Piezoelectric materials are pivotal in various modern technologies, particularly in ultrasound and sonar applications. These materials possess the unique ability to convert mechanical stress into electrical energy, and vice versa, through a phenomenon called piezoelectricity. This property is particularly exploited in devices like ultrasound transducers, which generate sound waves for medical imaging and sonar systems for underwater exploration. However, maintaining the efficiency and effectiveness of these piezoelectric materials presents significant challenges, particularly under conditions of extreme temperature and pressure.

A crucial issue concerning piezoelectric materials is their susceptibility to environmental conditions that may lead to a loss of their desirable properties. When exposed to even moderate temperatures—like those as low as 70°C—the internal dipoles within these materials can lose their alignment. This misalignment compromises their ability to generate the targeted ultrasound waves, resulting in suboptimal device performance. Historically, rectifying this degradation required complicated and costly disassembly processes, wherein the affected piezoelectric components had to be heated to temperatures exceeding 300°C to restore their functionality.

The implications of this degradation are vast. Transducers used in critical applications may lose functionality, leading to increased costs in repair or replacement. Moreover, the heat generated by the devices during normal operation could further exacerbate the problem, resulting in a continuous cycle of damage. Recognizing the urgent need for a reliable solution, researchers have endeavored to develop methods that could alleviate these issues without the need for laborious disassembly.

Recent advancements by a team of researchers at North Carolina State University have marked a significant breakthrough in the field of piezoelectric materials. Their study—entitled “Electrical De-poling and Re-poling of Relaxor-PbTiO3 Piezoelectric Single Crystals without Heat Treatment,” published in *Nature Communications*—highlights a novel technique that allows for the re-poling of piezoelectric materials at room temperature.

This new method circumvents the traditionally required high-temperature processes, significantly simplifying the repair and maintenance of ultrasound devices. The ability to realign dipoles without disassembling devices not only enhances operational efficiency but also extends the lifespan of the materials used, alleviating concerns about the waste associated with discarded components.

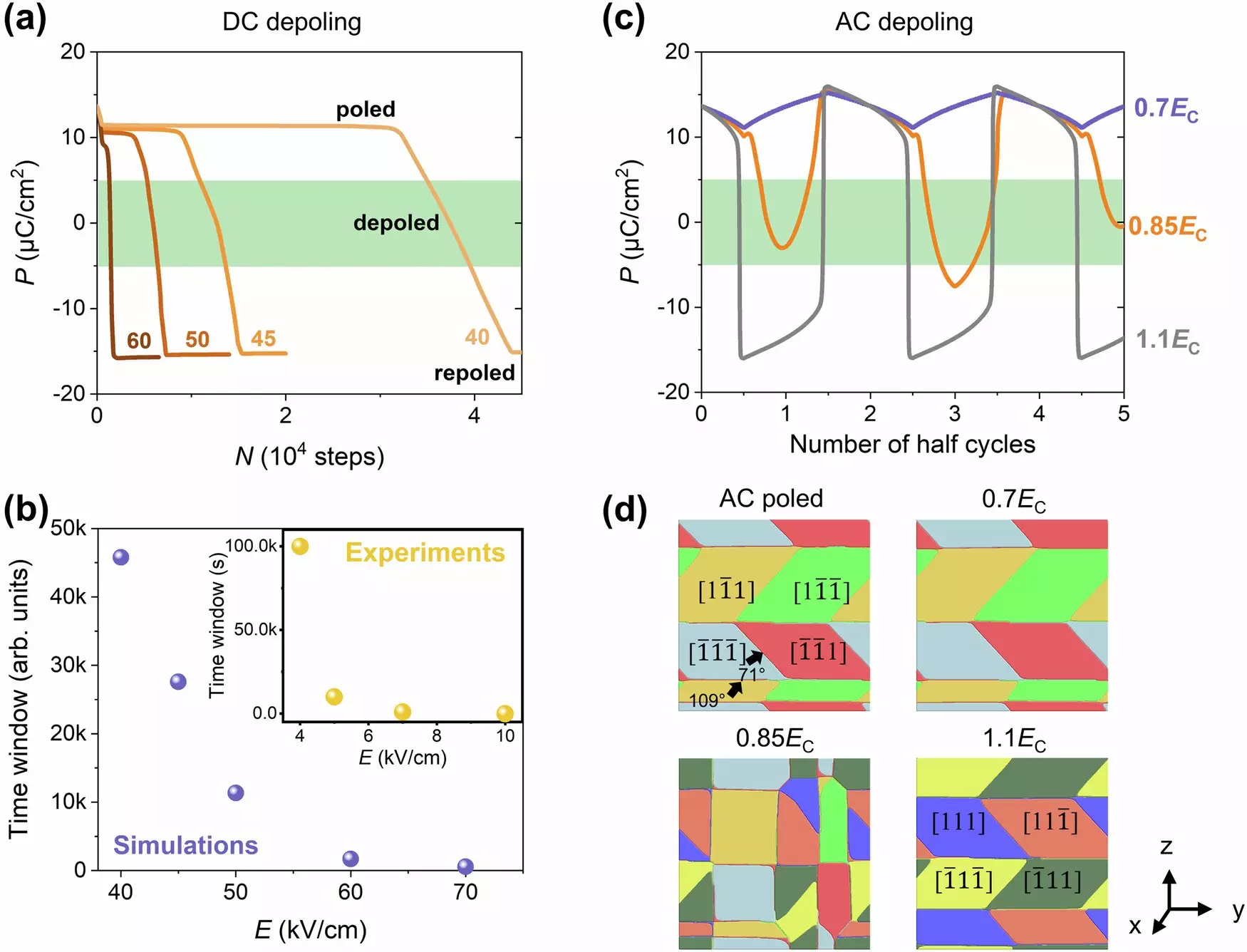

To appreciate the implications of this development, it is essential to examine how dipoles within piezoelectric materials are aligned. The traditional method involves applying a direct current (DC) electric field that aligns the dipoles uniformly in one direction. However, DC methods present limitations, particularly in the context of re-poling; specifically, they are not effective at de-poling the materials.

Alternatively, the researchers discovered that applying an alternating current (AC) electric field offers a solution to this limitation. The oscillation induced by an AC field allows for better manipulation of dipole orientation. When the AC field is removed, the previously misaligned dipoles can lock into a newly established orientation. Remarkably, it was found that materials poled with an AC field could be entirely de-poled and re-poled using the same AC technique at room temperature.

The potential applications of this discovery are profound. Firstly, it opens avenues to optimize manufacturing processes for ultrasound devices, allowing for a broader selection of compatible materials without risking misalignment of the piezoelectric components. This flexibility could lead to enhanced device performance, making ultrasound applications more effective in medical diagnostics, industrial testing, and various sonar technologies.

Moreover, the practical nature of this room temperature technique may lead to cost reductions in maintaining and repairing devices. Given the high expense often associated with quality piezoelectric materials, this innovation allows for their reuse and recycling, aligning with sustainability goals in technology development.

The recent research into the poling and depoling of piezoelectric materials at room temperature marks a significant milestone in material science and engineering. The ability to maintain and restore the critical properties of these materials without extreme heat treatment revolutionizes the approach to ultrasound and sonar technologies. As these methods are refined and adopted, they have the potential to improve the reliability and performance of essential devices across various fields, signaling a new era of innovation driven by thoughtful scientific exploration.

Leave a Reply