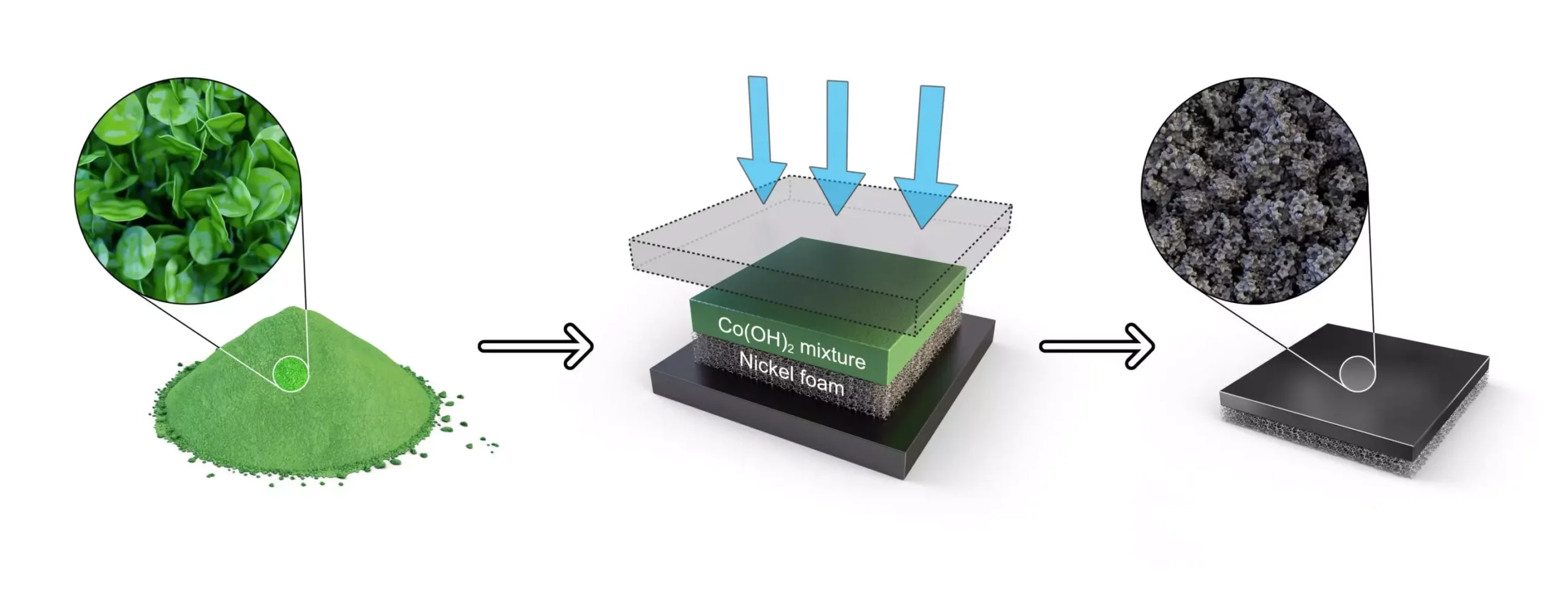

The research team led by Dr. Sung Mook Choi at the Korea Institute of Materials Science has made a groundbreaking discovery in the field of anion exchange membrane water electrolysis. They have developed a one-step electrode fabrication process, which marks the first of its kind in South Korea. This innovative process, detailed in the journal Applied Energy, streamlines the production of electrodes from raw materials to a mass-producible level. By utilizing a one-step hot-pressing process, cobalt hydroxide is converted into a cobalt oxide catalyst, creating a highly uniform catalyst layer in the electrode.

Through the new electrode fabrication process, the team was able to simplify the complex steps involved in traditional methods by 60%. This streamlined approach not only enhances efficiency but also ensures the creation of a uniform catalyst layer. The efficiency of hydrogen production and the durability of the electrode during continuous operation were found to be significantly improved with this new process. The study also demonstrated that by carefully controlling the cobalt hydroxide slurry conditions, temperature, and pressure, uniform oxide particles of 10 nanometers in size could be achieved.

Development of Membrane Electrode Assembly

The developed electrode was further used to fabricate a membrane electrode assembly (MEA) incorporating an anion exchange membrane and a hydrogen evolution catalyst. The stability and performance of this assembly were successfully confirmed in a commercial-scale water electrolysis cell. This crucial development paves the way for stable anion exchange membrane water electrolysis with high hydrogen generation efficiency and a low degradation rate, showcasing the potential for widespread adoption of this technology.

The advancements in green hydrogen production through water electrolysis are set to reach unprecedented levels by 2030, with the potential for 11 million tons and 69 gigawatts of capacity. In Korea, efforts are already underway to develop technology for a megawatt-level anion exchange membrane water electrolysis system by 2024, with plans for commercialization by 2030. By achieving these milestones, Korea aims to localize the technology and secure a global edge in related fields.

Dr. Sung Mook Choi, the principal researcher behind this groundbreaking discovery, emphasized the importance of the one-step hot pressing electrode fabrication process in addressing key challenges related to the commercialization of anion exchange membrane water electrolysis. By securing the source technology for mass-produced electrode manufacturing, Korea is poised to dominate overseas water electrolysis markets and become a leader in cutting-edge water electrolysis technology.

The research team’s pioneering work in developing a new electrode fabrication process has the potential to revolutionize the field of anion exchange membrane water electrolysis. With improved efficiency, durability, and performance, this technology has opened up exciting possibilities for the future of green hydrogen production. By focusing on localization and core original technology, Korea is on track to become a global powerhouse in water electrolysis technology.

Leave a Reply