The production of aluminum has long been recognized as a major contributor to environmental pollution, generating approximately 180 million tons of toxic red mud annually. However, scientists at the Max-Planck-Institut für Eisenforschung have pioneered a groundbreaking method to transform this waste into green steel, providing a promising solution to the pressing environmental issues associated with aluminum production.

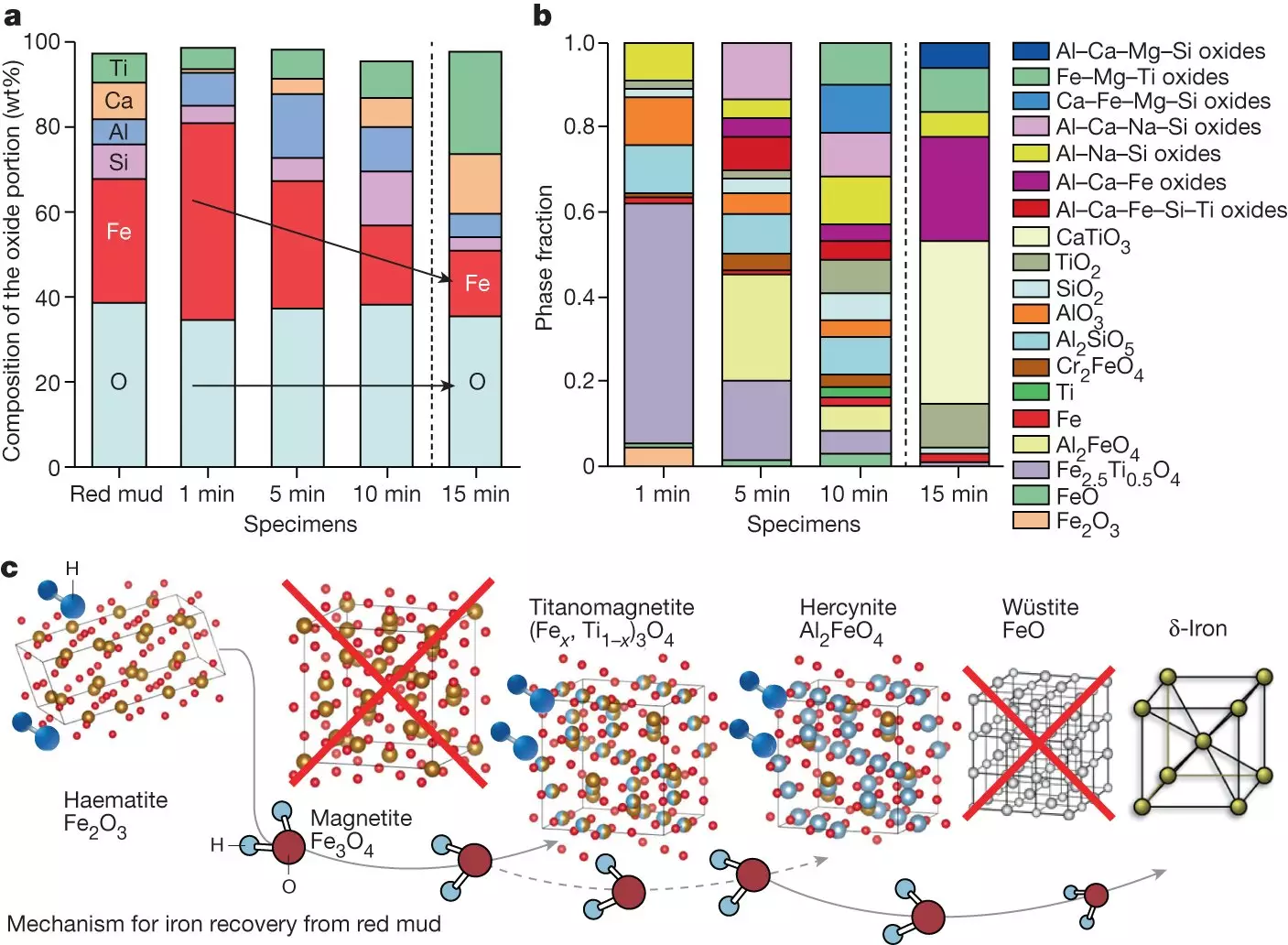

In their research, the Max Planck team demonstrated that by utilizing an electric arc furnace similar to those already widely employed in the steel industry, they can convert the iron oxide present in red mud into iron using hydrogen plasma. This conversion process, known as plasma reduction, effectively turns the environmentally harmful red mud into a valuable resource for steel production.

With this innovative technique, it is estimated that nearly 700 million tons of CO2-free steel could be produced from the accumulated 4 billion tons of red mud worldwide. Not only does this account for a significant portion of the annual global steel production, but it also offers immense potential to mitigate the environmental impact of steel and aluminum manufacturing.

The conventional production of steel and aluminum has long been a cause for concern due to its substantial contribution to greenhouse gas emissions. Currently, the steel industry alone accounts for 8% of global CO2 emissions, making it one of the most polluting sectors. Additionally, the aluminum industry generates an alarming 180 million tons of red mud annually, leading to high processing costs, environmental disasters, and soil contamination.

Countries such as Australia, Brazil, and China resort to drying and storing the red mud in massive landfill sites, which, unfortunately, results in potential leaks and the dispersion of the toxic material during heavy rainfall or wind. Moreover, the highly alkaline nature of red mud corrodes the concrete walls of these landfills, exacerbating the risk of environmental disasters.

The utilization of red mud as a raw material in the production of green steel presents a unique opportunity to simultaneously address the waste issue of aluminum production and reduce the carbon footprint of the steel industry. Researchers at the Max-Planck-Institut für Eisenforschung have demonstrated that through plasma reduction, the iron oxide within red mud can be converted into pure iron, which can then be used directly in steel production.

Furthermore, the remaining metal oxides solidify into a glass-like material that can be utilized in the construction industry. This dual approach not only ensures the efficient utilization of resources but also provides a way to contain and neutralize heavy metals present in the red mud.

The environmental benefits of this sustainable steel production method are significant. By utilizing green hydrogen as a reducing agent, the process avoids the emission of large quantities of CO2 associated with conventional approaches utilizing coke. In fact, if green hydrogen were employed in the production of iron from the 4 billion tons of red mud already created, the steel industry could potentially save nearly 1.5 billion tons of CO2 emissions.

Moreover, the economic viability of this innovative technique has been demonstrated through comprehensive cost analysis. The utilization of hydrogen and a partially renewable electricity mix for the electric arc furnace proves economically advantageous, particularly when the red mud contains 50% or more iron oxide. Additionally, considering the costs associated with red mud disposal, the process becomes economically feasible even with only 35% iron oxide.

The advantages of this sustainable steel production method go beyond environmental and economic considerations. The utilization of electric arc furnaces, which are already commonly used in the metal industry, means that minimal investment is required for steel and aluminum producers to transition to this more sustainable approach. The widespread adoption of this technique has the potential to revolutionize the steel industry and pave the way for a greener future.

“It was important for us to also consider economic aspects in our study,” emphasizes Dierk Raabe, Director at the Max-Planck-Institut für Eisenforschung. By addressing both the environmental and economic concerns associated with steel and aluminum production, the transformation of red mud into green steel represents a step towards a more sustainable and responsible industrial future.

Leave a Reply