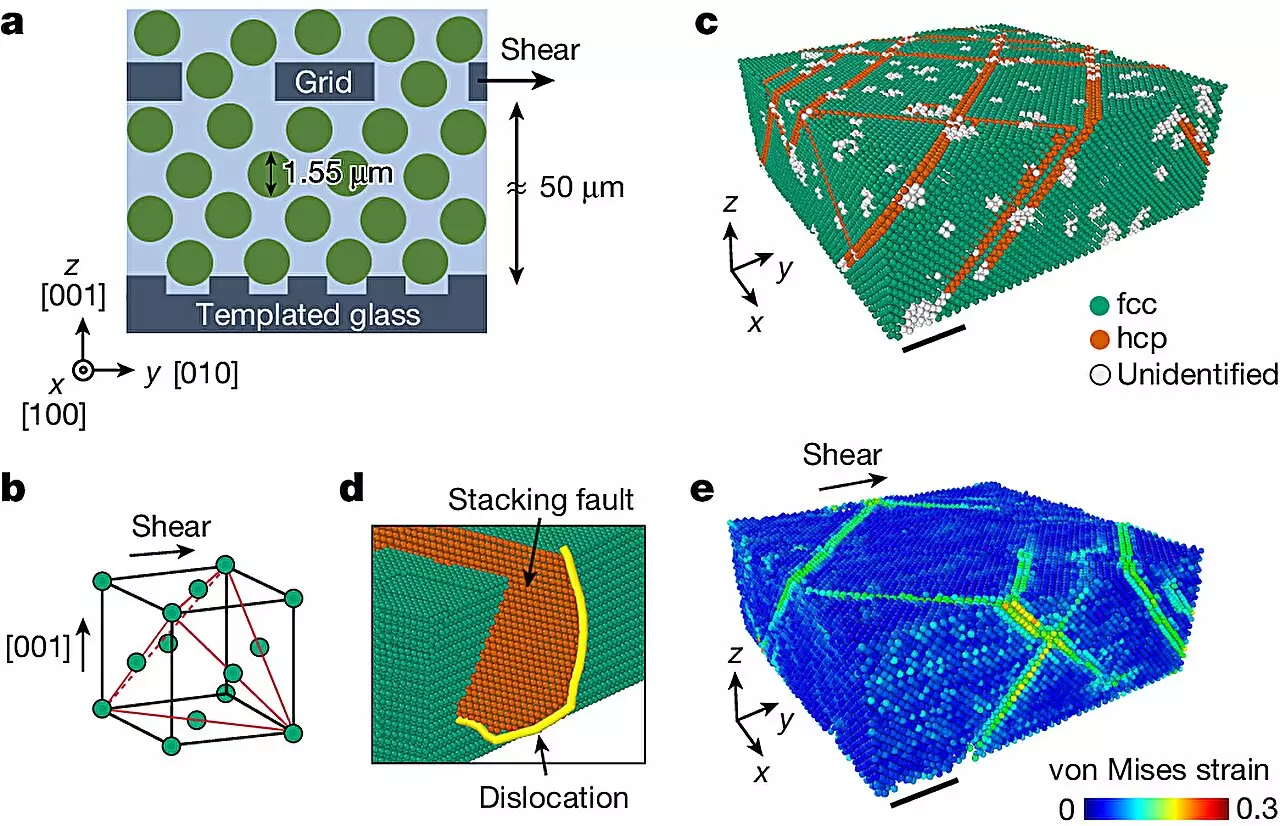

To bridge this gap, the Harvard team utilized colloidal crystals, which consist of particles significantly larger than individual atoms but can still mimic the key characteristics of atomic systems. These crystals form spontaneously under high concentrations, enabling an easier study of their structural dynamics. Remarkably, colloidal crystals are approximately 10,000 times larger than their atomic counterparts, thus providing a more accessible platform for real-time observation through confocal optical microscopy.

What was particularly surprising to the research team was the pronounced work hardening exhibited by these colloidal crystals, outstripping the capacity of traditional metals such as copper and aluminum. Seongsoo Kim, a graduate student involved in the research, noted that the simplicity of particle interactions in colloidal systems defied initial expectations. The team discovered that the mechanisms behind work hardening in these soft materials were principally governed by particle geometry and defect interactions.

As they applied strain to these colloidal crystals, researchers could quantify the movements of millions of particles and observe the interactions responsible for the strengthening process. The results indicated that these ultra-soft materials could embody a surprisingly high degree of strength due to their unique configuration of dislocation defects.

Universal Implications for Materials Development

The implications of this research extend beyond colloidal crystals. The discoveries concerning the universal mechanisms of work hardening have the potential to inform material science across various platforms, even those inaccessible to traditional microscopy. Understanding how a material’s defect density can impact its overall strength opens up new possibilities for engineering applications and the development of innovative materials.

David A. Weitz, a prominent physicist and co-author of the study, reinforced the significance of this research in understanding fundamental material behavior. “Even though these are soft materials, work hardening transforms them into some of the strongest substances known,” he remarked. This new revelation not only enhances our comprehension of existing materials but also lays the groundwork for creating future materials that capitalize on these principles for improved performance in industrial applications.

As researchers continue to unlock the secrets of work hardening, the bridge between ancient craftsmanship and modern engineering grows increasingly defined. The recent findings at Harvard serve not only as a tribute to pioneering scientific inquiry but also as a springboard toward innovative practices in materials design. With potential benefits ranging from enhanced structural integrity in manufacturing to novel applications in diverse fields, understanding work hardening represents a significant leap forward in material science. The journey of these soft colloidal crystals, now identified as exceptional exemplars of strength, highlights the vast potential hidden within the realm of materials yet to be fully understood.

Leave a Reply