The quest for sustainable and efficient technologies in the field of hydrocarbon valorization has brought about a groundbreaking development. Natural gas, composed of potent greenhouse gases such as methane and ethane, poses significant challenges in terms of storage and conversion. Conventional large-scale facilities for transforming natural gas are costly and impractical for smaller natural gas wells. This has led scientists to pursue cost-effective and environmentally friendly solutions to this global problem.

A research team, headed by Professor Jeffrey R. Long at UC Berkeley and including esteemed researchers from the Mülheim Max Planck Institutes, has unveiled a powerful catalyst that tames the destructive nature of hydrocarbon gases. Inspired by Nature’s enzymes that activate dioxygen for selective hydrocarbon oxygenation reactions, the team sought to mimic their incredible functionality. They focused on α-ketoglutarate dependent dioxygenases, which utilize an α-keto acid as a co-substrate to cleave the oxygen-oxygen bond of dioxygen. This process yields a reactive iron-oxo species capable of oxygenating abundant C-H bonds to produce valuable alcohols.

The team of researchers harnessed the potential of metal-organic frameworks (MOFs), crystalline porous materials composed of organic linkers and metal ions or cluster nodes. MOFs offer immense chemical tunability and provide a platform for tailored heterogeneous catalysts. By designing a MOF catalyst material capable of solid-gas reactions, the team achieved enzyme-like reactivity for hydrocarbon oxygenation at near ambient temperatures utilizing dioxygen. This breakthrough opens up new possibilities for green technologies in hydrocarbon valorization.

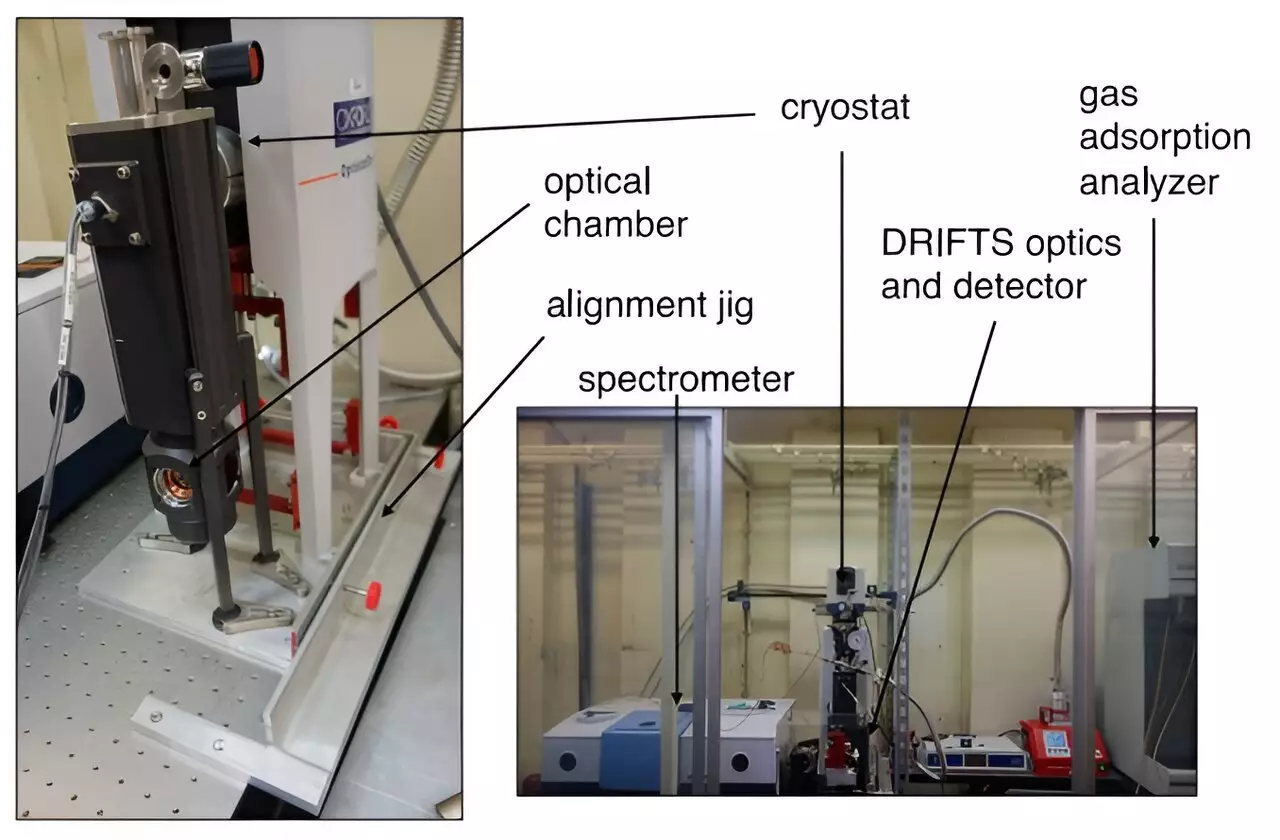

At the Mülheim Chemistry Campus, the reactive intermediate generated from the MOF catalyst and dioxygen was extensively studied. The unique properties of the MOF material allowed for site-isolation of the high-valent iron-oxo species, akin to the TauD-J intermediate in the enzyme taurine dioxygenase. State-of-the-art spectroscopic techniques, including variable-temperature variable-field Mössbauer spectroscopy and Fe Kβ X-ray emission spectroscopy, were employed to investigate this reactive species. The data collected at the PINK X-ray beamline at BESSY II at the Helmholtz-Zentrum Berlin für Materialien und Energie, combined with advanced computational methods, confirmed the structural and electronic similarities between the high-spin iron-oxo intermediate and TauD-J. Remarkably, this is the first non-enzymatic system to successfully oxidize light hydrocarbons with dioxygen, mirroring the reactivity of metalloenzymes.

The development of this novel MOF catalyst marks a significant milestone in the field of natural gas conversion. Its cost-effectiveness and benign properties make it a promising technology for global adoption. The ability to efficiently transform natural gas into valuable alcohols at near ambient temperatures brings us closer to a sustainable future. By harnessing the power of enzyme-like reactivity, this breakthrough catalyst paves the way for green alternatives in hydrocarbon valorization.

The relentless pursuit of innovative solutions has led scientists to unlock the potential of natural gas conversion. By leveraging the concept of enzyme reactivity and applying it to a tailored MOF catalyst, researchers have achieved remarkable results. The new catalyst material enables the selective oxygenation of hydrocarbons, offering a green and cost-effective approach to hydrocarbon valorization. This breakthrough is a promising step towards a more sustainable future, where natural gas can be harnessed efficiently and responsibly.

Leave a Reply