The push for renewable energy sources has led engineers and scientists to explore various technologies for generating electricity. A recent approach that has gained attention is thermoelectric power generation, which converts excess heat into electricity. However, the challenge lies in designing and fabricating optimum module structures to realize the full potential of thermoelectric materials.

Researchers at Pohang University of Science and Technology and the George Washington University have introduced a new strategy for designing thermoelectric materials based on copper selenide (Cu2Se). This innovative approach outlined in a paper published in Nature Energy aims to create high-power generation materials that are easier to reproduce on a large scale.

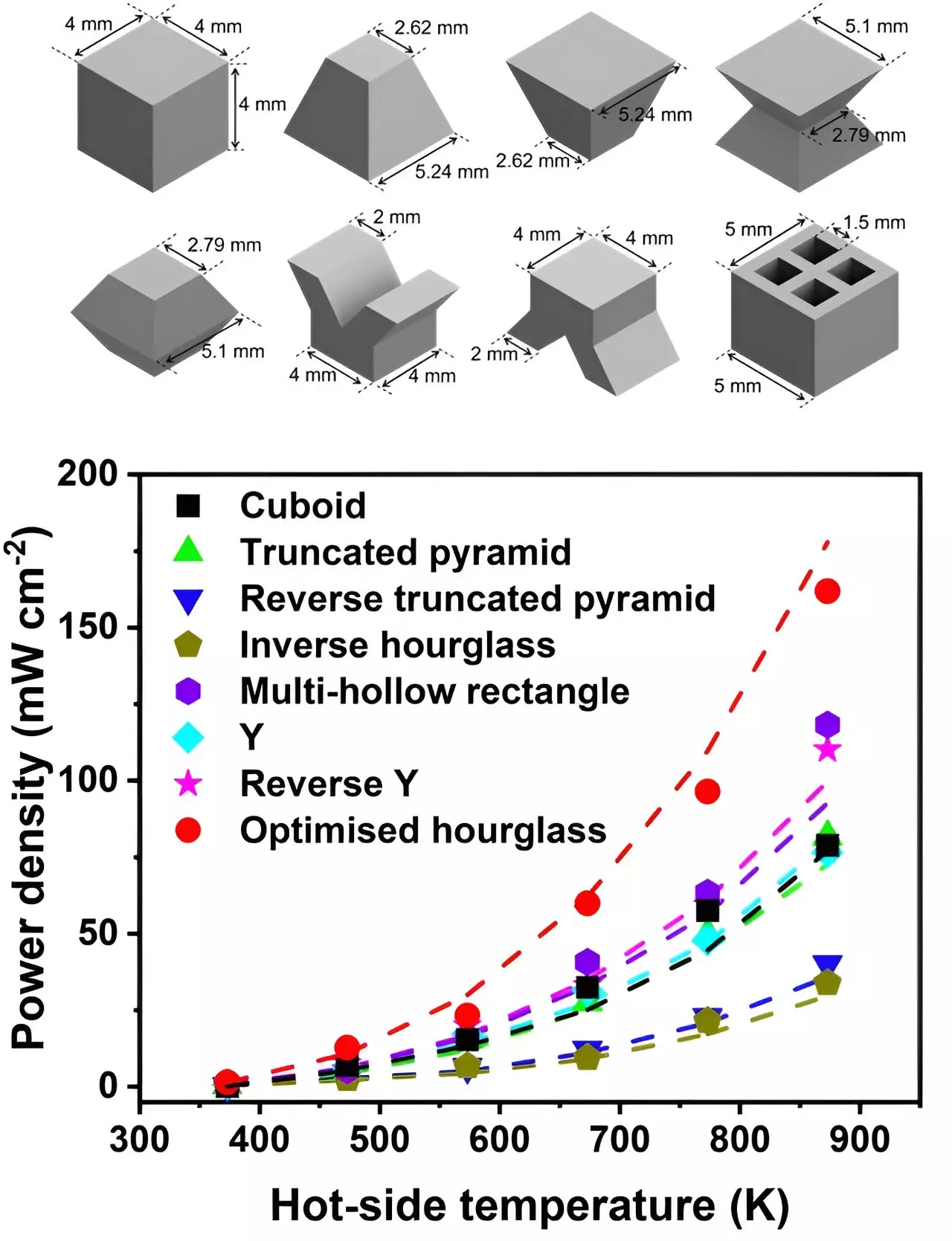

Traditional thermoelectric devices consist of cuboid-shaped semiconductor legs, which are integral to optimizing thermal and electrical resistances for maximum power generation. However, the research team led by Prof. Saniya LeBlanc at the George Washington University has delved into the potential of non-cuboid geometries for enhancing thermoelectric performance. Through numerical simulations and experimental assessments, they sought to understand the impact of complex geometries on power generation.

One of the key aspects of the study involved utilizing 3D printing techniques to fabricate non-cuboid geometries for semiconductor legs. By designing and printing these intricate structures, researchers were able to assess their performance in generating electricity. Cu2Se was chosen as the model material due to its high efficiency at elevated temperatures, enabling the team to evaluate power generation under various conditions.

The experiments conducted by the research team revealed that legs with an hourglass-shaped geometry exhibited the highest power generation output and efficiency. This discovery showcases the potential of non-cubic legs in enhancing thermoelectric performance. Controlled liquid-phase sintering was instrumental in creating defects that reduced thermal conductivity and increased ZT values up to 2.0.

The study by Son and his colleagues underscores the significant impact of 3D geometry on thermoelectric power generation. While their focus was on Cu2Se-based materials, the findings pave the way for applying non-cuboid geometries to other thermoelectric systems. The potential for boosting the performance of thermoelectric power generators without altering intrinsic properties holds promise for future research and innovation.

The exploration of non-cuboid geometries in thermoelectric materials design represents a significant step towards enhancing the efficiency and power generation capabilities of renewable energy sources. By leveraging innovative strategies and advanced techniques such as 3D printing, researchers are poised to unlock new possibilities in sustainable energy generation. The impact of 3D geometry on thermoelectric performance opens doors to further advancements in the field, signaling a bright future for renewable energy technologies.

Leave a Reply