Polyurethane foam is a versatile material used in a wide range of products such as mattresses, insulation, shoes, cars, and more. However, despite its numerous applications, polyurethane foam poses a significant environmental and climate burden. The majority of products made from polyurethane foam end up being incinerated or dumped in landfills, leading to environmental pollution. Additionally, the main components of polyurethane foam are derived from fossil oil, making it a resource-intensive material. With the global market for polyurethane reaching millions of tons, it is crucial to find sustainable ways to recycle and reuse this material.

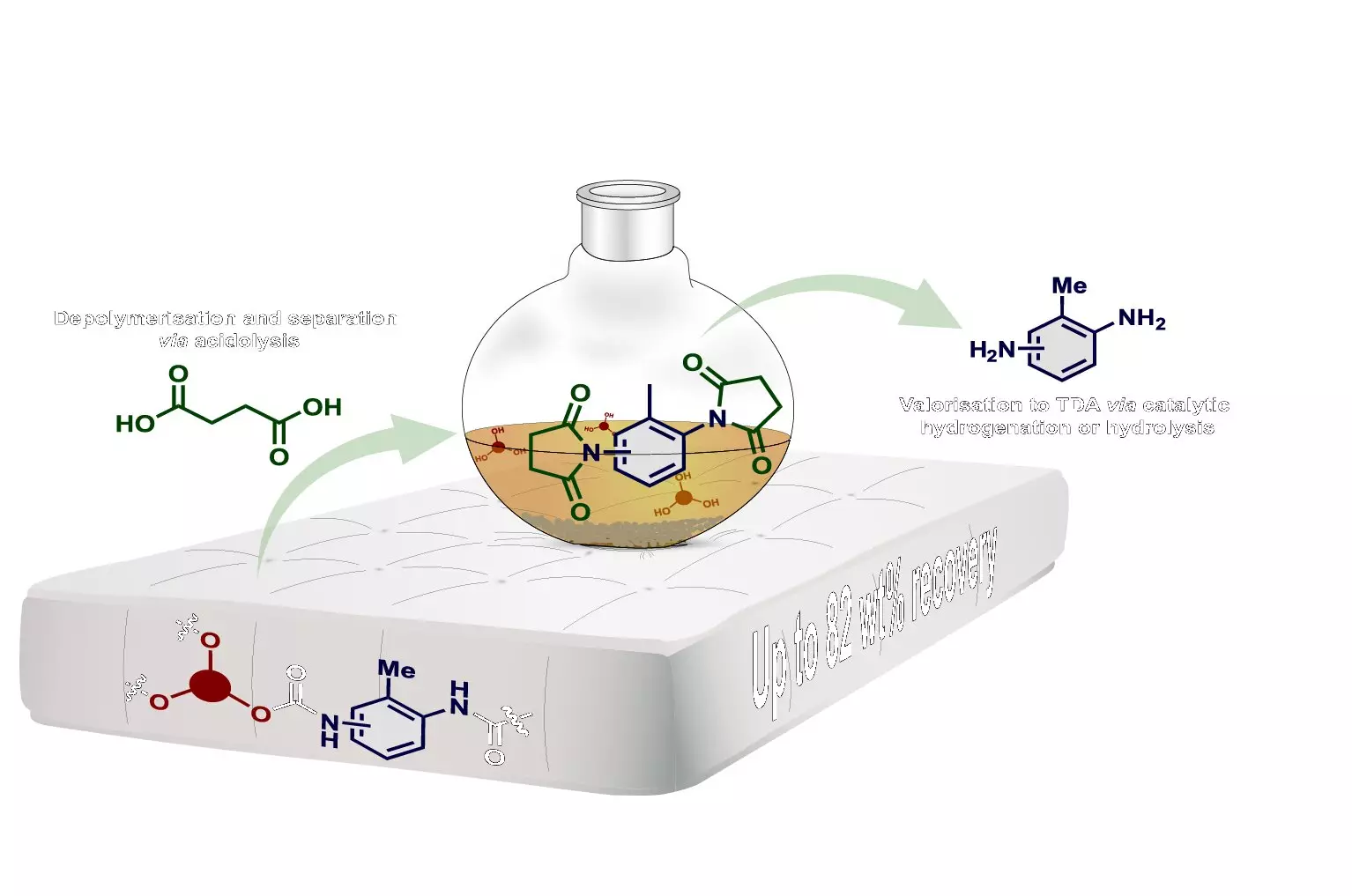

Researchers at Aarhus University have developed an innovative method to recycle polyurethane foam more efficiently. Unlike traditional recycling processes that result in a mixture of materials, the new method allows for the separation of polyol and isocyanate, the main components of polyurethane foam. By using a combination of acidolysis and hydrolysis, the researchers are able to break down polyurethane foam into its original components in one step.

The research team at Aarhus University found that by heating flexible polyurethane foam to 220°C with succinic acid in a reactor, they could separate polyol and isocyanate effectively. The polyols obtained from this process are of high quality, comparable to virgin polyol, making them suitable for use in new polyurethane products. The solid residues from the process can also be transformed into diamines, which are used in the production of isocyanates and polyurethane.

One of the key advantages of this new recycling method is its scalability. The researchers believe that this method can be easily implemented in factories that produce polyurethane foam products, allowing them to recycle waste materials more efficiently. However, challenges remain when it comes to handling polyurethane waste from consumers, as each manufacturer uses unique formulae for their products. Waste sorting, logistics, and sorting polyurethane into different types are some of the challenges that need to be addressed for a successful transition to a circular economy.

The Future of Polyurethane Recycling

While the new method shows promise for recycling flexible polyurethane foam used in mattresses, the researchers are also exploring its applicability to other types of polyurethane materials. From regenerated foam to rigid foam used in insulation materials, the researchers are working towards creating a circular economy for polyurethane. By testing the new technology on various polyurethane materials and exploring the reuse of dicarboxylic acid in the process, the researchers aim to demonstrate the potential of their method to revolutionize polyurethane foam recycling.

The breakthrough method developed by the researchers at Aarhus University offers a promising solution to the environmental challenges posed by polyurethane foam. By efficiently recycling polyurethane foam into its original components, the method paves the way for a more sustainable and circular economy in the polyurethane industry. Through further research and development, the researchers hope to create a viable and cost-effective solution for recycling polyurethane waste and reducing the environmental impact of this versatile material.

Leave a Reply