Single-use plastics have long been a topic of environmental concern due to their negative impact on ecosystems. However, recent research conducted by the Institute for Chemical Reaction Design and Discovery (WPI-ICReDD) at Hokkaido University has revealed a groundbreaking method that could transform the way we view these plastics. Instead of adding to the already staggering amount of plastic waste, used grocery bags can now be repurposed to detoxify hazardous chemicals.

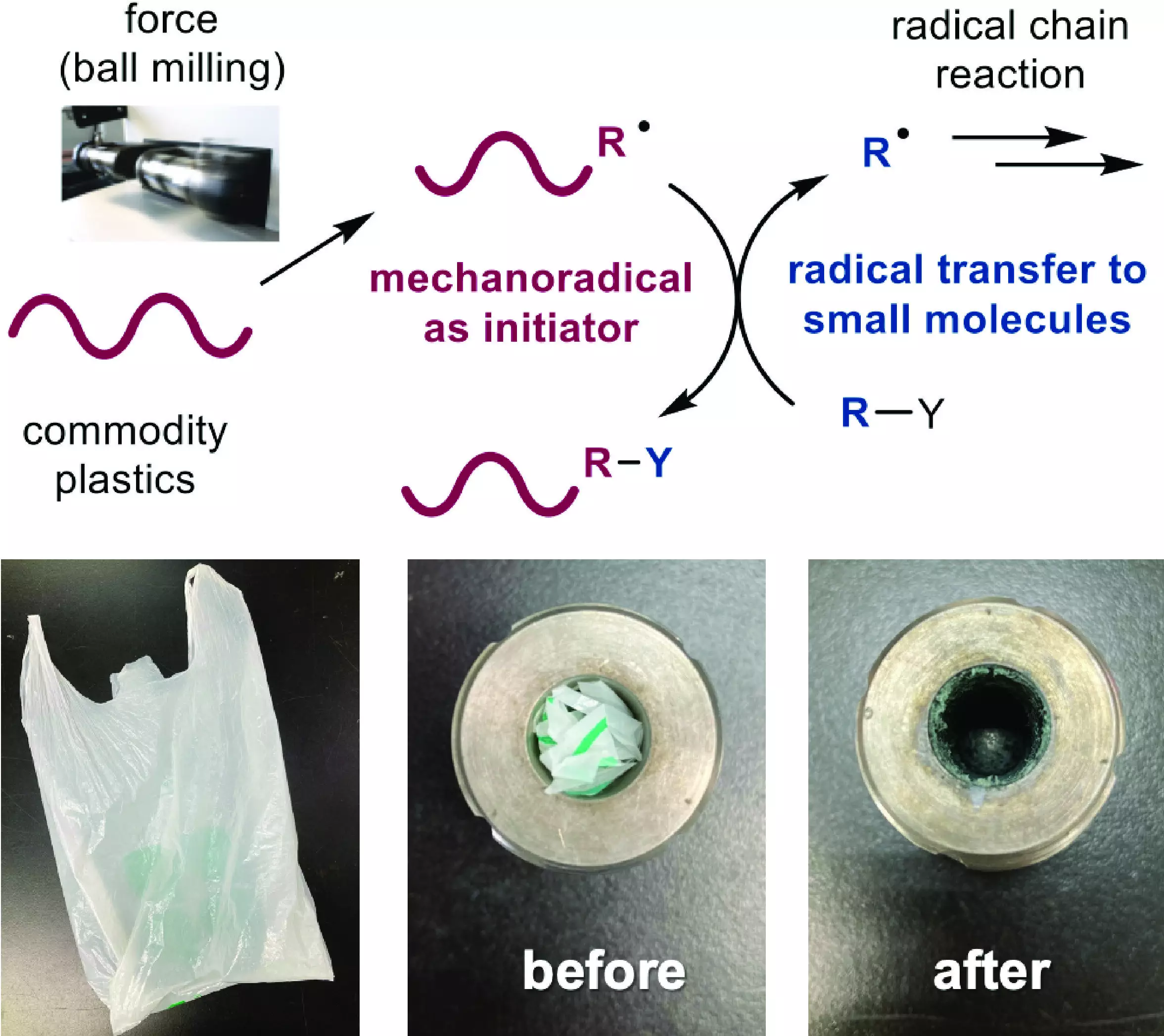

The research team led by Associate Professor Koji Kubota introduced a novel concept of utilizing common plastic materials, such as polyethylene and polyvinyl acetate, as reagents for chemical reactions. By employing a ball mill, which shakes a steel ball inside a steel jar to mix solid chemicals, the team discovered that the mechanical force exerted by the ball on the plastic results in the breaking of chemical bonds. This bond breakage forms highly reactive radicals, which play a crucial role in initiating a self-sustaining chain reaction that promotes dehalogenation—the replacement of a halogen atom with a hydrogen atom in organic halides.

Professor Kubota states that the use of commodity plastics as chemical reagents presents a completely new perspective on organic synthesis. Beyond developing safe and highly efficient radical-based reactions, this approach presents an opportunity to tackle the pressing issue of waste plastics. The ability to reuse plastic waste while addressing social problems is a significant step towards a more sustainable future.

To showcase the potential of this method, the research team added shredded plastic from a common grocery bag to the ball mill jar and successfully carried out the reaction. Furthermore, the team demonstrated that this methodology can be applied to the treatment of highly toxic polyhalogenated compounds, which are extensively used in various industries. By utilizing polyethylene to initiate a radical reaction, the team effectively removed multiple halogen atoms from a flame retardant compound, thereby reducing its toxicity.

The cost-effectiveness and enhanced safety of this approach make it highly attractive to industries looking to optimize their chemical processes. Professor Hajime Ito emphasizes that this revolutionary method, which employs stable, cheap, and abundant plastic materials as initiators for radical chain reactions, holds the potential to revolutionize the field. It offers a path towards industrially attractive, safe, and highly efficient chemical processes.

The study conducted by the WPI-ICReDD at Hokkaido University introduces a groundbreaking use for single-use plastics. By utilizing common plastic materials as reagents in chemical reactions, this innovative approach not only offers a way to detoxify hazardous chemicals but also addresses the mounting concern of plastic waste. With the potential to improve cost-effectiveness and safety in industrial processes, this research marks a significant step towards a more sustainable future.

Leave a Reply