The field of programmable photonic integrated circuits (PPICs) has seen significant progress in recent years. PPICs offer faster, more efficient, and massively parallel computing capabilities when compared to conventional supercomputers that rely on electric current. Researchers from the Daegu Gyeongbuk Institute of Science and Technology (DGIST), in collaboration with the Korea Advanced Institute of Science and Technology (KAIST), have made a groundbreaking achievement in incorporating microelectromechanical systems (MEMS) into PPICs. Their research, published in the journal Nature Photonics, highlights the potential of PPICs in various fields such as artificial intelligence, neural networks, quantum computing, and communications.

The integration of MEMS into PPICs marks a significant advancement in the field. MEMS are tiny components capable of interconverting optical, electronic, and mechanical changes to perform essential functions in an integrated circuit. The DGIST team is the first to successfully integrate silicon-based photonic MEMS technologies onto PPIC chips while maintaining extremely low power requirements. By reducing the power consumption to femtowatt levels, a million times improvement compared to the previous state of the art, the team has effectively enhanced the efficiency and performance of PPICs. Additionally, the technology allows for the production of smaller chips, up to five times smaller than existing options.

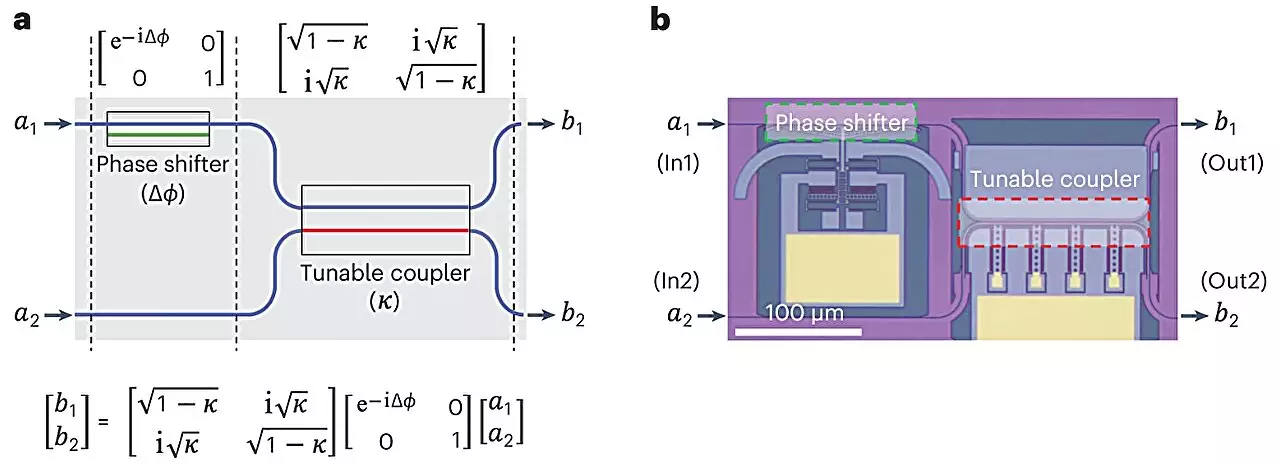

The reduction in power consumption and size is a crucial aspect of the research conducted by the DGIST team. Traditional PPICs relying on “thermo-optic” systems often require temperature changes, leading to higher power demands. However, the team’s innovation eliminates this dependence by incorporating tiny mechanical movements powered by electrostatic forces. These forces, generated by the attractions and repulsions between fluctuating electric charges, provide the necessary energy for the components integrated into the PPIC chips. The ability to manipulate the “phase” of light waves and control the coupling between parallel waveguides enables the construction of fully programmable integrated circuits.

To achieve their groundbreaking results, the DGIST team developed innovative concepts for fabricating silicon-based parts. By utilizing conventional silicon wafer technology, the manufacturing process becomes compatible with large-scale production, making it ideal for commercial applications. This achievement paves the way for the future development and commercialization of photonic computers that surpass the capabilities of conventional electronic computers in various domains.

The success achieved by the DGIST team opens up new possibilities in computational technology. The potential applications of PPICs include crucial inference tasks in artificial intelligence, advanced image processing, and high-bandwidth data transmission. The team plans to further refine their technology and work towards the commercialization of photonic computers. By continuing to push the boundaries of photonics, DGIST aims to contribute to the advancement of modern technology and its practical applications.

The integration of MEMS into PPIC chips represents a significant advancement in the field of programmable photonic integrated circuits. The achievement by the DGIST team, in collaboration with KAIST, has led to a major reduction in power consumption and size while maintaining superior computational capabilities. With the potential to outperform conventional electronic computers, PPICs offer exciting prospects in artificial intelligence, image processing, and data transmission. The ongoing research and refinement of this technology will undoubtedly shape the future of computational technology and its practical applications across various industries.

Leave a Reply