As digital technology continues to advance, the world faces a mounting challenge: electronic waste (e-waste). This waste, which encompasses discarded gadgets and components, is not only an environmental hazard but also a treasure trove of valuable metals. With the increasing reliance on electronics, the demand for efficient metal recovery methods has never been greater. A groundbreaking study from Rice University, led by notable chemist James Tour, provides a promising solution that aims to tackle both e-waste and its associated environmental consequences.

Innovative Techniques in Metal Recovery

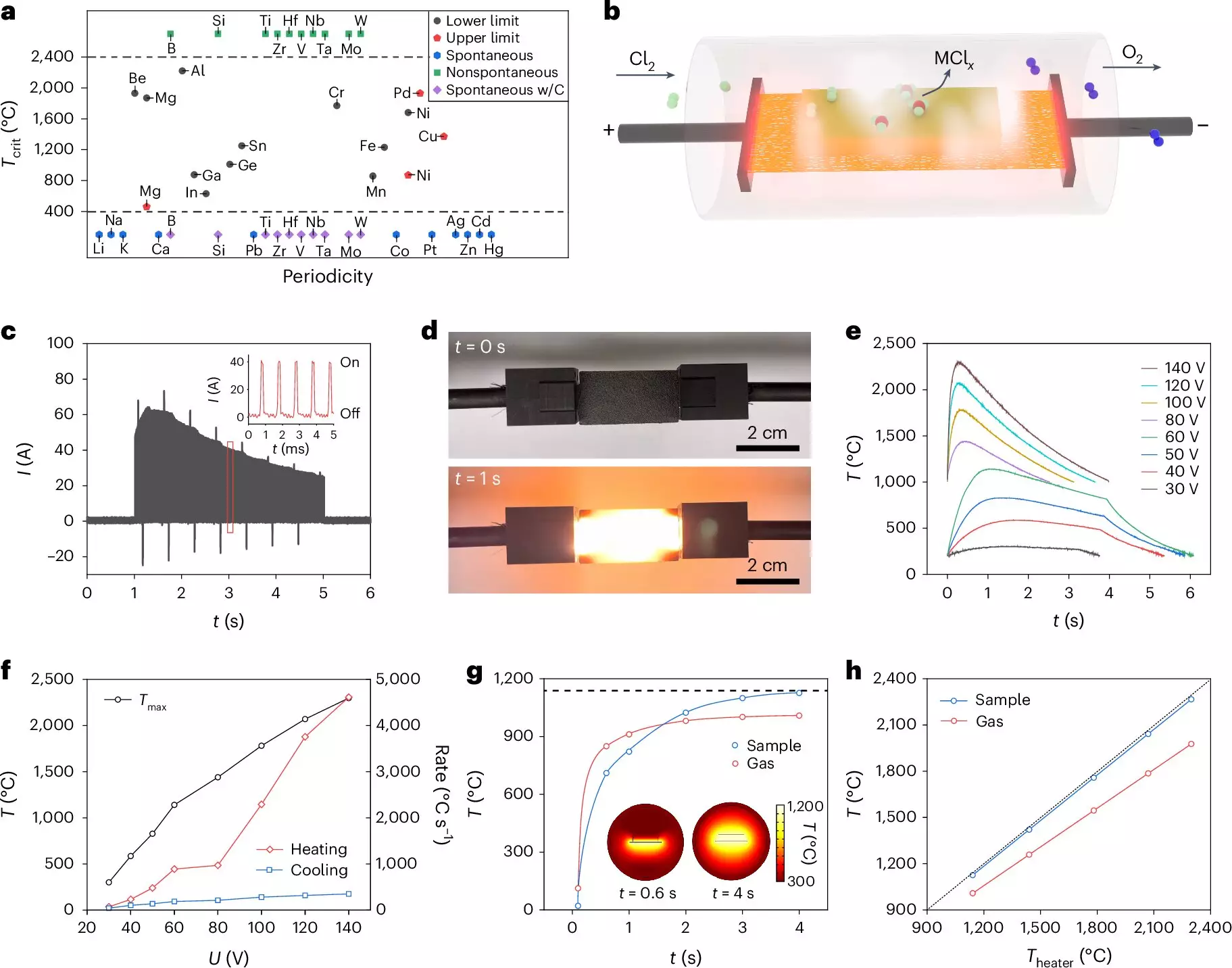

The research team introduced a pioneering approach to recycling that leverages flash Joule heating (FJH) to recover critical metals from e-waste with remarkable efficiency. Unlike conventional recycling methods, which often utilize energy-intensive procedures such as hydrometallurgy or pyrometallurgy, this new technique minimizes the use of harmful chemicals and high-energy processes. By passing an electric current through e-waste, the material is subjected to rapid heating that facilitates the recovery of metals like gallium, indium, and tantalum. This method not only promises a significantly cleaner process but also optimizes the yield and purity of the recovered metals.

One of the most compelling advantages of this innovative method is its potential to lessen the ecological impact of metal recycling. Traditional techniques are notorious for their high energy consumption and generation of toxic waste. In contrast, this new process minimizes the use of acids and solvents, dramatically reducing byproducts that typically pose a threat to the environment. According to Tour, the operational costs and greenhouse gas emissions associated with metal recycling are significantly lowered, marking an important step towards sustainable practices in the recycling industry. The economic implications are promising as they may encourage a shift towards more responsible recycling practices.

The research team, including co-authors from various disciplines at Rice University, is already exploring possibilities for expanding this technology to recover additional critical metals from e-waste. The versatility of the FJH technique shows promise for extracting not only metals previously mentioned but potentially lithium and rare Earth elements as well. This can have far-reaching implications for industries reliant on these materials, especially as global demand continues to rise amidst concerns over resource scarcity. The team’s findings, recently published in *Nature Chemical Engineering*, signal a hopeful future for those seeking sustainable solutions to the e-waste problem.

The innovative efforts of Rice University’s research team present a substantial leap forward in recycling technology. By utilizing advanced methods that prioritize environmental responsibility while simultaneously addressing the economic challenges of metal recovery, they are paving the way for a more sustainable approach to e-waste management. As this technology matures and expands into broader applications, the hope is that it will not only alleviate the pressures of metal shortages but also nurture a global culture of recycling that values ecological health and resource sustainability. The significant advancements made in this field underscore a promising trajectory toward a cleaner and more responsible future in electronic waste management.

Leave a Reply