The fashion industry is one of the largest polluters globally, contributing to immense environmental degradation through fast fashion and textile waste. An innovative research team at Cornell University, led by Professor Juan Hinestroza, is pioneering a technique that could potentially revolutionize how we think about waterproof coatings for clothing. By transforming discarded textiles into a superhydrophobic coating, the researchers aim not only to reduce reliance on harmful chemical processes but also to promote a more sustainable approach to clothing production. This breakthrough could have significant implications for both the environment and human health, as traditional waterproofing methods rely on toxic substances.

Hinestroza and his team have successfully developed a low-temperature synthesis process for these waterproof coatings, focusing on repurposing discarded polyester and spandex textiles. The significance of this research lies in its potential to tackle two pressing issues: textile waste and the environmental hazards posed by conventional waterproofing chemicals. The team asserts that by creating coatings from what would otherwise be landfill waste, they are not only contributing to the reduction of textile waste but also providing a safer alternative for consumers.

The underlying process involves a chemical breakdown of unwanted polyester clothing, yielding a versatile metal-organic framework (MOF) that acts as the basis for the waterproof coating. This method relies on environmentally friendly solvents such as water and ethanol, allowing for a more sustainable production process. Consequently, this approach eschews fierce separation and purification methods typically employed in the textile industry, which are energy-intensive and contribute to environmental stress.

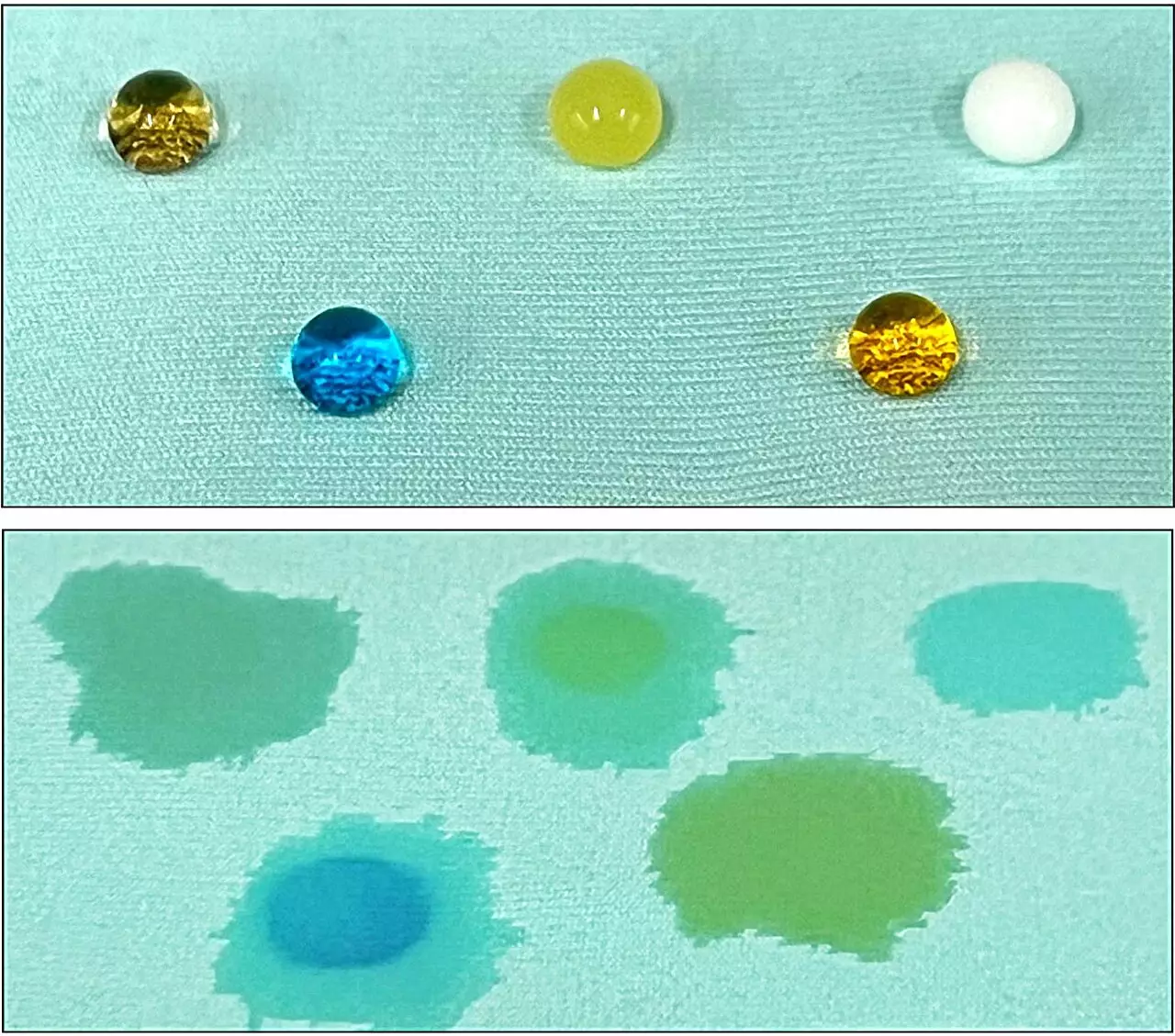

The research led by doctoral student Yelin Ko, along with Professor Tamer Uyar, has demonstrated how discarded textiles, when subjected to an alkaline depolymerization process, can be converted into a substance rich in disodium terephthalate. This component serves as a key linker in synthesizing the UiO-66 MOF. Upon integration into the coating, the material exhibited remarkable water-repellent properties, proving effective even after repeated washing and abrasion tests.

Moreover, the study highlighted the unique modifications brought about by the spandex fragments. Instead of the MOF remaining hydrophilic, the presence of spandex altered its chemical behavior, resulting in the desired superhydrophobic characteristic. This innovative synthesis not only propels the researchers’ work into cutting-edge territory but also addresses the persistent problem of textile waste in a sustainable manner.

Hinestroza emphasizes the broader implications of their findings in the context of reducing harmful chemical usage in textile manufacturing. Current coatings, often referred to as “forever chemicals,” are notorious for their persistence in the environment and have been linked to serious health risks. The Cornell team’s work opens the door to alternatives that can provide similar functional finishes—such as water resistance and self-cleaning properties—without the ecological footprint.

The concept of “upcycling,” as discussed by Hinestroza, is integral to this research. It addresses the cyclical nature of fast fashion: consumer habits directly influence production practices. By creating value from discarded textiles, this research highlights a path toward a more conscious approach to consumption. It serves as a call to action for consumers to reflect on their purchasing decisions and their ramifications for the environment.

This groundbreaking study is more than just a technical achievement; it represents a paradigm shift in the textile industry. By repurposing waste into functional, environmentally friendly products, Hinestroza and his team are setting a precedent for future innovations in sustainable fashion. Their work underlines the necessity of balancing consumerism with ecological responsibility, pushing the narrative toward a future where fashion is both stylish and sustainable. The shift from traditional methods to innovative solutions characterized by upcycling and low-impact processes could one day redefine how we produce and consume textiles, leading to a healthier planet for future generations.

Leave a Reply