Alkylbenzene is a crucial component in the manufacturing of detergents, including soap, toothpaste, laundry detergent, and industrial cleaners. However, traditional methods of alkylbenzene production generate harmful halogen byproducts. In an effort to develop a more sustainable and cost-effective manufacturing process, researchers have devised a new technique using alkanes directly as alkylating agents. This groundbreaking approach offers numerous advantages, including increased efficiency, reduced waste generation, and a more environmentally friendly alternative to conventional methods.

The Challenge of Alkanes

Alkanes, which consist entirely of carbon and hydrogen atoms bonded together by carbon-carbon and carbon-hydrogen single bonds, pose a challenge in chemical transformations due to their highly stable carbon-hydrogen bonds. Methane, ethane, propane, and butane are common examples of alkanes, with crude oil and natural gas being the primary sources of these compounds. Alkanes are generally difficult to use directly for selective chemical reactions.

Traditionally, alkylbenzenes are produced through a series of two to three steps, involving additional compounds called alkylating agents. These agents, derived from alkanes in multiple steps, are necessary for the alkylation of benzene, which is the process of adding an alkyl group. However, this multi-step process is both costly and wasteful. Moreover, the use of classical Friedel-Crafts reactions often results in the formation of toxic halogen byproducts.

To address the limitations of traditional methods, researchers investigated the feasibility of using simple alkanes directly as alkylating agents for alkylbenzene synthesis. This approach not only aims to reduce costs but also promises to minimize waste generation and streamline production, offering a more sustainable alternative. Professor Ken Motokura, the lead author of the study, highlights the potential for this new technique to be more environmentally friendly than conventional methods.

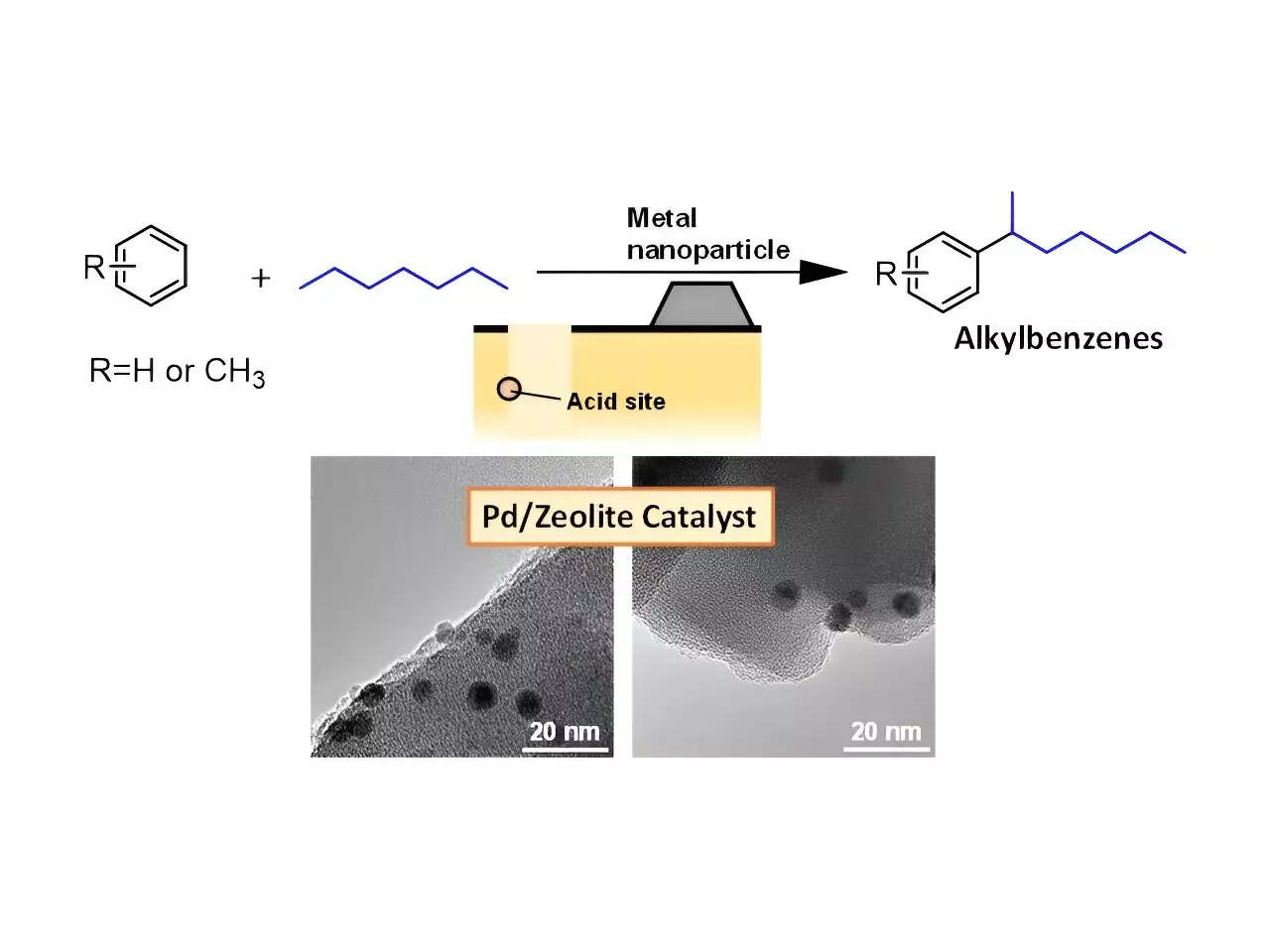

In order to achieve the desired efficiency, the development of novel catalysts was crucial. The researchers discovered that palladium nanoparticles, situated on the outer surface of H-ZSM-5 zeolites, functioned as highly efficient catalysts for direct alkylation. Zeolites are crystalline materials composed of aluminum and silicon, with microscopic pores that serve as sites for chemical reactions. These catalysts enable the activation of alkanes within the zeolite pores, preparing them for the addition of benzene, an organic compound shaped like a ring. This results in the production of alkylbenzene.

During this process, two hydrogen atoms (H) are removed from the alkane and benzene. To regenerate the active sites inside the zeolite, these hydrogen atoms must be recombined into a hydrogen molecule (H2). A fascinating phenomenon known as “hydrogen spillover” occurs, where hydrogen atoms migrate from the activation sites to the palladium nanoparticles on the outer surface, facilitating the recombination into H2. This phenomenon enhances the efficiency and selectivity of the alkylation process.

Selectivity and Efficiency

One of the significant advantages of direct alkylation is its impressive selectivity. The researchers were able to achieve an impressive 95.6% selectivity for the desired alkylated products. This means that the technique can produce the desired output while minimizing the formation of less desirable byproducts. However, despite these efficiency gains, the overall yield from the process remains insufficient for large-scale industrial applications. Therefore, the research team is now focusing on refining and optimizing their technique to increase productivity.

The Future of Alkylbenzene Production

The development of a more efficient, cost-effective, and environmentally friendly manufacturing process for alkylbenzene holds immense potential. By utilizing alkanes directly as alkylating agents and employing novel catalysts, researchers have taken a significant step towards addressing the limitations of conventional methods. As further advancements are made, the future of alkylbenzene production looks promising. With continued research and optimization, this groundbreaking technique could revolutionize the detergent industry and pave the way for cleaner and more sustainable chemical synthesis processes.

Leave a Reply