The field of 3D printing has seen significant advancements in recent years, with researchers constantly striving to improve the functionality and capabilities of the materials used in the process. One such breakthrough comes from scientists and engineers at the University of Nottingham, who have developed a new coating for plastic particles that are commonly used in 3D printing. This innovative technology not only enhances the functionality of the materials but also opens up new possibilities for commercial applications in various industries.

The researchers at the University of Nottingham’s School of Chemistry and Faculty of Engineering have utilized supercritical carbon dioxide to create an efficient, effective, and clean process for coating PA-12 polymer particles used in 3D printing. This new coating technology has shown promising results in enhancing the properties of the printed objects, including adding color and anti-mold and anti-fungal properties to the printing process. The findings of this groundbreaking research have been published in the prestigious journal Nature Communications.

Enhancing Material Capabilities

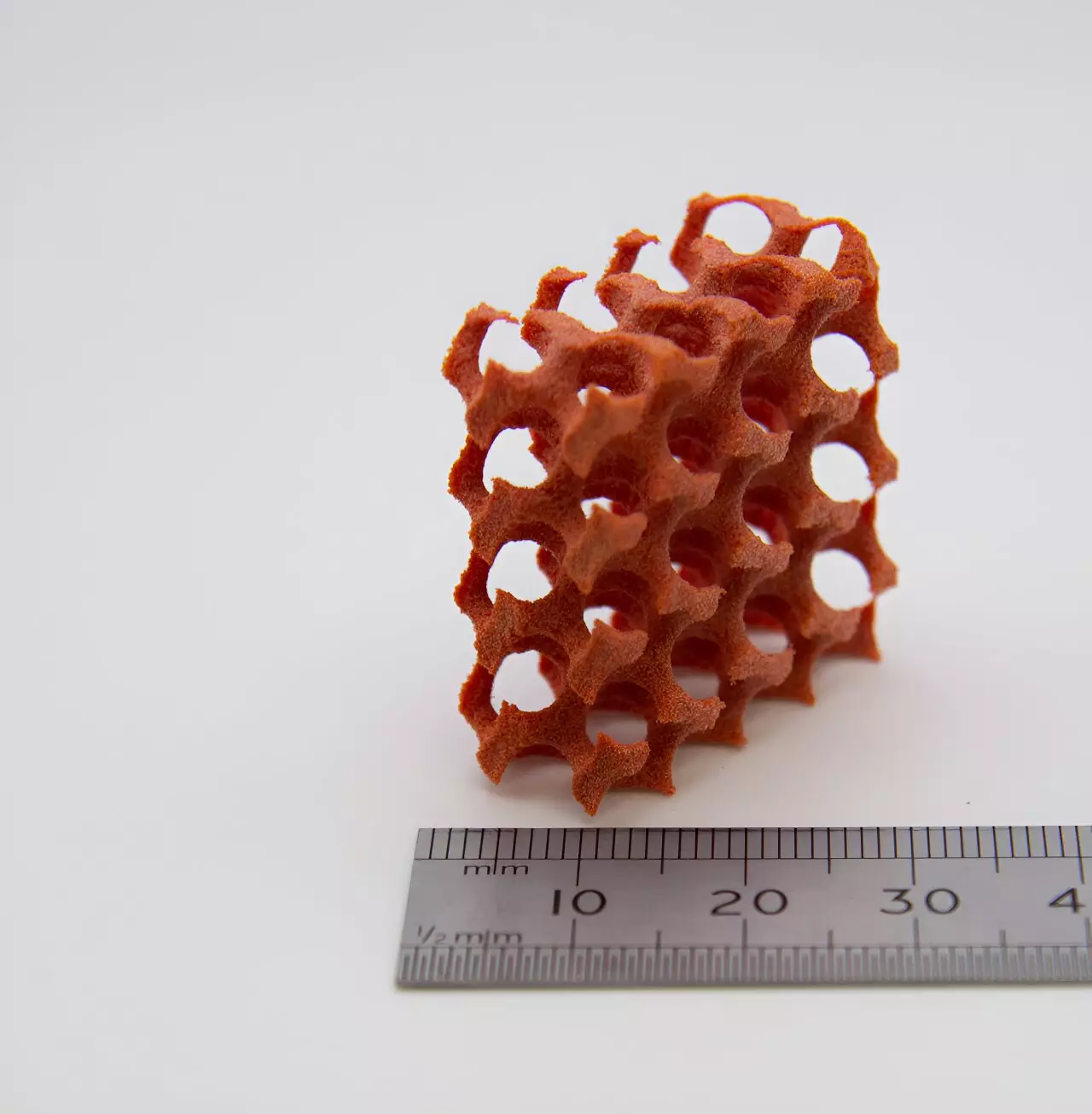

One of the most common 3D printing techniques in commercial use is powder bed fusion or laser sintering. This process involves laying down a layer of polymer powder, which is then melted layer-by-layer using a laser guided by a computer-generated design. The addition of the new coatings not only improves the aesthetic appeal of the printed objects by adding color but also imparts important functional properties such as anti-mold and anti-fungal characteristics. This development expands the range of material capabilities available for 3D printing without compromising the processability of the materials.

Polyamide-12 (PA12) is a widely used plastic in the 3D printing industry, particularly in the automotive and aerospace sectors, due to its strength and versatility. However, traditional PA-12 printed objects are limited in their use in moist environments due to the growth of mold and fungi. The new shell coating developed by the researchers offers a solution to this limitation by providing a protective barrier that prevents the growth of mold and fungi. This breakthrough opens up new possibilities for using 3D printed objects in a variety of new applications and industries.

The 3D printing industry faces several challenges related to the limitations of the functionality of the polymers used in the process. By introducing a simple yet effective approach to adding functionality through coating the particles, the researchers at the University of Nottingham have addressed some of these challenges. The newly designed colored shell polymer matches the mechanical and thermal properties of the printing polymer, ensuring compatibility with existing commercially deployed machines. This innovation demonstrates the potential for enhancing the capabilities of 3D printing materials while maintaining ease of use and versatility.

The development of a new coating technology for plastic particles used in 3D printing represents a significant advancement in the field. The innovative approach taken by the researchers at the University of Nottingham has the potential to revolutionize the 3D printing industry by expanding the range of material capabilities and introducing new functional properties to printed objects. With further research and development, this new coating technology could pave the way for the creation of bespoke, unique, and multifunctional 3D printed objects that can be used in a wide range of commercial applications.

Leave a Reply