In today’s rapidly evolving technological landscape, the manipulation of fluids is pivotal across a myriad of industries, from healthcare and pharmaceuticals to chemical engineering and biotechnology. The challenge persists in designing systems that can adeptly manage the capture and release of varied chemical and biological fluids with high precision. This has been a thorny issue for researchers and engineers alike. The ability to achieve spatial and temporal control over fluid handling is not merely a technical concern but a fundamental requirement that underpins innovations and efficiencies in these critical sectors.

A recent study conducted by researchers at The Polytechnic University of Hong Kong introduces a dynamic solution to this challenge. Spearheaded by Prof. Wang Liqiu and detailed in the prestigious journal *Nature Chemical Engineering*, the research puts forth the concept of “Connected Polyhedral Frames” (CPFs). This innovative fluidic processor emerges as an advanced meta-metamaterial that allows for reversible liquid capture and release mechanisms. The first author of the study, Dr. Zhang Yiyuan, outlines how CPFs enable seamless transitions between capturing and releasing fluids, independent of the polyhedral arrangements and the fluids themselves.

This breakthrough addresses a long-standing limitation in fluid manipulation, which contrasts significantly with the established technologies in solid material handling. Despite the ubiquity of fluids in diverse applications, their management often leads to complications such as incomplete liquid transfer and cross-contamination—issues that are detrimental to accuracy and reliability in measurements, particularly in critical environments like laboratories and hospitals.

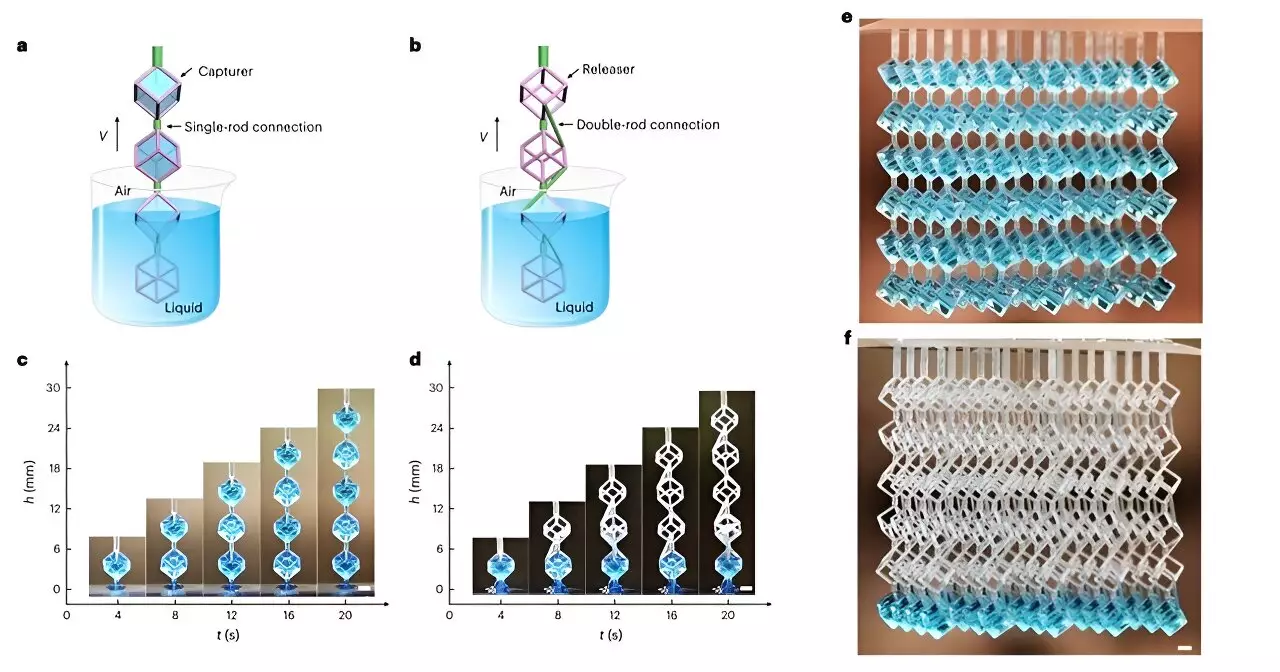

At the core of the CPF technology lies an ingenious design that facilitates dynamic liquid handling. The framework consists of various configurations that allow liquids to be captured and retained or released with remarkable precision. Specifically, the design utilizes single-rod and double-rod connections to dictate its functionality: while certain frames act as liquid capturers by retaining fluids, others serve as releasers by establishing liquid channels upon reintegration with the surrounding environment.

This ability to rapidly switch between functions enhances the CPF’s utility significantly. By simply altering the connectivity of the system, users can control liquid flow on-demand, thereby facilitating extensive applications ranging from 3D patterning of diverse substances to large-scale manipulation of liquid arrays. Such versatility is crucial for modern applications where effectiveness and efficiency are key.

One standout application of CPFs is in the realm of pharmaceuticals, particularly demonstrated through the controlled release of vitamins B2 and B12 encapsulated within gel matrices. This process showcases the potential of CPFs to finely regulate the release rates of various compounds, providing a precise means to deliver medications. In stark contrast to traditional sampling tools, such as cotton or flocking swabs, which suffer from significant material residue hindering sample retrieval, CPFs leverage their design to ensure maximal release efficiency, particularly highlighted in the context of viral detection.

Beyond medical applications, CPFs also extend their novel capabilities to microbial processes. They enhance the encapsulation of beneficial bacteria, allowing for efficient separation of products while simplifying reaction processes. This innovation could pave the way for new biological applications that utilize unique encapsulation techniques.

The environmental benefits of CPF technology cannot be overstated. In an era where plastic waste poses a significant threat to ecosystems, the employment of CPFs in applications like air conditioning with high water storage capabilities is a step toward efficiency and sustainability. The potential for integrated CO2 cycles for carbon capture challenges traditional methods, showcasing CPFs’ role in addressing the global climate crisis.

As these frameworks develop further, the implications of CPFs reach far beyond their initial applications. Their adaptability heralds a new frontier in meta-metamaterials research, presenting opportunities for breakthroughs in fluid dynamics that could radically transform industries. With additional advancements, researchers could unlock even more nuanced capabilities, allowing for better management of resources that are critical to health, industry, and the environment.

Ultimately, Connected Polyhedral Frames represent a significant leap forward in fluid technology. This innovative system not only addresses long-held challenges in fluid manipulation, offering a revolutionary approach to fluid handling but also sets a new standard for future research and applications. With its versatile capabilities and potential for widespread adoption, CPFs are poised to impact various fields significantly, driving forward scientific and technological innovations that could reshape our understanding of fluid dynamics.

Leave a Reply