Electric vehicles (EVs) have become a popular and eco-friendly mode of transportation, but many of them rely on batteries that contain cobalt. Cobalt, a valuable metal that is commonly used in lithium-ion batteries, comes with significant financial, environmental, and social costs. However, researchers at MIT have developed a new battery material that could provide a more sustainable alternative to power EVs. By replacing cobalt with an organic-based cathode, this breakthrough battery material offers comparable performance to its cobalt counterparts, while being more cost-effective and environmentally friendly.

Cobalt-based batteries, although efficient, come with several downsides. Cobalt is a scarce metal, leading to price fluctuations and dependence on politically unstable countries for its extraction. The mining of cobalt also has severe environmental and social consequences, including hazardous working conditions and toxic waste contamination. As the demand for EVs continues to rise, the cost of cobalt batteries is expected to increase even further. Due to these drawbacks, researchers have been actively seeking alternative battery materials to overcome these challenges.

Organic materials have long been considered a potential solution for sustainable battery technology. However, most organic materials have not been able to match the conductivity, storage capacity, and lifetime of cobalt-containing batteries. The main issue with organic materials is their low conductivity, which requires them to be mixed with polymers as binders to maintain a conductive network. Unfortunately, these binders decrease the battery’s storage capacity.

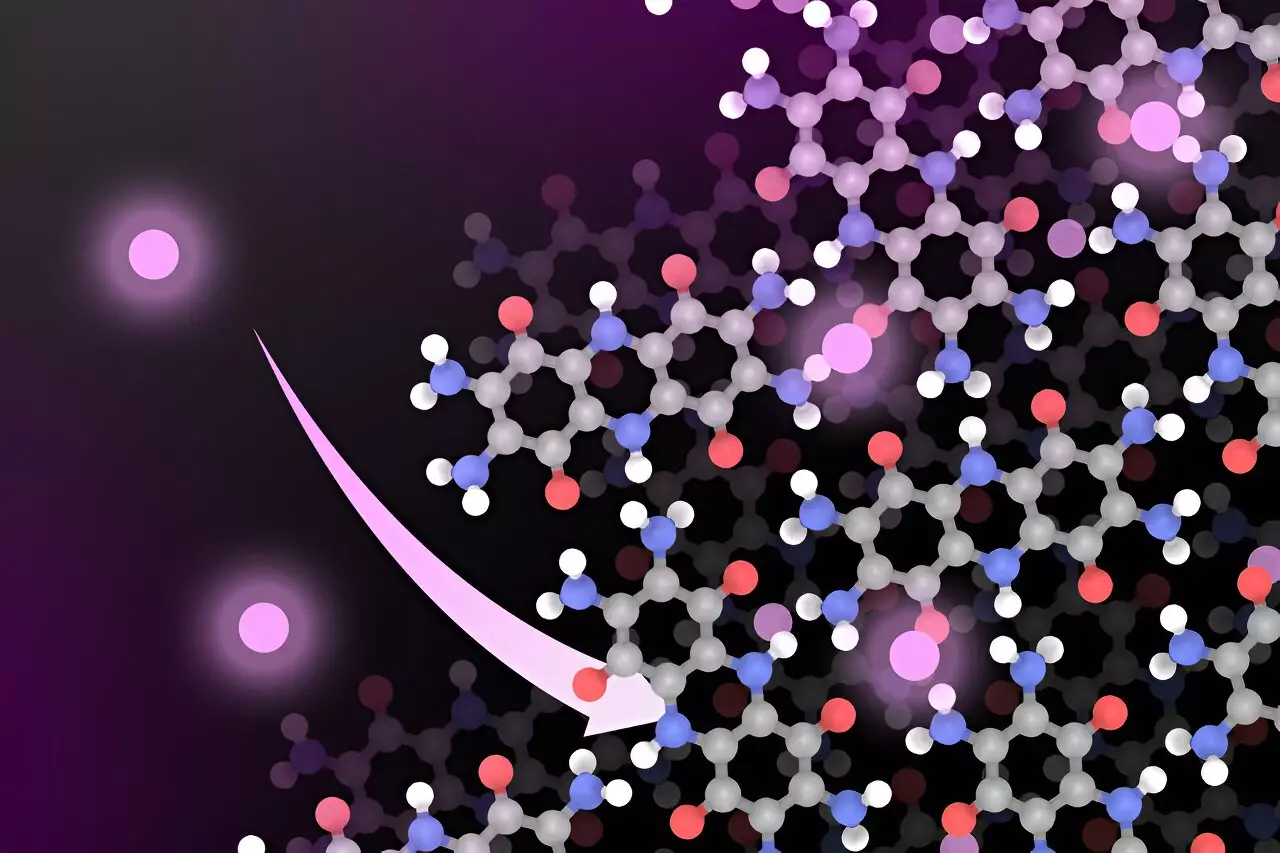

Several years ago, researchers at MIT began a project to develop an organic battery for EVs. Through their research, they discovered a fully organic material that showed promise as a strong conductor. This material, known as bis-tetraaminobenzoquinone (TAQ), consists of layers of organic molecules that form a stable structure similar to graphite. The material’s insolubility prevents it from dissolving into the battery electrolyte, extending its lifetime and allowing for over 2,000 charge cycles with minimal degradation.

Matching Performance with Cost

Tests of the TAQ cathode material showed that it has comparable conductivity and storage capacity to traditional cobalt-containing batteries. Furthermore, batteries with the TAQ cathode can be charged and discharged at a faster rate, potentially reducing the charging time for EVs. To improve the material’s stability and adhesion to the battery’s current collector, researchers added filler materials such as cellulose and rubber. These fillers, which make up a small fraction of the overall cathode composite, do not significantly reduce the battery’s storage capacity.

One of the most significant advantages of this new battery material is its cost-effectiveness. The primary materials required for manufacturing the cathode, the quinone precursor, and the amine precursor, are already commercially available and produced in large quantities as commodity chemicals. The researchers estimate that the cost of assembling these organic batteries could be as low as one-third to one-half of cobalt batteries. This cost reduction makes them a more viable option for mass-producing affordable EVs.

The patent for this battery technology has already been licensed by Lamborghini, signaling its commercial potential. However, the MIT researchers are not stopping there. They plan to continue exploring alternative battery materials and are investigating the possibility of replacing lithium with sodium or magnesium, which are cheaper and more abundant resources. By pushing the boundaries of battery technology, they aim to make EVs even more accessible and sustainable.

A Brighter Future for Electric Cars

With the development of this sustainable battery material, the future of electric vehicles looks even more promising. By eliminating the reliance on cobalt, these batteries can mitigate the environmental and social impacts associated with its extraction. Additionally, the lower cost of production makes EVs more affordable, accelerating their adoption and reducing carbon emissions from transportation. As researchers and industry leaders continue to innovate, we can look forward to a greener and more sustainable future for electric cars.

Leave a Reply