In the realm of energy storage technologies, sodium-ion batteries are emerging as a compelling alternative to the current lithium-ion batteries. These innovative batteries utilize sodium (Na), an element that is more abundant and easier to refine than lithium (Li). The shift from lithium to sodium presents several advantages, such as enhanced electrochemical stability, which permits more efficient fast charging and discharging. These features are particularly valuable in applications like electric vehicles (EVs), where reliability and performance under various conditions are essential. However, despite their advantages, sodium-ion batteries have not yet achieved widespread commercial adoption due to inherent challenges associated with their production and performance metrics.

One of the most pressing challenges facing the development of sodium-ion batteries is their energy density. While sodium is plentiful, the storage solutions available for these ions have not yet matched the energy densities achieved by their lithium counterparts. Moreover, the lifespan of sodium-ion batteries tends to be shorter, mainly due to the complex processes involved in manufacturing the necessary components. The larger size of sodium ions requires the use of hard carbon for anodes, which presents its own set of challenges. Hard carbon is synthesized rather than naturally occurring, demanding intricate manufacturing processes that involve high temperatures—often exceeding 1,000°C—and lengthy carbonization.

Additionally, the carbonization process typically faces criticism for its economic and environmental impact, limiting the feasibility of sodium-ion batteries in the market. This situation has stifled innovation and hindered progress, making it imperative to find new methodologies to streamline production and enhance the performance of sodium-ion batteries.

Recent research spearheaded by Dr. Daeho Kim and Dr. Jong Hwan Park of the Korea Electrotechnology Research Institute (KERI) offers a beacon of hope to the sodium-ion battery landscape. Their groundbreaking work has introduced a novel process that utilizes microwave induction heating to prepare hard carbon anodes in a remarkably efficient 30 seconds. By harnessing a technique commonly used in microwave ovens, the researchers have the potential to revolutionize the manufacturing process for sodium-ion batteries.

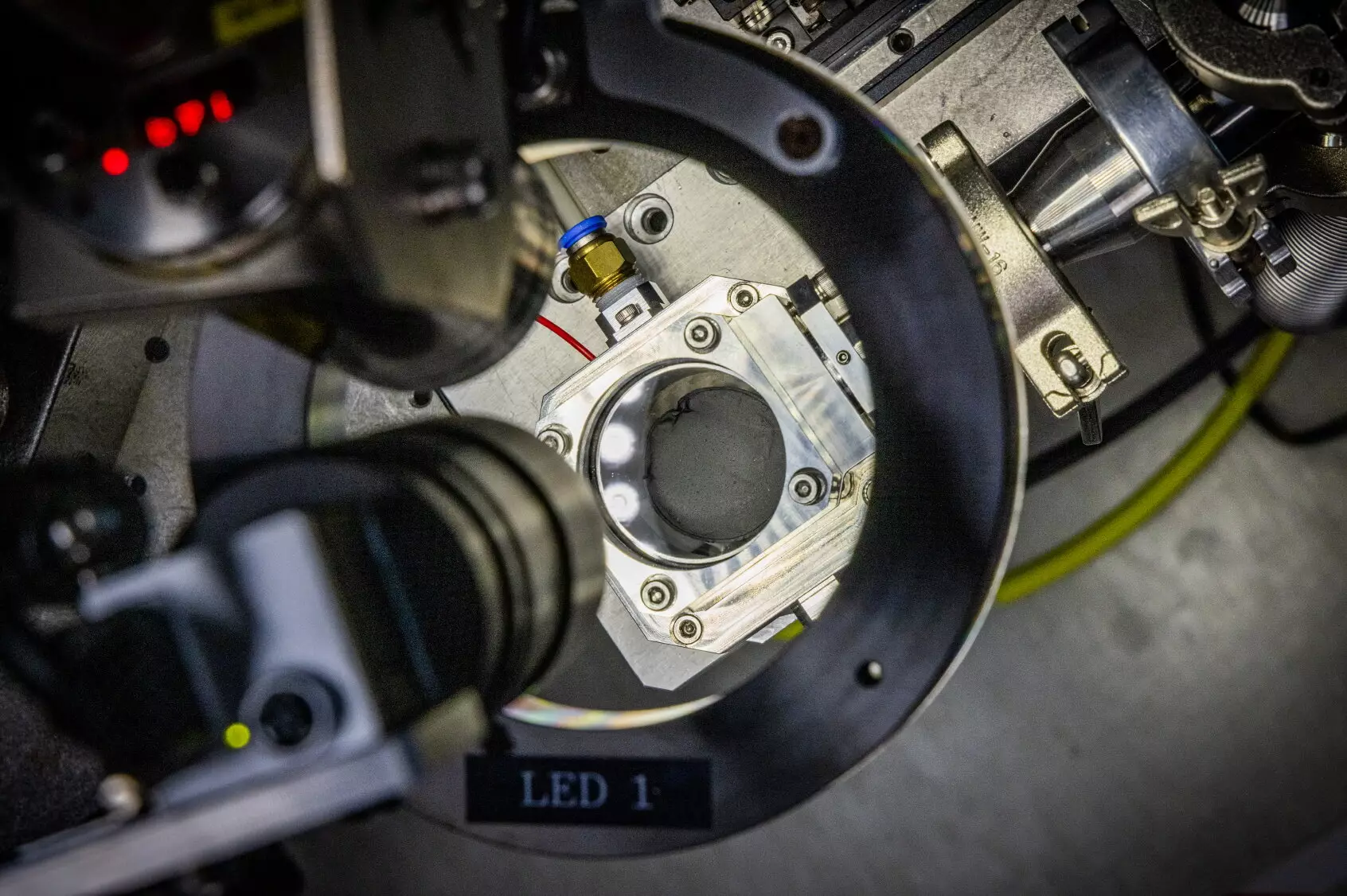

This microwave technology can selectively heat films composed of polymers and a small quantity of conductive carbon nanotubes, reaching temperatures beyond 1,400°C in mere seconds. Such rapid heating not only reduces production times significantly but also enhances energy efficiency—a critical factor for commercial viability. KERI’s expertise in uniform heat treatment of various materials, including metals, has equipped the research team with the tools necessary to make this technological leap.

Central to the success of this microwave induction heating process is the team’s “multiphysics simulation” technique, which provides insight into the intricate interactions occurring when electromagnetic fields are applied to nanomaterials. This simulation capability has enabled the researchers to gain a better understanding of the behavior of materials under microwave treatment, paving the way for the efficient synthesis of hard carbon anodes tailored for sodium-ion batteries.

The results of this research have garnered significant attention in the scientific community, culminating in publication in the Chemical Engineering Journal. The collaboration between student researchers Geongbeom Ryoo and Jiwon Shin alongside the KERI team illustrates the meaningful impact of academia-research partnerships in producing innovative solutions.

Despite the promising results, the journey does not end with the initial breakthrough. The KERI team aims to enhance the performance of their anode materials further and develop processes for continuous mass production of hard carbon films. With the ever-growing demand for sustainable energy solutions, the commercial appeal of sodium-ion batteries could be on the brink of transformation. The researchers are also exploring applications of their microwave induction heating technology beyond sodium-ion batteries, with potential uses in all-solid-state batteries and other energy storage paradigms that demand high-temperature processes.

KERI has initiated the patent application process for this innovative technology, indicating that they are poised for partnerships with industry players interested in energy storage solutions. As the global market increasingly prioritizes alternative, safer, and more efficient battery technologies, the work of Dr. Kim, Dr. Park, and their team may represent a pivotal moment in the future of energy storage. Their advances not only have the potential to commercialize sodium-ion batteries but also to contribute to a broader revolution in how we produce and utilize energy storage technologies.

Leave a Reply