Researchers at the University of Bristol have developed a new device made from a simple sponge that can help robots grasp objects more delicately, by mimicking the nuanced touch, or variable stiffness, of a human hand. The device can be used to improve the load capacity of soft robots or reduce damage on hard robots. The findings were published at the IEEE International Conference on Robotics and Automation (ICRA) in 2023.

Improved Grasping

Despite the impressive capabilities of modern robots, they can struggle with simple tasks such as holding an egg due to their rigidity. The researchers found that variable stiffness was the key to improving this. Humans have soft tissues surrounding their rigid bones that can naturally mitigate force. Robots lack this nuance. The team’s solution was to develop a soft device that can be mounted on the end of a robotic arm to make contact with objects safer.

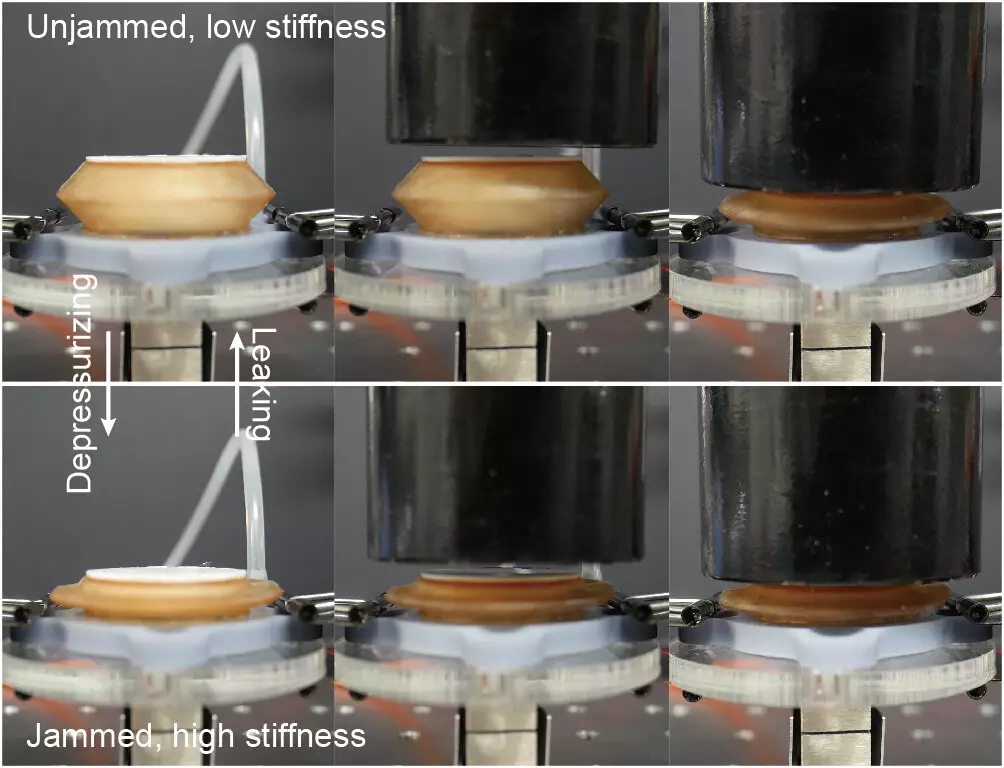

The researchers used silicone sponge to create the device. This is a porous elastomer, similar to a cleaning sponge used for everyday tasks. By squeezing the sponge, the stiffness of the device can be altered, making it an effective variable-stiffness device. The sponge is also cheap and easy to fabricate, making it an ideal material for a wide range of applications.

Applications

The device has potential applications in a range of industries, including manufacturing and healthcare. In industrial settings, the device could be used to grip jellies, eggs, and other fragile substances. In healthcare, the device could be used in ultrasound imaging and robotic polishing, where tunable-stiffness requirements are essential.

Lead author Tianqi Yue from Bristol’s Department of Engineering Mathematics believes that the sponge device has great potential due to its low cost and light weight. The team is now looking at making the device achieve variable stiffness in multiple directions, including rotation.

The researchers at the University of Bristol have developed a novel solution to improve robots’ ability to grasp objects delicately. By using a simple sponge, they have created a variable-stiffness device that can be used in a range of industries and healthcare settings. The device’s low cost and light weight make it an attractive option for a wide range of applications.

Leave a Reply