The pursuit of sustainable energy sources has intensified in recent years, particularly as the global demand for clean energy continues to soar. One of the most promising strategies for achieving this goal is the utilization of hydrogen production via water electrolysis. At the heart of this process lies the oxygen evolution reaction (OER), which has traditionally posed significant challenges due to its slow reaction kinetics. Researchers have recognized the critical need for high-performance catalysts to enhance the efficiency of OER, as these catalysts play a vital role in ensuring that the electrolysis process occurs at optimal rates. Recent advancements have focused on developing cost-effective catalysts that can significantly reduce the energy input required for water splitting and enhance the overall efficiency of hydrogen production.

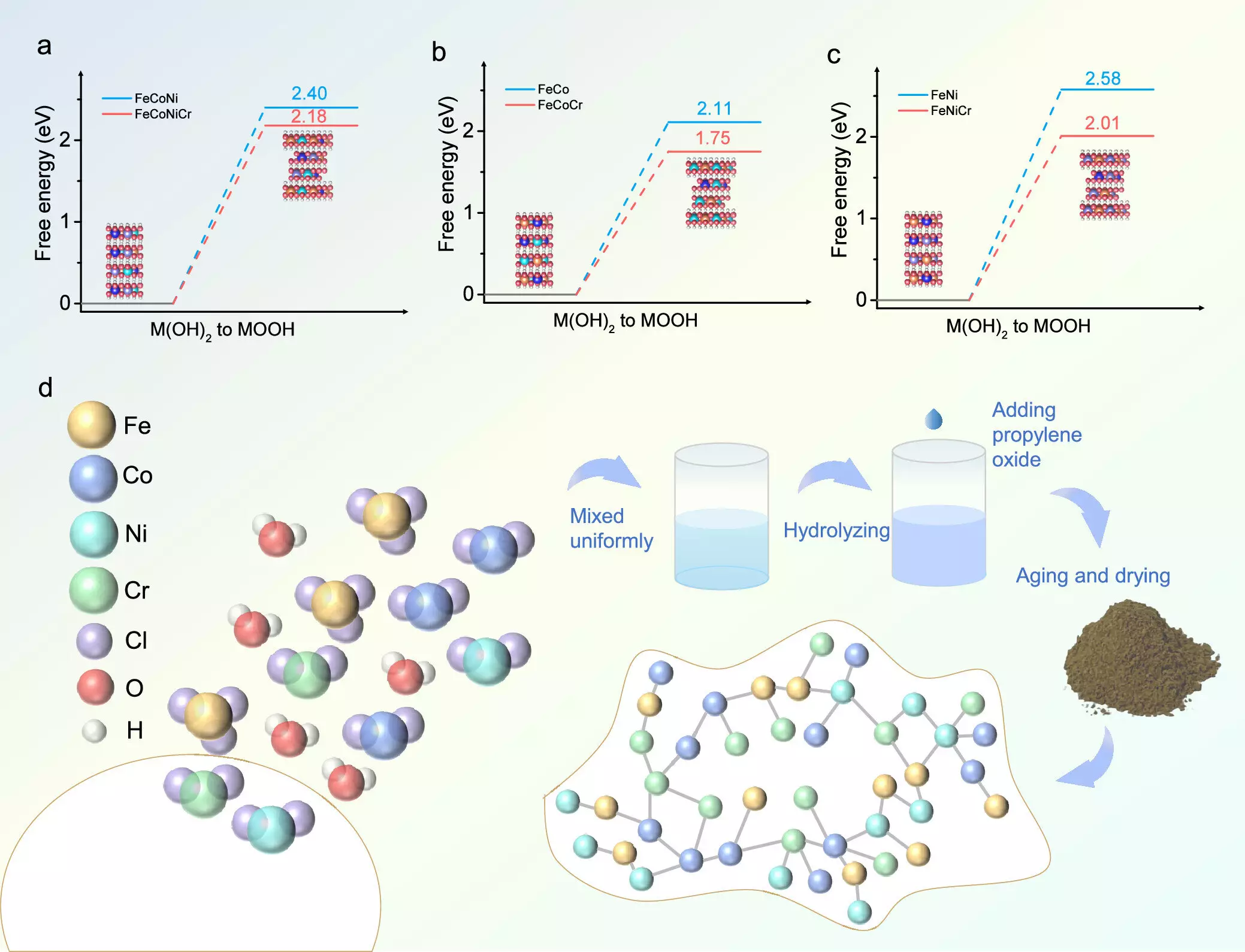

A pioneering study published in ACS Catalysis has shed light on an innovative approach to catalyst development. Researchers have successfully integrated chromium (Cr) into a matrix of transition metal hydroxides, resulting in a new catalyst that exhibits remarkable catalytic activity. Using a combination of theoretical calculations and experimental methods, the team has demonstrated that this doping process not only enhances the catalytic properties of the hydroxides but also facilitates a critical phase transition into an active oxyhydroxide state. This transformation is essential for maximizing OER efficiency, as highlighted by Hao Li, a member of the research team from Tohoku University’s Advanced Institute for Materials Research.

The catalyst engineered by the researchers, identified as FeCoNiCr hydroxide, was produced via an aqueous sol-gel method. Its performance metrics unveil a significant advancement in the field—showcasing an impressive low overpotential of 224 mV in alkaline environments, which is a substantial improvement over comparable catalysts. Notably, this new catalyst also maintained its stability over extended durations, withstanding more than 150 hours of continuous operation. Accompanying this success, a zinc-air battery assembled with the FeCoNiCr catalyst exhibited stable performance for 160 hours, minimalizing the discharge/charge voltage differential to just 0.70 V.

Delving deeper into the catalytic dynamics, the researchers utilized density functional theory (DFT) to confirm that chromium doping optimizes the adsorption characteristics of intermediate species involved in the OER. This refinement significantly enhances the reaction efficiency, thereby underscoring the role of Cr in the reaction pathway. Additionally, insights gained from Bader charge analysis showed that nickel and cobalt ions retained a favorable +3 oxidation state throughout the OER process, contributing to sustained catalytic activity.

Looking forward, the research team’s ambitions include experimenting with other elemental combinations to further refine catalyst performance. Di Zhang, a co-author of the study, emphasized the importance of establishing a comprehensive screening methodology to streamline the development of even more efficient catalysts. As the energy landscape continues to evolve, the need for advanced, durable catalysts becomes increasingly vital in accelerating the transition towards clean energy technologies, particularly in hydrogen production.

The proactive steps taken by researchers to innovate in catalyst design herald new opportunities for enhancing the efficiency of renewable energy systems. As we advance, the continued exploration of diverse materials will undoubtedly play a crucial role in addressing the global challenge of energy sustainability.

Leave a Reply