Plastic has become an integral part of modern society, but its impact on the environment is undeniable. The majority of plastics are derived from non-renewable resources, and their persistence in nature makes them a major source of pollution. Engineers and researchers have been exploring alternatives to conventional plastics, with the hope of finding a more sustainable solution. One such alternative is polylactic acid, a bioplastic that can be produced from plants. However, polylactic acid has its own set of challenges, including brittleness and poor degradation. In an effort to address these issues, bioengineers at Kobe University have developed a groundbreaking solution involving engineered bacteria.

The team at Kobe University, in collaboration with Kaneka Corporation, set out to create a plastic modifier called LAHB that could enhance the properties of polylactic acid. By mixing polylactic acid with LAHB, the researchers aimed to create a material that is more processable, fracture-resistant, and highly biodegradable, even in seawater. To achieve this, they needed to engineer a strain of bacteria capable of producing LAHB. This involved manipulating the organism’s genome by introducing new genes and removing interfering ones.

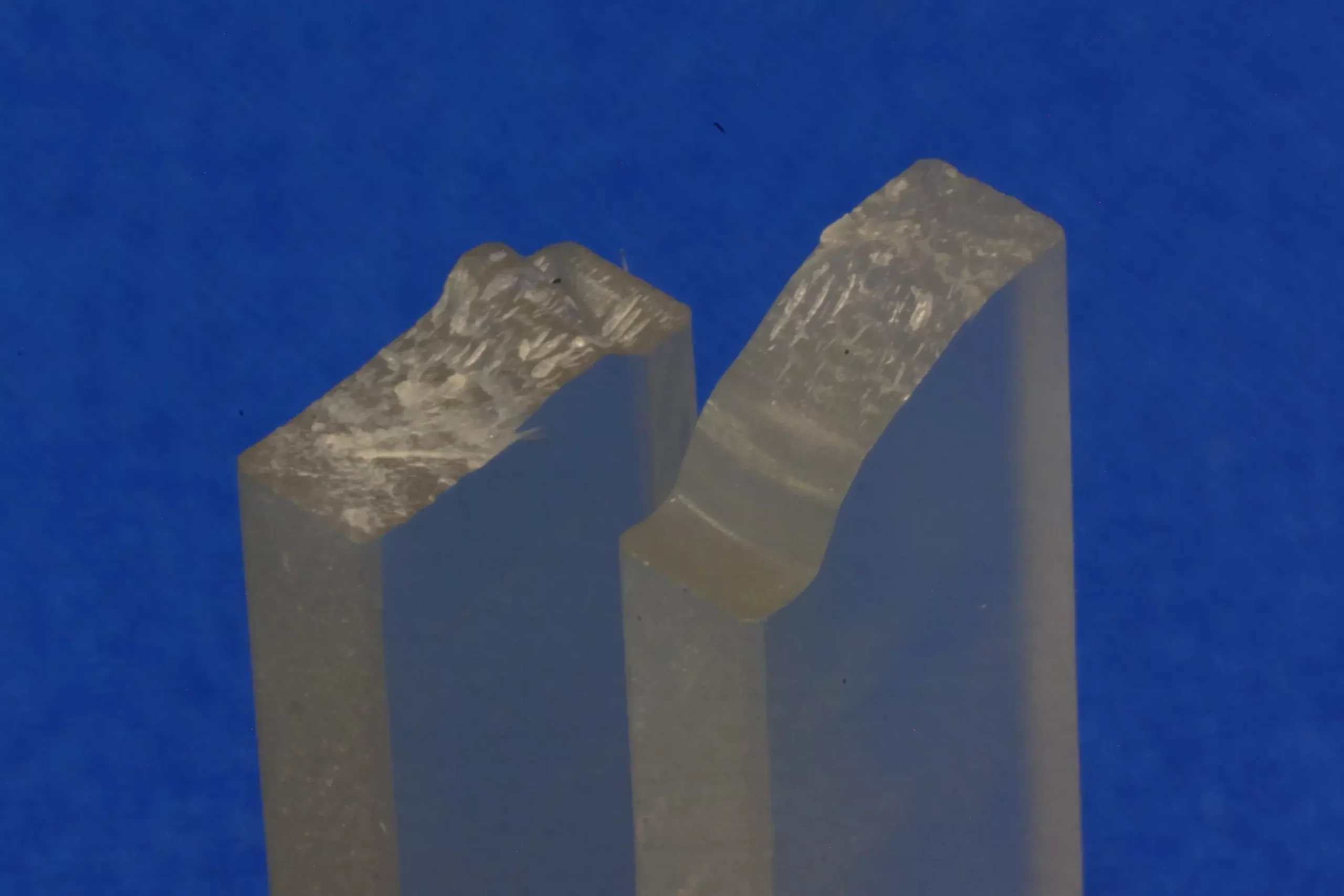

In their research published in the journal ACS Sustainable Chemistry & Engineering, the team at Kobe University reported their success in creating a bacterial “plastic factory” that could produce high amounts of LAHB chains using glucose as a feedstock. By modifying the genome of the bacteria, they were able to control the length of the LAHB chain, resulting in what they termed “ultra-high molecular weight LAHB.” This breakthrough allowed them to produce a highly transparent plastic that exhibited the desired properties of moldability, shock resistance, and biodegradability.

The combination of polylactic acid and LAHB has the potential to revolutionize the plastic industry by providing a sustainable and environmentally friendly alternative to conventional plastics. The researchers believe that this modified material can address the conflicting needs of physical robustness and biodegradability, making it a promising solution for a greener future. Furthermore, the engineered bacteria used in this process have the ability to utilize CO2 as a raw material, opening up the possibility of synthesizing plastics directly from greenhouse gases.

The development of LAHB by Kobe University bioengineers represents a significant advancement in the quest for sustainable plastics. By harnessing the power of engineered bacteria, researchers have been able to create a material that offers the advantages of conventional plastics without the environmental drawbacks. The potential of this technology to transform the plastic industry and contribute to a more sustainable future is a testament to the ingenuity and creativity of the scientific community.

Leave a Reply