Recent advancements in 3D printing at the University of California San Diego offer a promising new method that utilizes simple ingredients and environmentally friendly processes to create solid structures. Researchers have introduced a technique involving a unique polymer ink, poly(N-isopropylacrylamide) or PNIPAM, in conjunction with a calcium chloride salt solution. This groundbreaking study, published in *Nature Communications*, stands out for its simplicity, efficiency, and potential to significantly reduce the ecological footprint of material manufacturing.

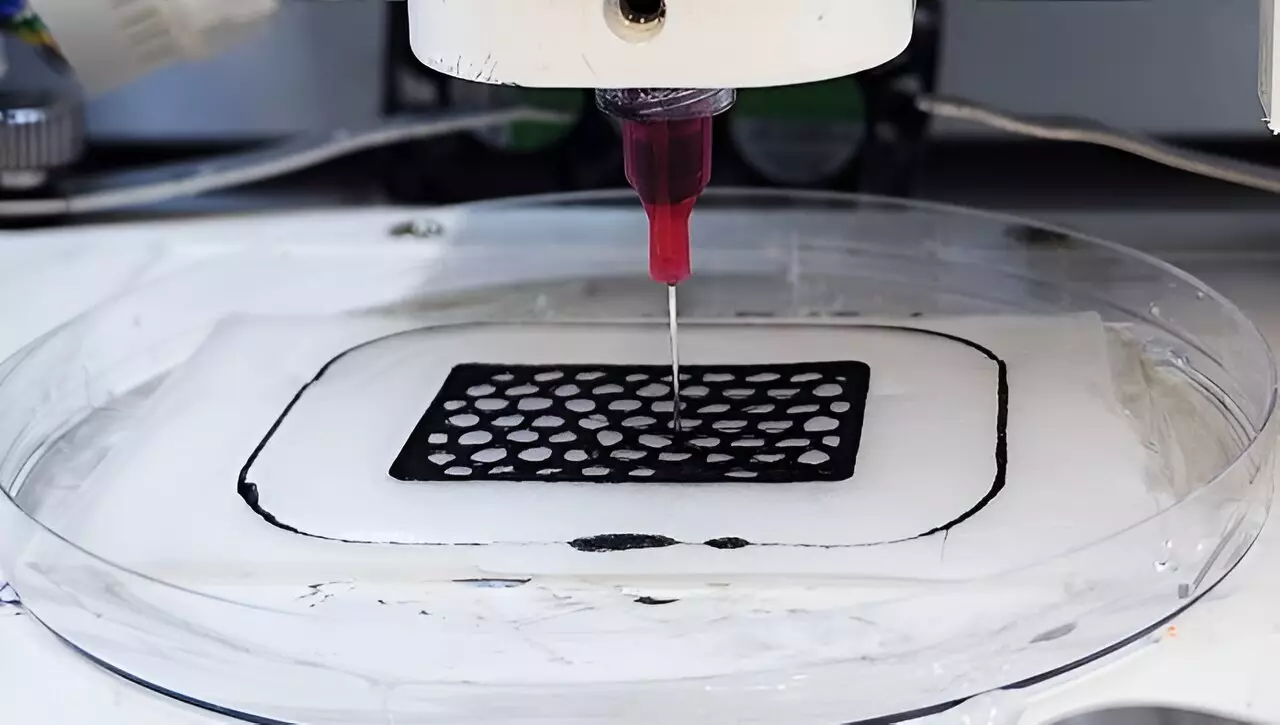

The process hinges on an interaction between the PNIPAM ink and the saltwater solution, leading to a rapid solidification effect. When the polymer solution is extruded into the calcium chloride bath, the ink instantly hardens upon contact, thanks to the salting-out effect. This phenomenon occurs as the salt ions attract water molecules from the polymer, causing the hydrophobic chains in the PNIPAM to aggregate tightly. This method ingeniously sidesteps the energy-intensive and often toxic steps typical of traditional polymer solidification processes. Senior author Jinhye Bae emphasizes that all these processes occur under ambient conditions, eliminating the need for specialized equipment and hazardous chemicals.

One of the most significant advantages of this innovative method is its sustainability. Unlike conventional techniques that may yield harmful waste and consume substantial energy, the UC San Diego team’s approach leverages a natural interaction that happens at room temperature. This means manufacturers can create solid structures without incurring high environmental costs. Furthermore, the structures produced through this technique are reversible; they can be easily dissolved back into liquid form using fresh water. This feature not only enhances the recyclability of the materials used but also positions this method as a catalyst for future advancements in eco-friendly manufacturing technologies.

To highlight the versatility of their technique, the research team explored printing complex structures by incorporating other materials alongside the PNIPAM ink. A noteworthy demonstration featured the creation of an electrical circuit using an ink formulation that included carbon nanotubes. This circuit successfully powered a light bulb, showcasing the method’s potential for developing water-soluble electronic components that can also be recycled. The implications of these findings could be transformative, extending beyond simple structures to complex and functional electronic systems that maintain environmental integrity.

Overall, the work emanating from UC San Diego not only pushes the boundaries of material science but also pioneers a trail towards greener manufacturing practices. By simplifying the 3D printing process and promoting the recycling of materials, this research holds the promise of generating a substantial impact in the field of sustainable manufacturing. As more industries seek to adopt eco-friendly technologies, this reversible, low-impact method could play a critical role in redefining the landscape of polymer production, setting a new precedent for future innovations.

Leave a Reply