Recent advancements in electrochemical processes are reshaping the landscape of chemical production, promoting cleaner and more energy-efficient methods. Researchers at Lawrence Livermore National Laboratory (LLNL) have developed an innovative technique employing thin film nickel anodes. This breakthrough allows for enhanced understanding and streamlined catalytic reactions, ultimately leading to greener manufacturing protocols. Aditya Prajapati, a postdoctoral researcher on the team, underscores the advantages of utilizing thin films, stating that they offer a reliable surface which minimizes the complications inherent in porous or uneven structures and thickness variations. This precision allows for a clearer focus on the catalyst’s inherent properties, paving the way for significant improvements in chemical processes.

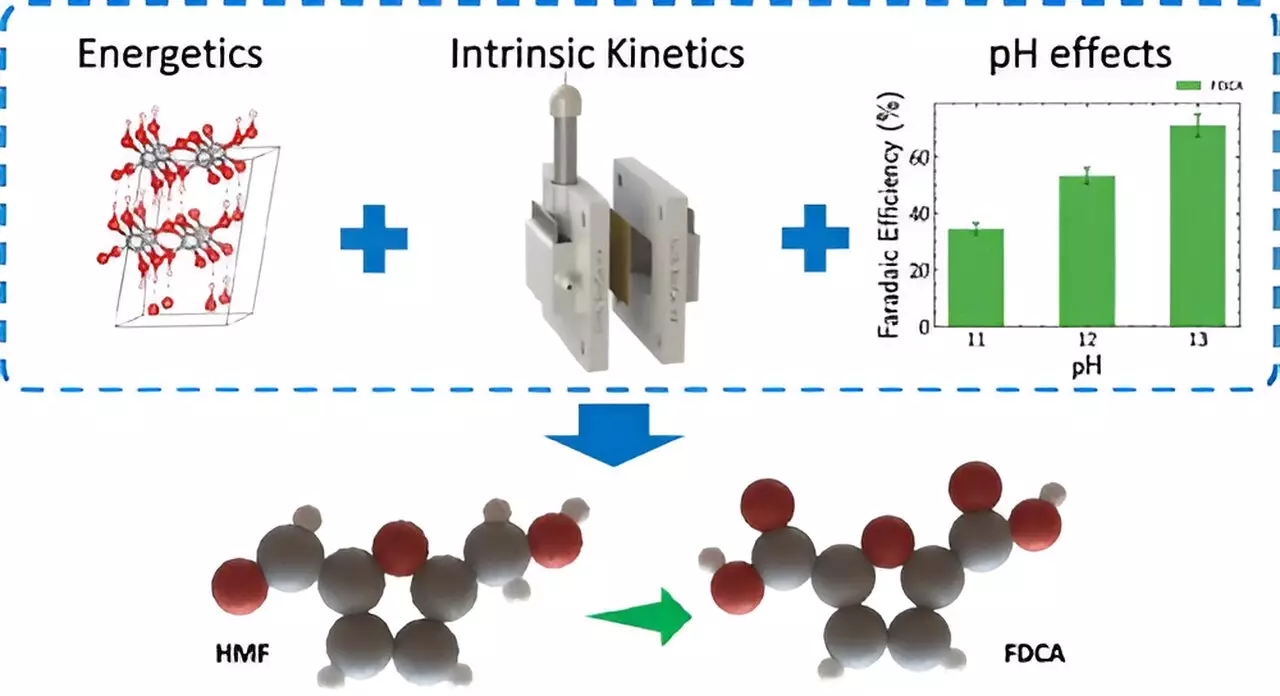

Conventional electrolyzers, devices responsible for converting electrical energy into high-energy-density molecules, frequently grapple with inefficiencies primarily linked to the oxygen evolution reaction that occurs at the anode. The LLNL team’s research presents a revolutionary alternative: substituting the energy-intensive oxygen evolution with biomass oxidation. This method not only improves the energy efficiency by over 50% but also addresses urgent sustainability concerns tied to biomass conversion methods. The conversion process entails transforming a compound known as 5-Hydroxymethylfurfural (HMF), harvested from biomass, into 2,5-Furandicarboxylic acid (FDCA). FDCA serves as a crucial building block for producing sustainable materials, such as polyethylene furanoate (PEF), a bio-based polymer anticipated to alleviate dependence on petroleum-derived plastics.

The implications of this electrochemical method extend far beyond energy savings; they significantly contribute to reducing overall environmental impact. Unlike traditional approaches which often necessitate extreme temperatures and generate harmful waste, the new process offers a cleaner and more energy-efficient alternative. Nitish Govindarajan, one of the project’s corresponding authors, highlights the method’s potential to diminish carbon emissions and petroleum reliance. By sourcing feedstock from renewable biomass, this technique not only facilitates a shift toward a circular economy but also curtails the exploitation of exhaustible fossil fuel reserves.

Furthermore, the electrochemical oxidation of HMF to FDCA requires considerably less energy when juxtaposed with conventional methodologies, which translates to a lower carbon footprint across the chemicals sector. The significance of this process is heightened, especially as it could potentially reach a near-zero carbon footprint when powered by renewable electricity sources. This elevates the method’s viability within a broader climate-conscious framework, offering a compelling vision for the future of sustainable chemical production.

The advancements produced by the LLNL team, alongside their partners from Université de Montréal and the University of Bonn, signify a promising shift towards environmentally responsible chemical manufacturing. By harnessing the potential of renewable materials and electrochemical techniques, the possibilities for cleaner, more efficient production are becoming increasingly tangible, marking an essential step forward in the quest for sustainability in chemistry.

Leave a Reply