The increasing global demand for renewable energy technologies, particularly electric vehicles (EVs) and wind turbines, has propelled the significance of rare-earth elements (REEs) into the spotlight. Among these elements, neodymium (Nd) and dysprosium (Dy) are critical components for manufacturing high-performance magnets that power many green technologies. However, the extraction and recycling of these elements from end-of-life products pose significant challenges, prompting urgent research into sustainable solutions. A recent study led by Kyoto University’s research team, under the guidance of Professor Toshiyuki Nohira, introduces an innovative technique that not only promises efficiency but also aligns with global sustainability goals: the selectively extracting, evaporating, and electrolysis (SEEE) method.

Traditionally, recycling rare-earth metals has involved complex and energy-intensive processes that contribute to significant environmental degradation. These methods predominantly rely on hydrometallurgical approaches, which involve using hazardous chemicals and generating substantial waste. Given the environmental costs associated with mining and refining, a robust solution for recycling these elements has become imperative. The SEEE process stands out as a potential game-changer due to its environmentally friendly nature and high efficiency, providing a much-needed alternative to conventional methods.

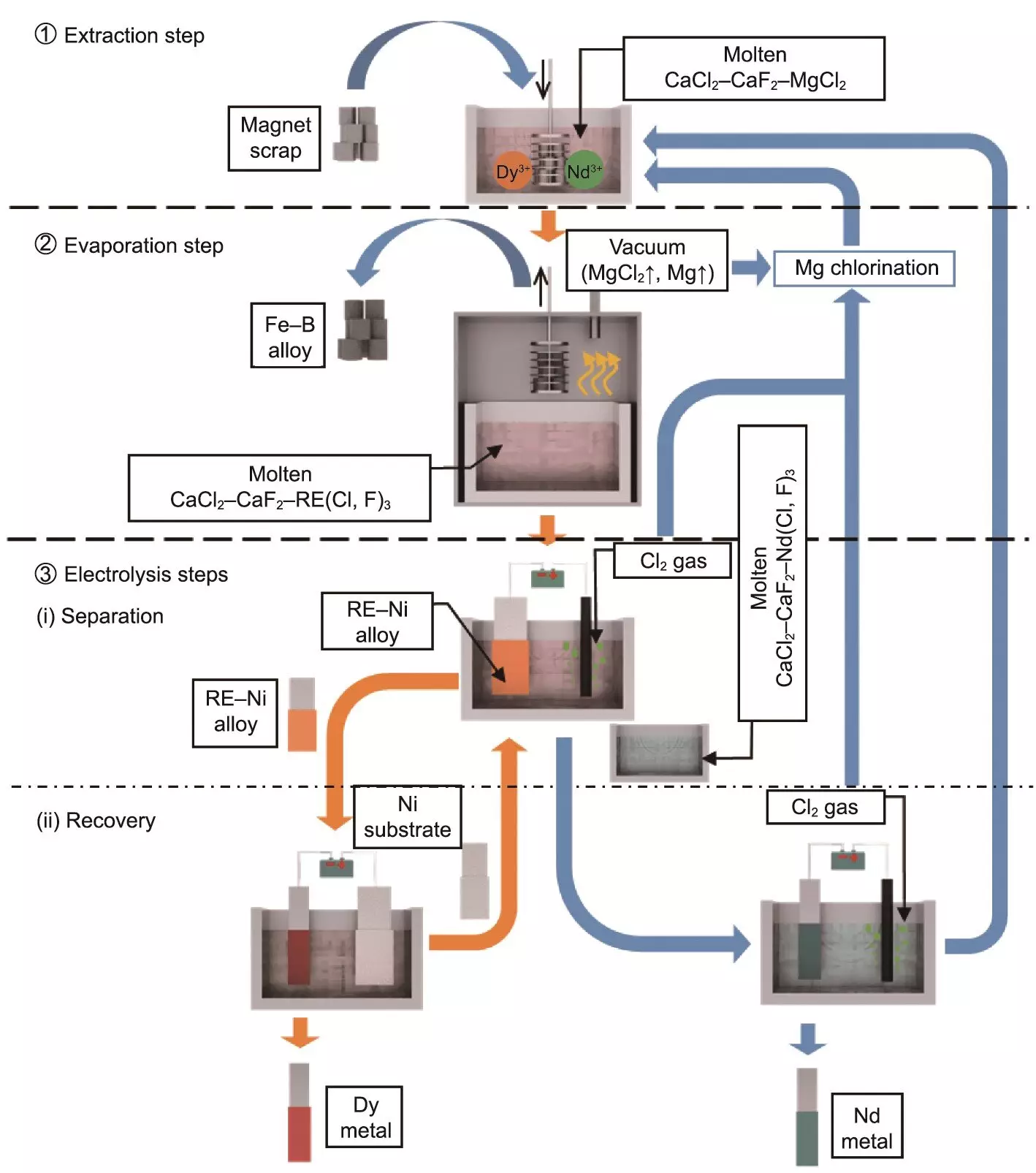

The SEEE process comprises three essential stages that meticulously focus on the extraction and recycling of REEs from end-of-life magnets.

1. **Selective Extraction**: The initial phase employs a molten salt mixture, specifically designed using calcium chloride (CaCl2) and magnesium chloride (MgCl2), to extract REEs from scrap magnets. Incorporating calcium fluoride (CaF2) enhances the process by minimizing evaporation losses while optimizing extraction efficiency.

2. **Selective Evaporation**: Following extraction, the process removes residual agents and byproducts through selective evaporation, thereby concentrating the valuable REEs for the subsequent step.

3. **Selective Electrolysis**: The final stage utilizes electrochemical methods to separate the extracted elements based on their distinct formation potentials. This method results in the recovery of high-purity neodymium and dysprosium, crucial for their application in eco-friendly technologies.

The impressive results from this study reveal recovery rates of 96% for neodymium and 91% for dysprosium, with the purity levels exceeding 90%. These metrics underscore a significant enhancement over traditional recycling methods and indicate substantiated progress in material recovery.

As the demand for clean energy technologies surges, ensuring a consistent and sustainable supply of REEs is crucial. The SEEE process not only fulfills this need but also mitigates the reliance on environmentally damaging mining operations. Successful implementation of this innovative recycling technique could lead to a more stable supply chain for critical resources, promoting economic sustainability and environmental health.

Furthermore, the SEEE process has the potential to transcend its initial application by adapting its principles to other industries. For instance, researchers speculate its feasibility in nuclear fuel reprocessing, thereby expanding its implications into other critical sectors. Such versatility highlights the process’s potential in contributing to broader efforts in sustainable resource management.

While the SEEE process showcases promising capabilities, transitioning from laboratory results to industrial applications will require further technical scrutiny and development. Continued research is essential to optimize the process for scalability and ensure its compatibility with existing recycling systems. However, the significance of this study lies not just in the process itself but in the broader message regarding the urgency of innovating sustainable practices in response to rising environmental concerns.

As we face an escalating need for greener technologies, the SEEE process offers a beacon of hope in the arena of rare-earth element recycling. The study emphasizes the importance of continuous innovation and research in shaping a more sustainable future. The advancement of recycling technologies like SEEE not only aims at preserving valuable resources but also aligns with global efforts towards achieving carbon neutrality. In navigating the complexities of environmental sustainability, orchestrated efforts in advanced research will inevitably carve pathways toward more responsible and efficient resource management strategies.

Leave a Reply