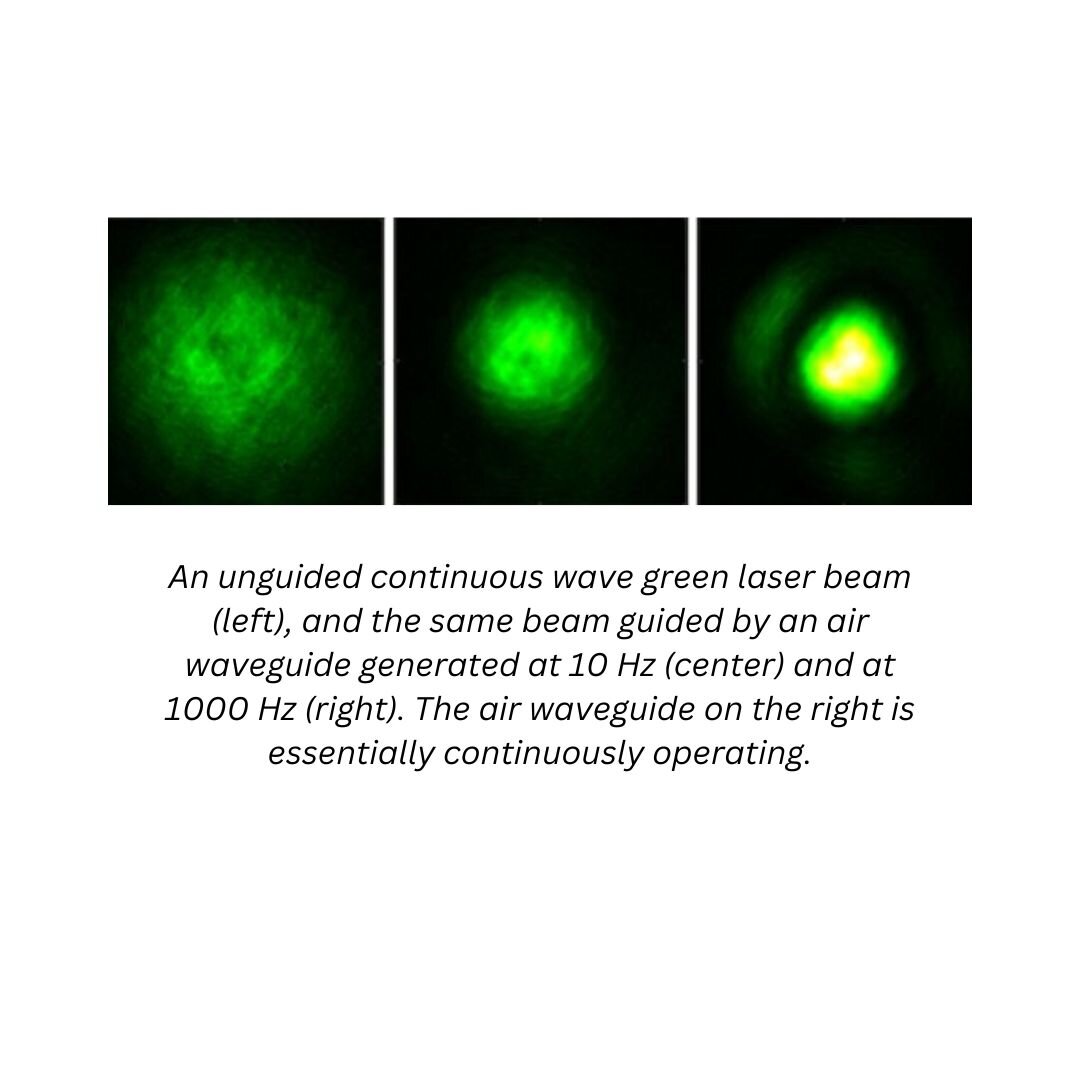

Researchers at the University of Maryland (UMD) have come up with a new way of optical guiding using auxiliary ultrashort laser pulses to form a ring of high-intensity light structures called “filaments.” These filaments heat the air molecules to create an extended ring of low-density heated air that surrounds a central undisturbed region, which is the same as the refractive index structure of an optical fiber. This new technique beats the limitations of glass fibers since the air itself acts as the fiber, and very high average powers can be guided, making it an exceptional candidate for directed energy.

Overcoming Limitations of Glass Fibers

Glass fibers are not well-suited for guiding extremely high-power laser beams since they damage glass and scatter laser energy out of the fiber. Additionally, the need for a physical support structure means that glass fiber must be laid down long before light signal transmission or collection. The new method developed by Howard Milchberg and his group in UMD’s Departments of Physics and Electrical & Computer Engineering and Institute for Research in Electronics & Applied Physics overcomes both these limitations by using air as the fiber and enabling the guiding of very high average powers.

Continuous Air Waveguiding Over Kilometer and Longer Ranges

The waveguide method is scalable to 1 kilometer and longer. The waveguide-generating laser fires a pulse every millisecond, allowing for the air waveguide to be continuously maintained by heating and deepening the waveguide faster than the surrounding air can cool it. The result is a continuously operating air waveguide that can guide an injected continuous wave laser beam. Continuous wave optical guiding significantly improves the utility of air waveguides, increasing the maximum average laser power that can be transported, and maintaining the guiding structure for use in continuous collection of remote optical signals.

Future Potential of the Technology

This new technology has the potential to transmit high power continuous laser beams and detect pollutants from miles away. With an appropriate laser system for generating the waveguide, long-distance continuous guiding should be easily achievable. “Once we have that, it’s just a matter of time before we’re transmitting high power continuous laser beams and detecting pollutants from miles away,” said Andrew Goffin, a graduate student involved in the research. Overall, this new method of optical guiding has the potential to revolutionize the way we think about long-distance light transmission and collection.

Leave a Reply