Materials, much like living organisms, are inherently dynamic entities. They undergo transformations in structure and behavior in response to external stimuli—be it mechanical stress, environmental changes, or thermal fluctuations. Understanding these shifts is crucial for the advancement of diverse fields, including manufacturing, nanotechnology, and pharmaceuticals. The challenge, however, lies in observing and quantifying these subtle metamorphoses. Recent innovations have illuminated a path forward, merging advanced imaging techniques with cutting-edge artificial intelligence.

The Intersection of X-Ray Photon Correlation Spectroscopy and AI

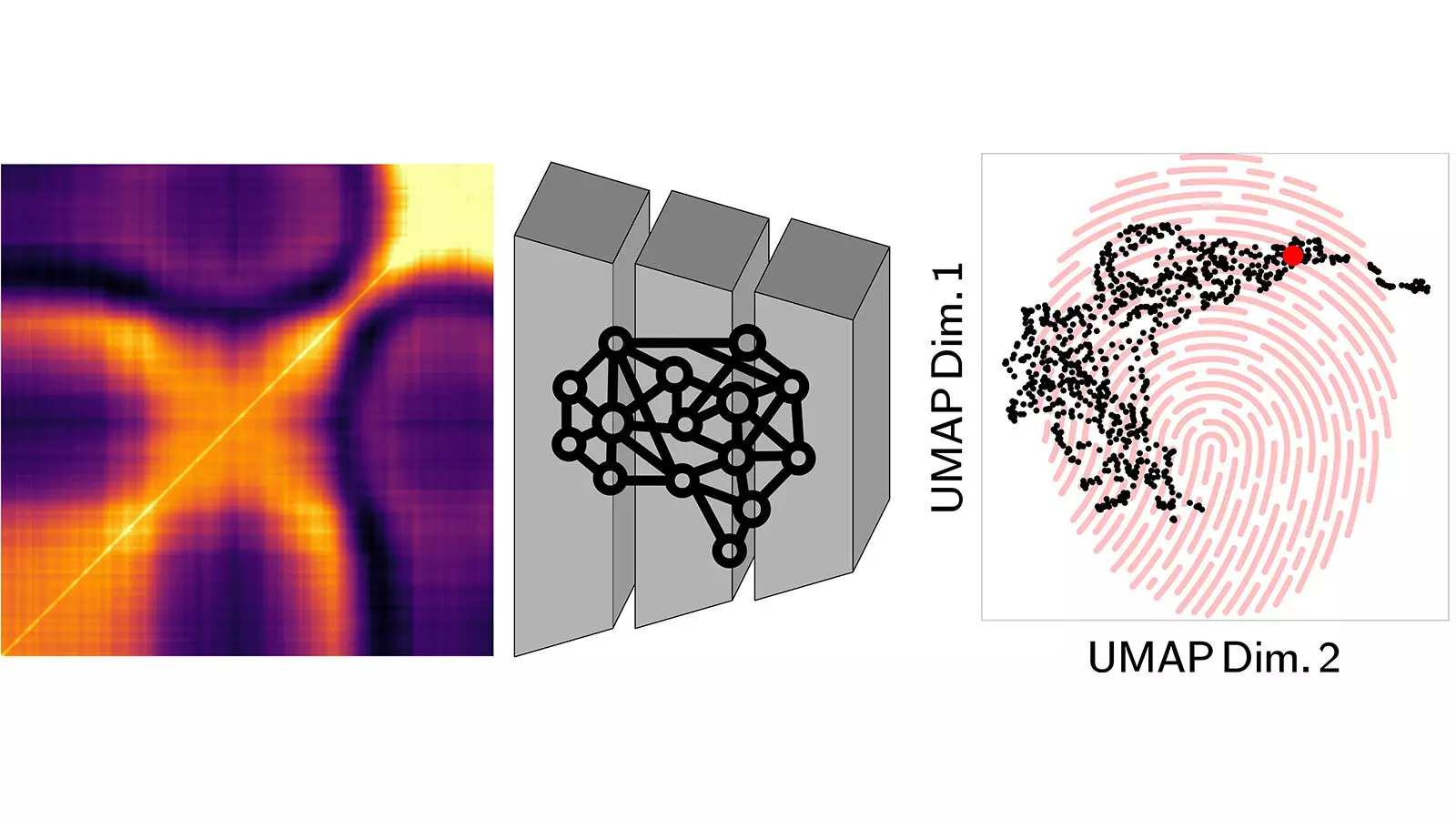

At the forefront of this scientific frontier is X-ray photon correlation spectroscopy (XPCS), a revolutionary technique that allows researchers to peer deep into the minutiae of material behavior at the atomic level. Coupled with artificial intelligence and machine learning, specifically an unsupervised learning algorithm, scientists have initiated a paradigm shift in material characterization. This innovative approach generates unique “fingerprints” for different materials—specific patterns derived from X-rays scattered by a colloidal solution of particles. The capacity of AI to autonomously recognize and categorize complex data patterns is akin to a seasoned detective unveiling the intricate web of a mystery.

Postdoctoral researcher James (Jay) Horwath from the Advanced Photon Source (APS) and the Center for Nanoscale Materials (CNM) has been pivotal in this research. He notes that XPCS generates patterns that are overwhelmingly intricate, often surpassing human analysis capabilities. By leveraging AI, researchers can filter through vast amounts of X-ray scattering data, pinpointing essential features that encapsulate the behavior and characteristics of materials. This collaboration of human intellect with machine efficiency enables a level of insight that was once unimaginable.

Mapping the Material Genome

Conceptually speaking, the process of creating material fingerprints through the proposed technique serves a function similar to decoding a genetic sequence. Just as a genome holds the blueprint for biological traits, these fingerprints condense complex scattering data into digestible formats. The AI-NERD initiative—Artificial Intelligence for Non-Equilibrium Relaxation Dynamics—focuses on fleshing out a comprehensive map of these fingerprints, allowing for a visual representation of the material’s behavior over time. This mapping not only uncovers individual characteristics but also clusters similar features together, leading to an enriched understanding of how materials evolve under various conditions.

The use of autoencoders—a type of neural network designed to condense and reconstruct data—facilitates this remarkable transformation. By converting extensive datasets into latent representations, the autoencoder aids researchers in visualizing the inherent patterns and structures within their materials. This serves as a beacon, illuminating the relationships between stress, relaxation, and structural coherence, which are pivotal for practical applications ranging from new material development to quality control processes.

AI: The Unseen Catalyst in Material Dynamics

Utilizing AI in the context of material science research is not merely an academic exercise; it represents a significant leap forward in efficiency and insight. The capabilities of AI to systematically process vast datasets redefine the boundaries of what scientists can achieve. By treating X-ray scattering patterns as images, AI is adept at deciphering repeating motifs and anomalies that would otherwise elude human oversight. As the upgraded APS prepares to deliver dazzlingly bright X-ray beams—up to 500 times more intense than its predecessor—the reliance on AI becomes even more critical. This substantial increase in data generation necessitates sophisticated analytical methods, thereby underscoring the essential role of artificial intelligence in ensuring no valuable information slips through the cracks.

Moreover, this blend of theoretical and computational approaches creates a robust framework for simulating polymer dynamics alongside experimental data—further enhancing the credibility of findings and allowing for experimental design that is tightly aligned with theoretical predictions. The collaboration between theory groups and computational experts at Argonne National Laboratory signifies a thoughtful effort to bridge the gap between data acquisition and analysis, effectively marrying cutting-edge science with pragmatic application.

Future Implications and Scientific Collaboration

As the fields of material science and AI continue to converge, the implications are profound. The ability to effortlessly generate and analyze material fingerprints could lead to breakthroughs in multiple domains, from improving material durability to optimizing nanostructure designs for various industrial applications. However, these advancements are made possible through collaborative efforts involving multiple research teams, bringing diverse expertise into a cohesive scientific dialogue.

As researchers like Horwath and his colleagues push the boundaries of what is achievable through innovative methodologies, the future of material science gleams brightly on the horizon. Those willing to embrace the power of AI in their arsenal will surely lead the charge into uncharted territories of discovery and innovation, unearthing truth and knowledge that could benefit various sectors for years to come.

Leave a Reply