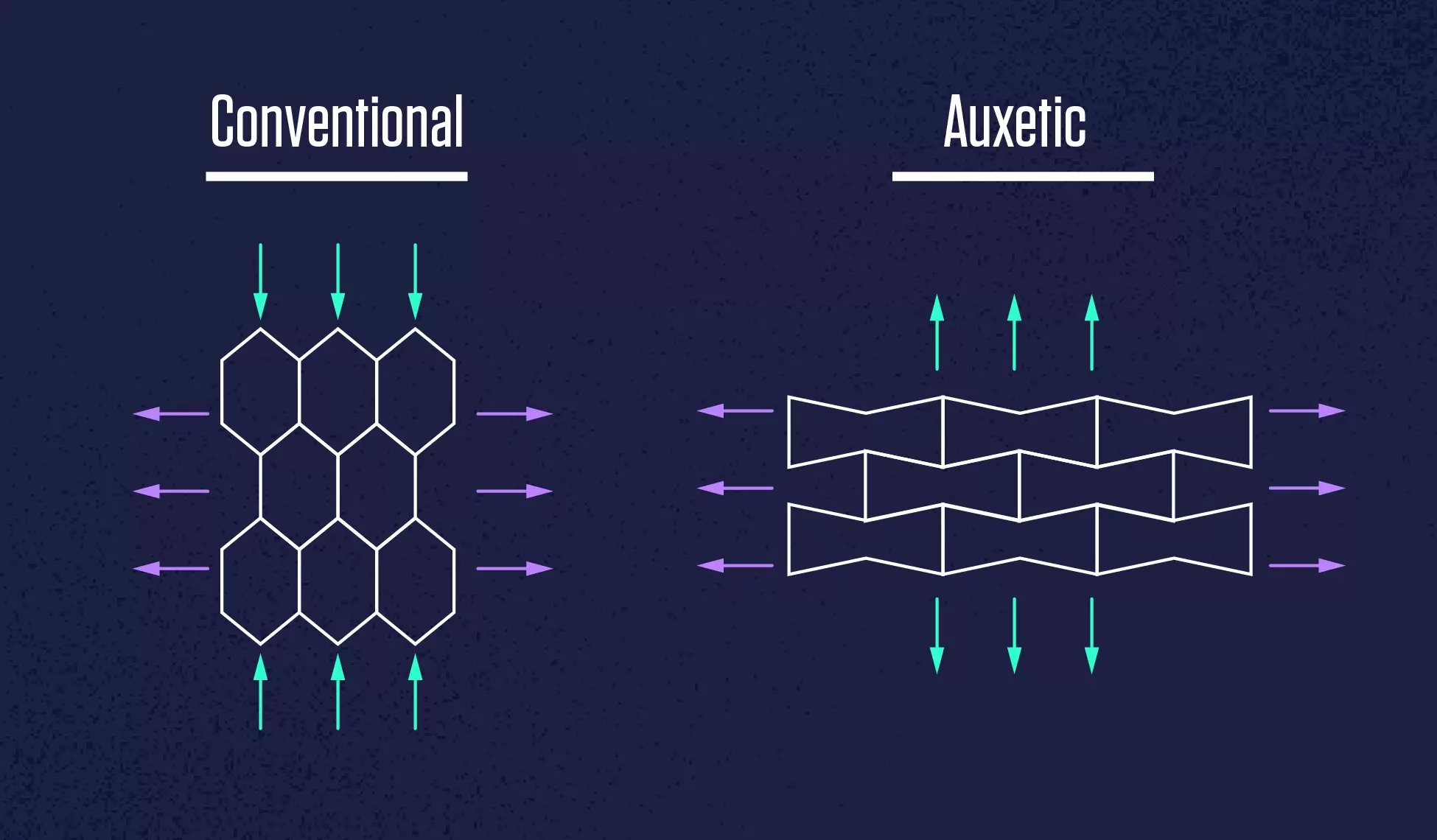

Auxetic materials are a category of materials that defy common sense by becoming wider and fatter when stretched and thinner when compressed. These materials have unique properties that make them perfect for a variety of applications, from sneaker insoles to bomb-resilient buildings. Despite their potential, auxetic products have been slow to enter the market.

Researchers at the National Institute of Standards and Technology (NIST) and the University of Chicago have recently developed a new algorithm to simplify and expedite the design of materials with auxetic properties. This algorithm allows for precise three-dimensional design of auxetics, enabling the optimization of mechanical properties and behavior.

Poisson’s ratio is a key factor in describing the behavior of elastic materials. While most materials have a positive Poisson’s ratio, auxetics have a negative value, causing them to react oppositely to stretching and compression. The unique behavior of auxetics allows for greater resistance to impact, making them ideal for use in buildings, automobiles, sneakers, and clothing.

Auxetic materials have the potential to revolutionize various industries. In buildings and automobiles, they offer increased protection from explosions and collisions. In sneakers, auxetic gel or rubber foam can provide better cushioning for the feet. In clothing, auxetic nylons and fibers can offer improved comfort by distributing pressure more effectively across the body.

The new “inverse design” algorithm developed by NIST and University of Chicago scientists allows users to input their desired value for Poisson’s ratio and generates an optimized structure for the auxetic material. This fine-tuning of the relationship between shape and volume enables the creation of auxetic materials with unique properties not found in nature.

The groundbreaking research conducted by the NIST and University of Chicago scientists demonstrates the potential for auxetic materials to transform various industries. The patented algorithm and methodology, along with its implementation using 3D printing, pave the way for the widespread adoption of auxetics in our everyday lives. By harnessing the power of these innovative materials, we can usher in a new era of advanced technologies and enhanced comfort for individuals worldwide.

Leave a Reply