The emergence of 3D-printed concrete technology is revolutionizing the construction industry by offering quick, precise, and eco-friendly building solutions. However, the limitations in printable material options and concerns about sustainability and durability have remained key challenges in this innovative field.

Researchers at the University of Virginia School of Engineering and Applied Science have made a groundbreaking discovery by investigating the use of cellulose nanofibrils as an additive to enhance 3D-printed concrete. This plant-based material, derived from wood pulp, has shown promising results in improving the flow properties and mechanical strength of composite materials.

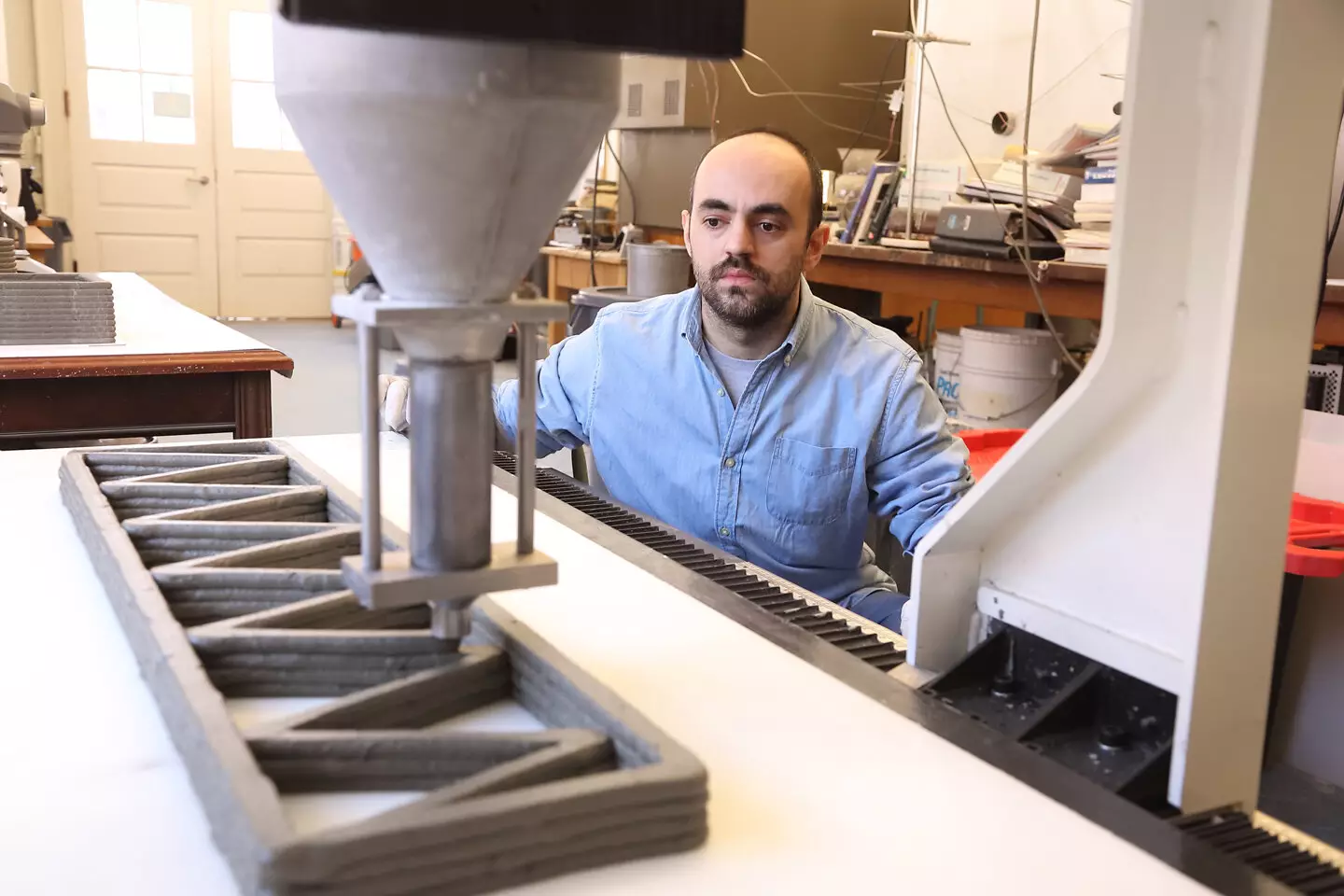

Led by Professor Osman E. Ozbulut and Ph.D. alumnus Ugur Kilic, the research team conducted a meticulous study to assess the impact of cellulose nanofibrils on 3D-printed concrete composites. The results, which will be published in the September 2024 issue of Cement and Concrete Composites, demonstrate significant enhancements in both printability and mechanical performance with the addition of CNF.

Cellulose nanofibrils offer a renewable and low-impact alternative to traditional additives used in construction materials. Their ability to improve the rheology and structural integrity of 3D-printed concrete makes them a valuable resource for creating more resilient and sustainable building practices.

By incorporating cellulose nanofibrils into printable materials, construction companies can achieve a dual benefit of reducing environmental impact and enhancing structural durability. The findings of this study pave the way for a more sustainable future in the construction industry.

The research conducted by the University of Virginia engineering team highlights the potential of cellulose nanofibrils in improving the performance of 3D-printed concrete structures. As the demand for sustainable construction practices continues to grow, innovative solutions like CNF additives offer a promising path towards greener and more resilient buildings.

Leave a Reply