In a rapidly evolving technological landscape, the demand for rare earth elements (REEs) is expected to soar. These metals, such as dysprosium and neodymium, play a crucial role in modern electronics due to their unique properties. While they are not as scarce as precious metals like platinum or gold, their extraction and purification pose significant challenges. The current methods involve complex and inefficient processes, resulting in high levels of chemical waste. However, a recent breakthrough by a team of researchers led by chemistry professor Justin Wilson offers a promising solution to this predicament.

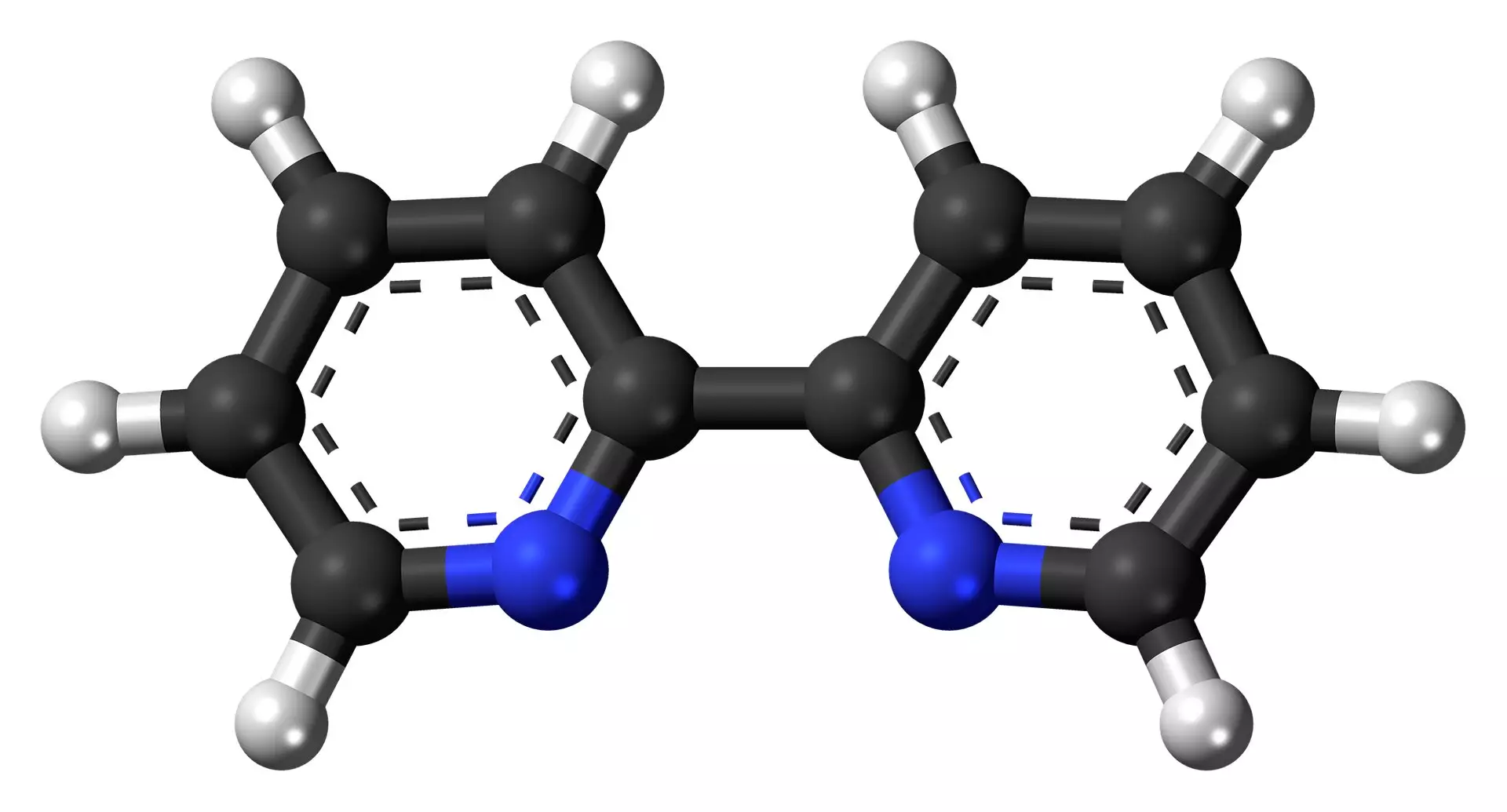

Wilson and his team have developed a revolutionary technique to purify REEs at room temperature without the use of toxic compounds. Their method, published in the journal Angewandte Chemie International Edition, involves a new approach that eliminates the need for organic solvents, which are often hazardous and environmentally damaging. By utilizing a specific chelator called G-macropa, the researchers were able to achieve a remarkable concentration of dysprosium by a factor of over 800, as opposed to less than 10 with conventional liquid-liquid extraction methods.

The Advantages of the New Process

The innovative purification process developed by Wilson and his team offers several advantages over traditional methods. By utilizing a more efficient chelator and eliminating the use of organic solvents, the new technique reduces waste generation and minimizes environmental impact. Moreover, the ability to recover pure REEs from mining operations and electronic waste opens up opportunities for sustainable recycling practices. This not only addresses the environmental concerns associated with traditional extraction methods but also provides a cost-effective alternative for obtaining these critical minerals.

The implications of this groundbreaking research extend beyond the laboratory. The newfound efficiency in separating REEs could revolutionize the supply chain for these metals, particularly in countries like the United States. With significant deposits of REEs within its borders, the U.S. has the potential to reduce its reliance on imports, particularly from countries like China where environmental regulations are less stringent. By enabling a cleaner and more efficient way of processing these metals, Wilson’s research could pave the way for domestic production of rare earth elements, bolstering national security and stimulating economic growth.

Looking ahead, Wilson and his team are focused on refining their technique and exploring new avenues for separating REEs. By collaborating with experts in the field, they aim to optimize the chelator design and develop cost-effective alternatives for industrial applications. The ultimate goal is to scale up the process to handle high concentrations of REEs and adapt it to different compositions of rare earth elements. Through ongoing research and innovation, Wilson’s team is working towards a sustainable and efficient solution for meeting the growing demand for these essential metals.

The development of a cleaner and more efficient separation process for rare earth elements marks a significant advancement in the field of materials science. By addressing the challenges associated with REE extraction and purification, Wilson and his team are paving the way for a more sustainable and environmentally friendly future. As the demand for these metals continues to rise, innovative approaches like the one pioneered by Wilson offer a promising solution to ensure a stable supply chain and reduce our reliance on conventional extraction methods.

Leave a Reply