In a groundbreaking development, a team of chemical engineers and materials scientists at Zhejiang University in China has successfully created a new type of aerogel fiber that surpasses the warmth of down when incorporated into a sweater. This remarkable achievement could revolutionize the textile industry and redefine the way we stay warm in cold environments. The team’s findings were recently published in the prestigious journal Science, attracting significant attention from researchers worldwide.

The inspiration behind this project originated from the thermal properties of polar bear fur. These bears have uniquely designed hairs that possess both a dense outer shell and a porous core, enabling them to withstand extremely cold temperatures. Seeking to replicate this remarkable insulation mechanism, the research team embarked on a journey to engineer an encapsulated aerogel fiber.

Previous attempts at developing aerogel fibers have encountered significant challenges due to poor moisture permeability and lack of strength. Despite the positive thermal properties of aerogels, their application in textiles remained elusive. However, the team from Zhejiang University has ingeniously overcome these obstacles, ushering in a new era in warm textiles.

To create their revolutionary fiber, the researchers began with a precursor material, which they spun while in a frozen state. This innovative spinning process triggered a sol-gel transition, resulting in an encapsulated aerogel fiber. The material was subsequently freeze-dried and coated with a semi-hard shell, leading to the formation of thin, round fibers that could be tailored to desired lengths.

An exceptional aspect of this research is the absence of post-processing steps required to produce textiles from the aerogel fibers. This suggests that the production of these warm textiles could be significantly more cost-effective compared to conventional manufacturing methods. The development of a more affordable option holds the potential to make warm clothing more accessible to a broader population.

To gauge the performance of their aerogel fiber, the team produced batches of fibers in long strands and used them to weave a sweater. Subsequently, they conducted rigorous tests to assess its thermal properties. The sweater demonstrated exceptional thermal protection, outperforming traditional sweaters crafted from down, wool, or cotton when subjected to temperatures as low as -20°C.

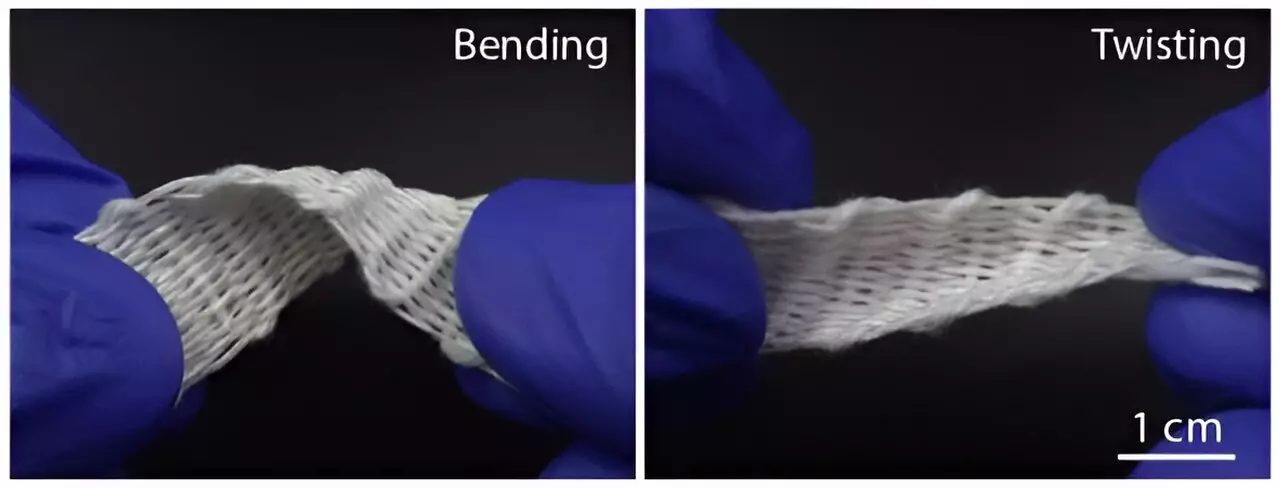

Aside from its impressive warmth, the aerogel fiber also showcased remarkable durability. Despite stretching the sweater 10,000 times, minimal damage was observed. This long-lasting and resilient quality is a significant advantage in the field of textiles, ensuring that garments made from these fibers can withstand the rigors of everyday use.

Furthermore, the researchers discovered that the aerogel fibers can be stretched, dyed, and flexed, opening up endless possibilities for creative designs and applications. This newfound flexibility enables the production of aerogel-based textiles that meet the aesthetic preferences and functional requirements of a diverse range of consumers.

The groundbreaking development of the aerogel fiber marks an extraordinary leap forward in the field of warm textiles. The successful creation of an encapsulated aerogel fiber provides a scalable and cost-efficient solution to the longstanding challenge of incorporating aerogels into textiles. With its exceptional thermal properties, durability, and versatility, this breakthrough has the potential to redefine winter clothing and revolutionize the way we experience cold weather. As the world eagerly awaits further advancements in this field, the future certainly looks warm and cozy.

Leave a Reply