In recent years, mycelial fibers have gained recognition as a sustainable alternative to conventional materials. Known for their excellent formability, these fibrous cells found in fruiting mushroom bodies have shown great potential for applications such as leather and packaging. As the world grapples with the growing problem of waste, scientists are seeking out eco-friendly materials that can effectively replace plastic or petroleum-based products. One such solution lies in mushroom-based materials.

The mycelial fibers derived from the root-like fruiting bodies of mushrooms possess several qualities that make them an ideal choice for various consumer and industrial applications. These fibers contain proteins, chitin, and polysaccharides, making them not only versatile but also environmentally friendly. With low environmental impact and a biodegradable nature, mushroom-based materials offer an enticing alternative to traditional options. Furthermore, their low production cost adds to their appeal.

While the potential of mycelium fibers is evident, the process of obtaining them has presented challenges. Conventional extraction methods often result in a loss of the intricate mycelial structures and an undesired coloration of the materials. This limitation restricts their applications on the nanoscale level. To address these shortcomings, a team of researchers from Shinshu University in Japan has developed an innovative approach to obtaining mycelial fibers.

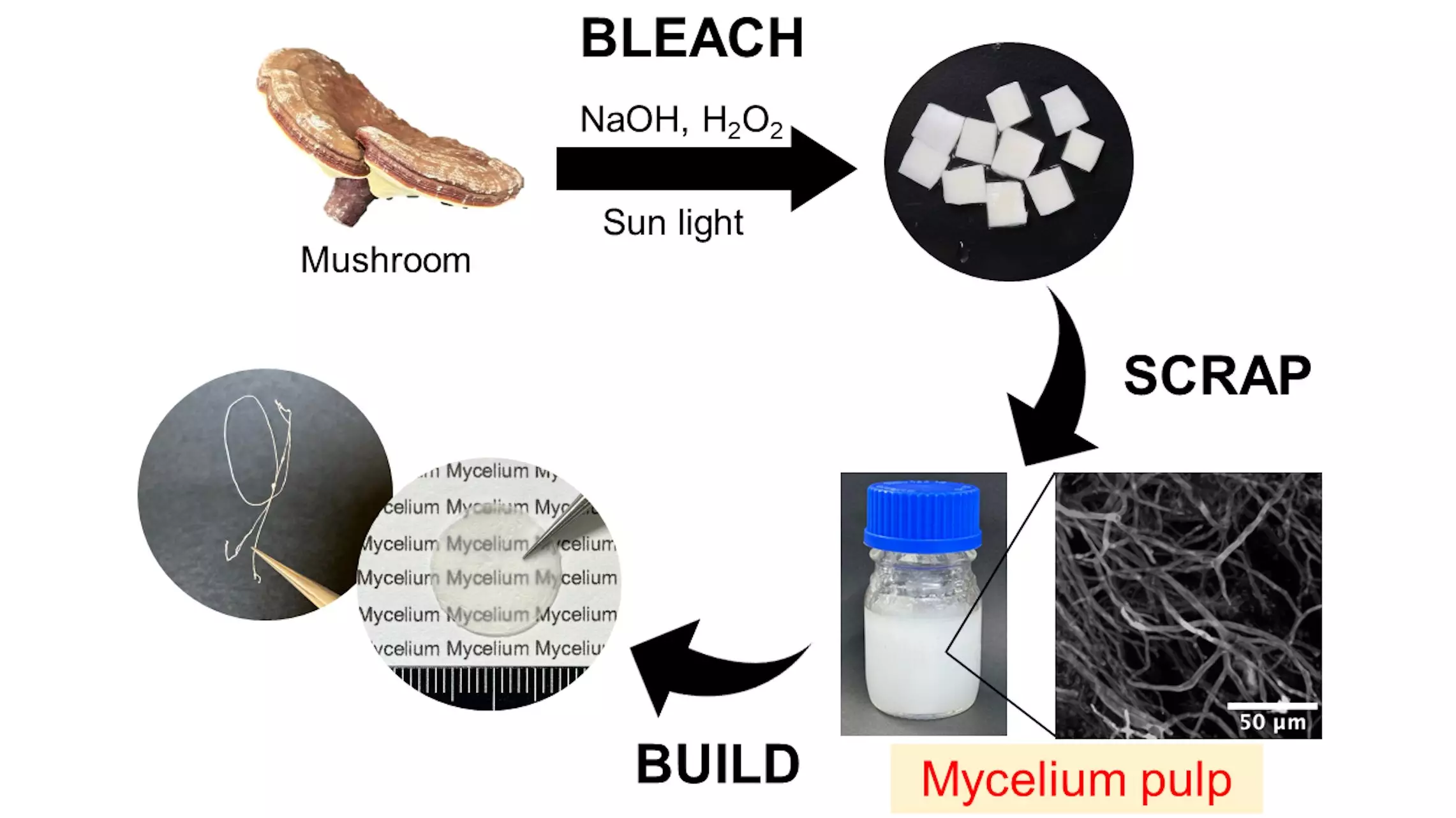

Led by Assistant Professor Satomi Tagawa, the team discovered a straightforward method for extracting mycelial fibers called “mycelial pulp” from fruiting mushroom bodies. The researchers treated enoki and inedible reishi mushrooms with sodium hydroxide and hydrogen peroxide. Subsequently, they exposed the obtained substances to sunlight for bleaching or decolorization. The resulting material, which maintained its mycelial structures, underwent ultrasonic treatment for defibration at the mycelial level.

The mycelium fibers obtained from this process demonstrated excellent deformability. They could be molded into various products, including 3D porous sponges, 2D films, and 1D yarns. This opens up a world of possibilities for designers and manufacturers who prioritize sustainability. Additionally, this simple extraction approach complements existing bottom-up fabrication methods, making it easier to utilize mushroom-based materials.

The technology developed by Dr. Tagawa and her team not only offers a versatile mushroom-based material but also contributes to the concept of a circular economy. By upcycling unwanted by-products generated by the mushroom industry, these materials become easier to reuse and create a more sustainable industry. This breakthrough has the potential to spark new industries, generate employment opportunities, and revitalize local communities.

As the world strives for sustainability, mushroom-based materials emerge as a viable solution for various sectors. From packaging to soundproofing, textiles to 3D printing, the versatility of mycelium fibers knows no bounds. With their low environmental impact, biodegradability, and cost-effective production, these materials are poised to revolutionize multiple industries. Further research into sustainable materials and methods will undoubtedly drive innovation and pave the way for a greener future.

Leave a Reply