The field of electronics has seen significant advancements in recent years, leading to the creation of smaller and more sophisticated devices such as wearable technologies, biosensors, medical implants, and soft robots. The majority of these technologies rely on stretchy materials with electronic properties. However, many of the flexible materials used in these devices are fragile and prone to damage, which can compromise their overall functioning. To address this issue, researchers at Harbin University of Science and Technology in China have developed a new conductive and self-healing hydrogel that could be used to create flexible sensors for wearables, robots, or other devices.

The Material

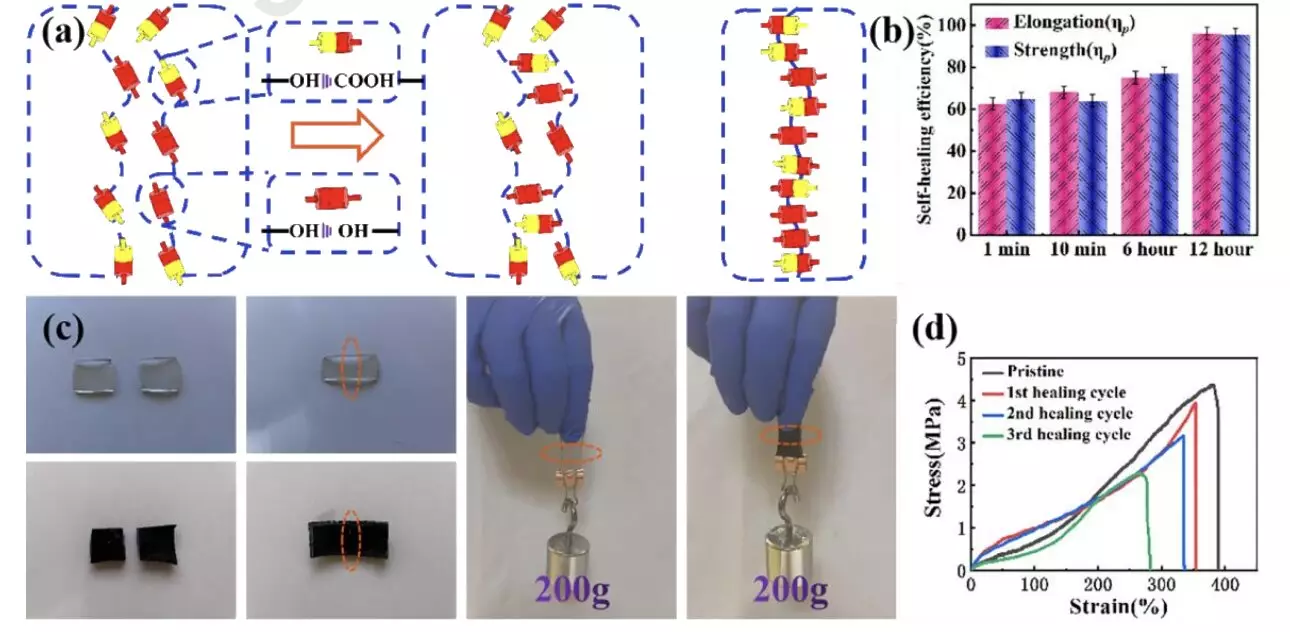

The researchers used polyvinyl alcohol (PVA) and 4-carboxylbenzaldehyde (CBA) to form a double network skeleton and introduced polyaniline (PANI) to assemble a flexible sensor with excellent self-healing performance. The hydrophobic association of PVA and CBA guarantees the mechanical properties of the hydrogel sensor, and the introduction of PANI brings electrical properties to the hydrogel sensor. The team created their material by introducing CBA, an organic compound consisting of a benzene ring substituted with an aldehyde and carboxylic acid, into PVA, a water-soluble synthetic polymer, and adding the conducting polymer PANI via an electrostatic interaction. In initial tests, they found that the material had remarkable mechanical properties and could heal itself after being damaged. Moreover, it could reach a maximum stress of 4.35 Mpa and a maximum strain of 380%.

The Sensor

The researchers used the material to create a strain sensor, a sensing device that can detect external forces and applied pressure originating from its surroundings. This sensor was found to perform very well, measuring both small deformation signals, such as a wearer coughing or speaking, as well as more vigorous body movements. The flexible sensor prepared in this article has a sensitivity of 1.71 in the strain range of 0–300%, and a limit detection strain of less than 1%. The response time of the hydrogel sensor during stretching is 158 ms. In addition, the hydrogel sensor also has self-healing performance. At room temperature, after the hydrogel is cut, it only takes one minute to complete the repair, and the self-healing rate is about 60%.

The Future

The hydrogel created by this team of researchers could be used to develop a wide range of other sensors and wearable electronics, such as sensors that can detect human motion or medical devices that monitor specific biological signals. In addition, their work could pave the way for the development of similar flexible and conductive hydrogels with self-healing properties. The new material has the potential to revolutionize the wearable sensor technology industry by providing a durable and reliable material for use in sensors. The team’s work is a significant step forward in the development of flexible and self-healing sensors, and it will be exciting to see how this technology will be used in the future.

Leave a Reply