As technologies for capturing carbon dioxide from the atmosphere continue to improve, finding viable solutions for the utilization of captured carbon becomes a crucial challenge. However, a recent study conducted by Rice University’s lab of materials scientist Pulickel Ajayan has made significant progress in this area. The researchers developed a method that effectively converts carbon dioxide into methane by affixing the carbon to hydrogen atoms. This innovative approach not only produces a valuable fuel and industrial feedstock but also contributes to closing the artificial carbon cycle at meaningful scales. With the development of efficient and affordable catalysts, this breakthrough brings us one step closer to achieving sustainable energy goals.

The method developed by the Ajayan lab relies on electrolysis and catalysts. Electrolysis is a process that uses an electric current to drive a chemical reaction. In this case, carbon dioxide is converted into methane through an eight-step pathway. This pathway, however, presents significant challenges for selective and energy-efficient methane production. The catalysts, which consist of isolated copper atoms grafted onto two-dimensional polymer templates, play a critical role in overcoming these challenges.

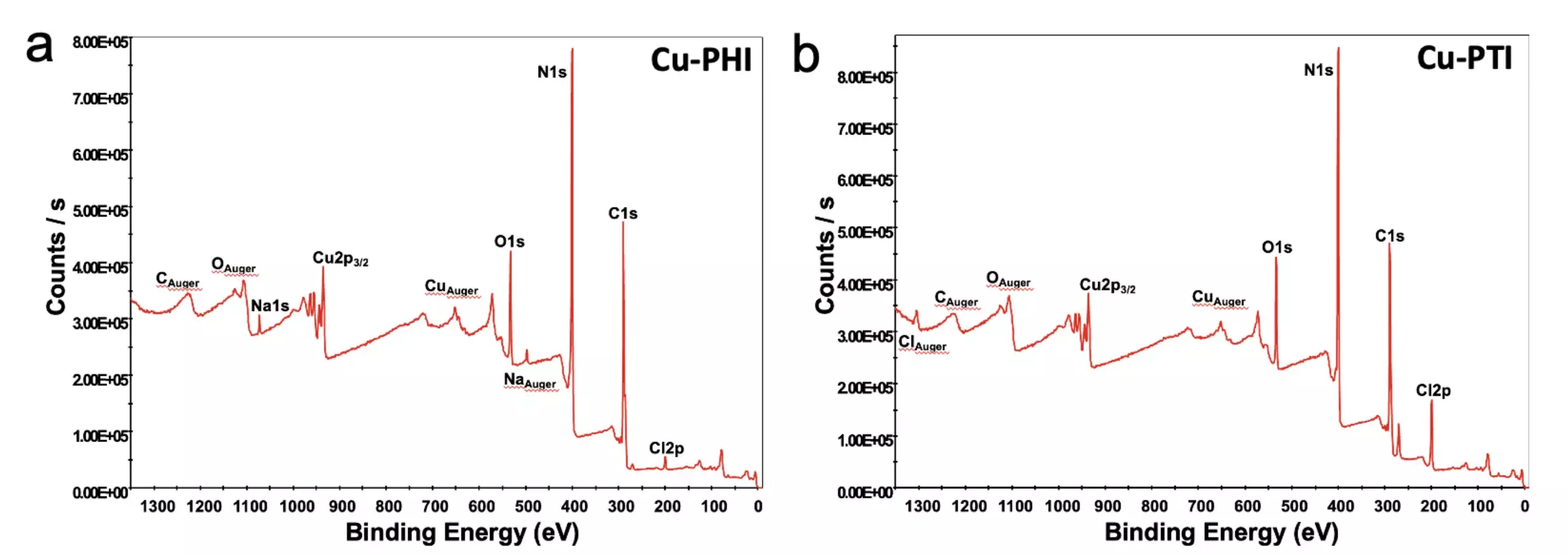

The polymer templates used in the study are made of alternating carbon and nitrogen atoms and feature tiny pores where copper atoms can be placed at varying distances from one another. By assembling at room temperature in water, the catalysts replace the host metal ions in the polymer templates. The modulating distances between the copper atoms have been found to lower the energy required for key reaction steps, effectively speeding up the chemical conversion process. This cooperative action of nearby copper atoms contributes to the high rate of selectivity and efficiency in methane production.

Significance of the Catalysts

According to Soumyabrata Roy, the lead author of the study, the catalysts developed by the researchers have demonstrated remarkable results. They have achieved one of the most rapid and efficient electrolysis-based conversions of carbon dioxide to methane to date. This breakthrough not only provides valuable scientific insights but also pushes the performance level of the conversion process. By addressing the challenges of system-level energy and carbon conversion efficiencies, these catalysts have the potential to catalyze the industrial translation of electrochemical carbon dioxide reduction technology.

The Role of Novel Catalysts

Pulickel Ajayan, the chair of the Department of Materials Science and NanoEngineering, highlights the significance of developing novel catalysts in addressing the energy and sustainability challenges faced by the industry. The use of single-atom dispersed catalysts presents an exciting approach in achieving these goals. The advancements made by the Ajayan lab in this area not only contribute directly to sustainable energy but also pave the way for further developments in the field.

The breakthrough achieved by Rice University’s Ajayan lab in converting carbon dioxide into methane brings us closer to finding a solution for the utilization of captured carbon. By utilizing electrolysis and novel catalysts, this method offers a pathway to sustainable energy by producing a valuable fuel and industrial feedstock. The development of efficient and affordable catalysts plays a crucial role in advancing the conversion process and addressing energy and sustainability challenges on a broader scale. As we continue to make progress in this field, the translation of electrochemical carbon dioxide reduction technology into industrial applications becomes increasingly promising.

Leave a Reply