The field of material science is on the brink of a significant transformation with the introduction of a new oil-free super-lubricant derived from potato proteins. This breakthrough, spearheaded by researchers at the University of Leeds, promises to reshape sustainable engineering and biomedical applications through innovative materials that emulate the natural properties of biological substances. By focusing on developing lubricants that approach zero friction through a mechanism akin to natural synovial fluids found in human joints, this research opens new avenues for eco-friendly and efficient solutions in engineering and health-related fields.

Historically, the quest for effective aqueous lubricants has been fraught with challenges, primarily due to the reliance on synthetic materials. Many available products are dominated by compounds derived from synthetic chemistry, which raises concerns over sustainability and environmental impact. The interdisciplinary team at the University of Leeds, with collaborators from esteemed institutions such as the Weizmann Institute of Science, King’s College London, and INRAE in France, has made substantial progress in creating a lubricant that leverages the power of potato protein—an organic and lower-carbon-footprint alternative. This innovative approach marks a pivotal step towards producing sustainable, plant-based lubricants suitable for various applications.

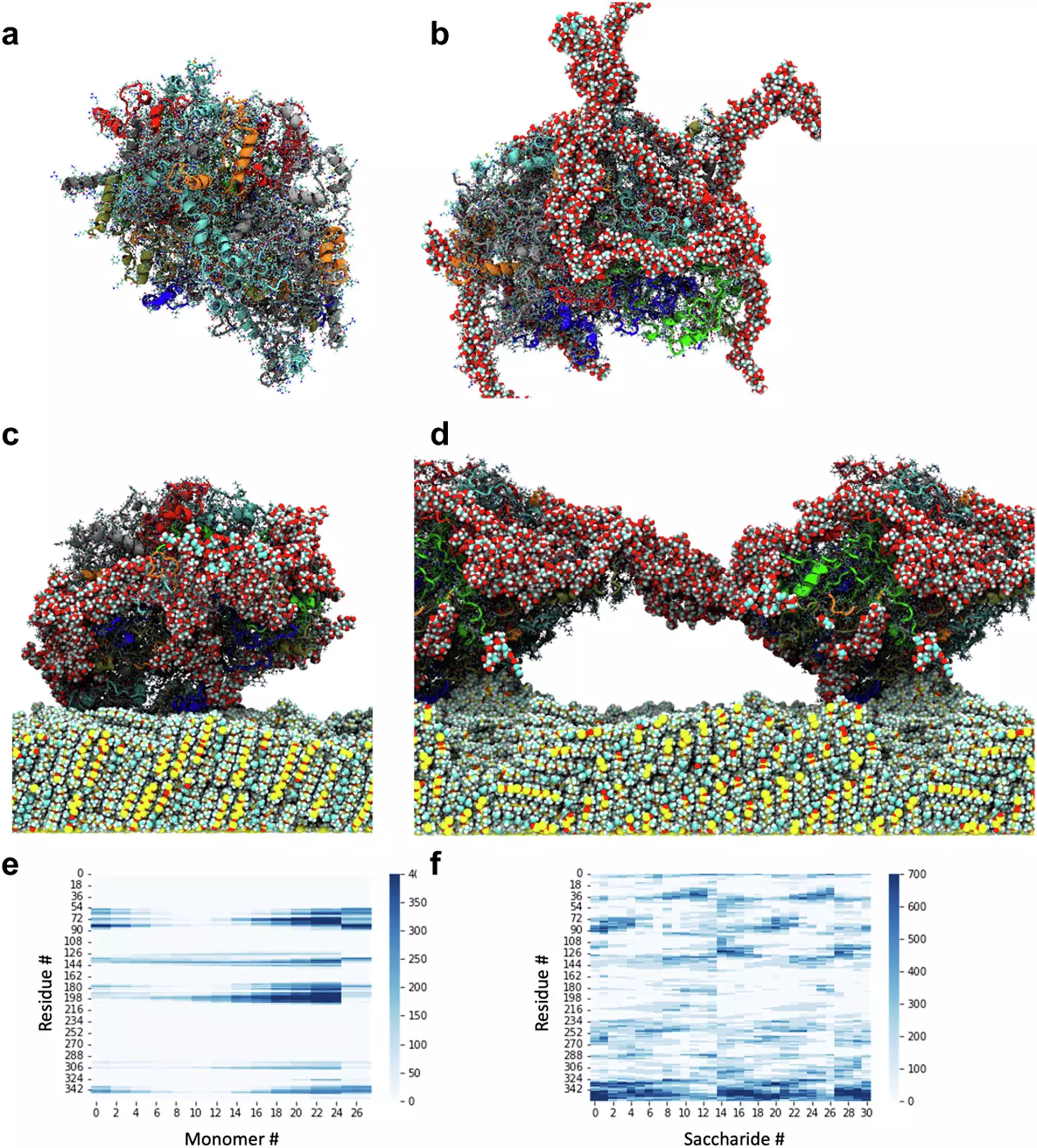

Under the guidance of lead author Professor Anwesha Sarkar, the project involved constructing plant protein-based protofilaments combined with biopolymeric hydrogels, which form a unique architecture conducive to super lubricity via hydration lubrication. This self-assembly process is groundbreaking, as it not only provides practical lubrication solutions but also mirrors the complexities of nature. The culmination of this work emphasizes how nature can inspire technologically advanced solutions, fostering a deeper understanding of biological processes to enhance engineered materials.

First author Olivia Pabois, a postdoctoral fellow in the School of Food Science and Nutrition, emphasized the potential applications of their findings, which go beyond industrial lubricants. The research opens possibilities for developing next-generation biomedical materials such as artificial synovial fluids and other vital bodily fluids like tears and saliva. Furthermore, this material could contribute to the food industry, enabling low-fat products that retain desirable textures—the proverbial “holy grail” in food technology.

Collaborative Approach and Scientific Rigor

The research exemplifies the strength of international collaboration, with scientists leveraging each other’s specialized knowledge to achieve remarkable outcomes. The project was carried out at the Weizmann Institute’s comprehensive research facilities, which provided state-of-the-art techniques essential for measuring surface forces and analyzing the lubricants’ surface morphology. Professor Jacob Klein pointed out that this collaborative effort, which initiated with communications between various experts in 2019, showcases an important synergy where collective knowledge leads to breakthroughs that no single entity could accomplish alone.

The integration of molecular dynamics simulations—a sophisticated modeling technique used by the King’s College London team—was crucial in linking microscopic interactions to observable lubrication properties. Professor Chris Lorenz highlighted how this meticulous examination of interactions among plant proteins and hydrogels could lead to the intentional design of self-assembled natural materials, ultimately optimizing their lubricating abilities.

The implications of this research extend far beyond basic lubricants. As we journey toward a more sustainable future, the introduction of biologically-inspired materials sets a precedent for how we can intertwine nature with technology. This potato protein-derived super-lubricant exemplifies a shift in perspective that prioritizes environmental sustainability without sacrificing functionality.

The remarkable advancements detailed in this research challenge conventional notions of lubrication, simultaneously addressing environmental concerns while paving the way for innovative biomedical applications. As the demand for sustainable materials continues to rise, this groundbreaking work could act as a catalyst for further exploration into plant-based technologies, marking a significant milestone on the road to sustainable engineering and improved healthcare solutions.

Leave a Reply