In a groundbreaking development, researchers have successfully converted a waste material from wood into a transparent film that can be used to create anti-fogging and anti-reflective coatings for glasses or vehicle windows. This innovative approach not only offers a safer alternative to the toxic synthetic materials currently in use but also transforms a waste product into a valuable carbon sink. The study, carried out as part of FinnCERES, the Academy of Finland’s flagship center for materials bioeconomy research, was published in the Chemical Engineering Journal.

Lignin, an abundant waste product in paper and pulp production, has traditionally been burned for heat due to its challenging processing nature. While the concept of using lignin nanoparticles for coatings is not new, previous attempts have failed to achieve transparent films. Determined to overcome this hurdle, lead author Alexander Henn, a doctoral researcher, embarked on a mission to minimize the particle size.

An Unexpected Discovery

Using acetylated lignin, the research team developed an improved method to esterify it at a relatively low temperature of 60°C, within a few minutes. The particles created from the acetylated lignin exhibited surprising properties, leading to unexpected opportunities. For example, the team discovered the possibility of manufacturing photonic films, providing new avenues for application. The expertise of researchers Paula Nousiainen and Kristoffer Meinander in lignin chemistry and photonic phenomena, respectively, played a crucial role in understanding and leveraging these unforeseen results.

Expanding Applications

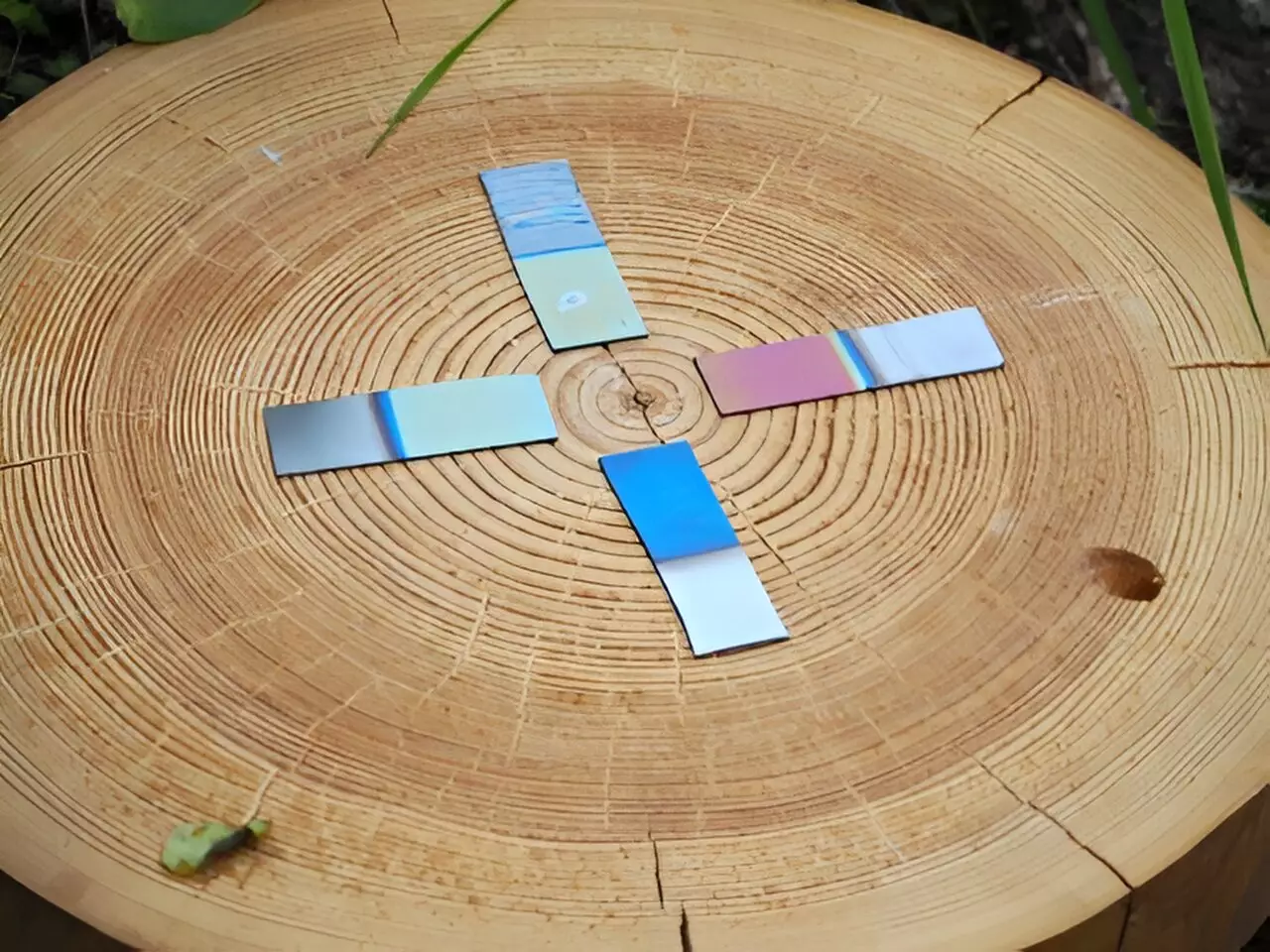

The novel approach not only enables the creation of anti-fogging and anti-reflective coatings but also facilitates the production of colored films from lignin nanoparticles. By controlling the coating’s thickness and utilizing multi-layer films, materials with different structural colors can be achieved. Sahar Babaeipour’s contributions in controlling the particles’ photonic properties were instrumental in this aspect.

The team’s feasibility study indicates that the reaction’s ease and high yield make it economically viable for scaling up to industrial levels. Furthermore, the utilization of lignin-based products could provide commercial value while acting as carbon sinks, thereby reducing fossil fuel dependence and carbon dioxide emissions. Professor Monika Österberg highlights the need for high value-added applications to drive lignin valorization and move away from using lignin solely as a fuel.

The success of this study can be attributed to the collaborative effort of researchers from various fields. Professor Pekka Oinas and doctoral researcher Susanna Forssell played crucial roles in the inclusion of techno-economic analysis, ensuring the study’s practical application beyond the laboratory setting. Henn emphasizes the importance of teamwork in making this research impactful and successful.

The development of bio-based transparent films from wood waste represents a significant step towards a more sustainable and environmentally friendly future. By tapping into the immense potential of lignin nanoparticles, researchers have demonstrated the feasibility of creating valuable materials while mitigating carbon emissions. This innovative approach opens up new avenues for the utilization of lignin and paves the way for a circular economy within the wood industry. As scientists continue to explore and refine this technology, the transformation of waste materials into valuable products will contribute to a greener and more sustainable world.

Leave a Reply