In today’s world of rapidly advancing technology, we often find ourselves faced with the challenge of effectively interfacing hard and soft materials. Whether it’s a laptop charger that breaks at the cable-adapter junction or the need to optimize the interface between man-made materials, the limitations of existing methods have sparked the curiosity of researchers. In a groundbreaking study, TU Delft researchers have used a unique 3D printing process to create hybrid multi-material interfaces that closely mimic the design of bone-tendon connections found in nature. Published in Nature Communications, their findings have the potential to revolutionize various industries and open up new opportunities for innovation.

One of the fundamental challenges in material interfaces is the mismatch between the hardness of different materials. When two materials with different hardness levels are connected, it often results in stress concentration at the interface. This stress concentration can lead to failure of the softer material, causing issues in various applications. However, nature has provided us with a solution – the gradual change in properties at interfaces. As Professor Amir Zadpoor explains, “A hard material doesn’t suddenly become a soft material, it changes gradually, and that smooths out the stress concentration.”

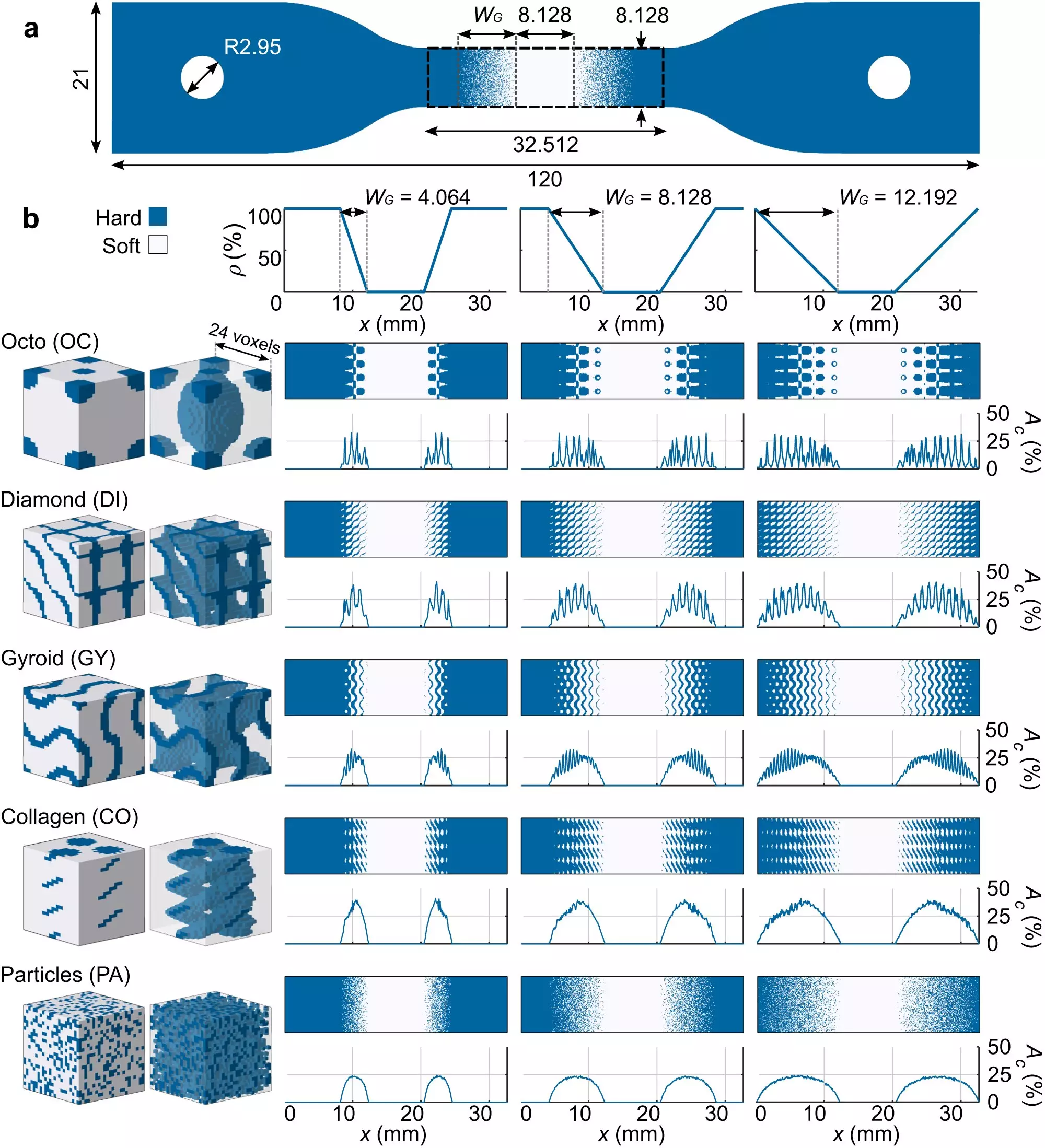

Inspired by the bone-tendon connection in the human body, the researchers at TU Delft sought to optimize the hard and soft interfaces of man-made materials. They used different geometries and a multi-material 3D printing technique to increase the contact area between these interfaces, mimicking nature’s design. By doing so, they were able to enhance toughness values of interfaces by an impressive 50% compared to a control group.

The study not only achieved remarkable results but also established a set of design guidelines that can be universally applied to improve the mechanical performance of bioinspired soft-hard interfaces. These guidelines provide valuable insights for future research and development in this field.

One of the distinguishing features of the technique developed by the TU Delft researchers is its ability to create a whole product at once. Unlike traditional methods that involve the use of adhesives or assembly of parts, this approach streamlines the manufacturing process. Assistant Professor Zjenja Doubrovski explains, “We are trying to remove the extra steps and have everything in one go.” This not only saves time but also enables the combination of exotic materials with different properties, expanding the range of applicability.

Wide Range of Applications

The potential applications of this technology are vast and diverse. From medical devices and soft robotics to flexible devices, the possibilities are endless. The ability to create interfaces with living cells opens up even more opportunities. For instance, connecting implants to the surrounding soft tissue can be greatly improved by integrating living cells into the interface. Assistant Professor Mohammad J. Mirzaali envisions a future where bone regeneration and muscle-bone connections are made possible through this groundbreaking technology.

In addition to the immediate applications, the results of this research pave the way for a whole new realm of studies and possibilities. By pushing the boundaries and approaching the theoretical limit of what is possible, the TU Delft researchers have sparked curiosity and ignited a passion for further exploration and innovation.

The groundbreaking research conducted by TU Delft researchers in the field of 3D printing and material interfaces has the potential to revolutionize various industries and open up new frontiers of possibility. By emulating nature’s design and developing innovative techniques, the researchers have achieved remarkable results and established guidelines for future improvements. The ability to create whole products at once and combine various materials further expands the range of applications. This work exemplifies the power of interdisciplinary research and the remarkable potential that lies at the intersection of biology and engineering. As we move forward, the door is wide open for future studies and new discoveries. The future of material interfaces is exciting, and the possibilities are limitless.

Leave a Reply