As technology continues to evolve at a rapid pace, modern microelectronic devices have become increasingly integral to our daily lives. However, a pressing issue looms over these devices: they are notoriously difficult to repair and nearly impossible to recycle. This quandary not only contributes to environmental waste but also underscores a broader need for sustainable practices within the electronics industry. In response to these challenges, researchers are exploring innovative solutions, particularly in the realm of adhesives, which could revolutionize the way we approach device repair and recycling.

A recent study published in the journal Angewandte Chemie highlights the fascinating world of bioinspired materials, particularly focusing on mussel adhesion. These marine creatures possess a remarkable ability to cling to surfaces underwater through their natural adhesives. Researchers have turned to mussels as a template for developing new adhesives that offer enhanced performance while allowing for “on-command” deactivation. This concept not only facilitates easier disassembly of electronic components but also paves the way for a more circular economy, where resources are reused rather than discarded.

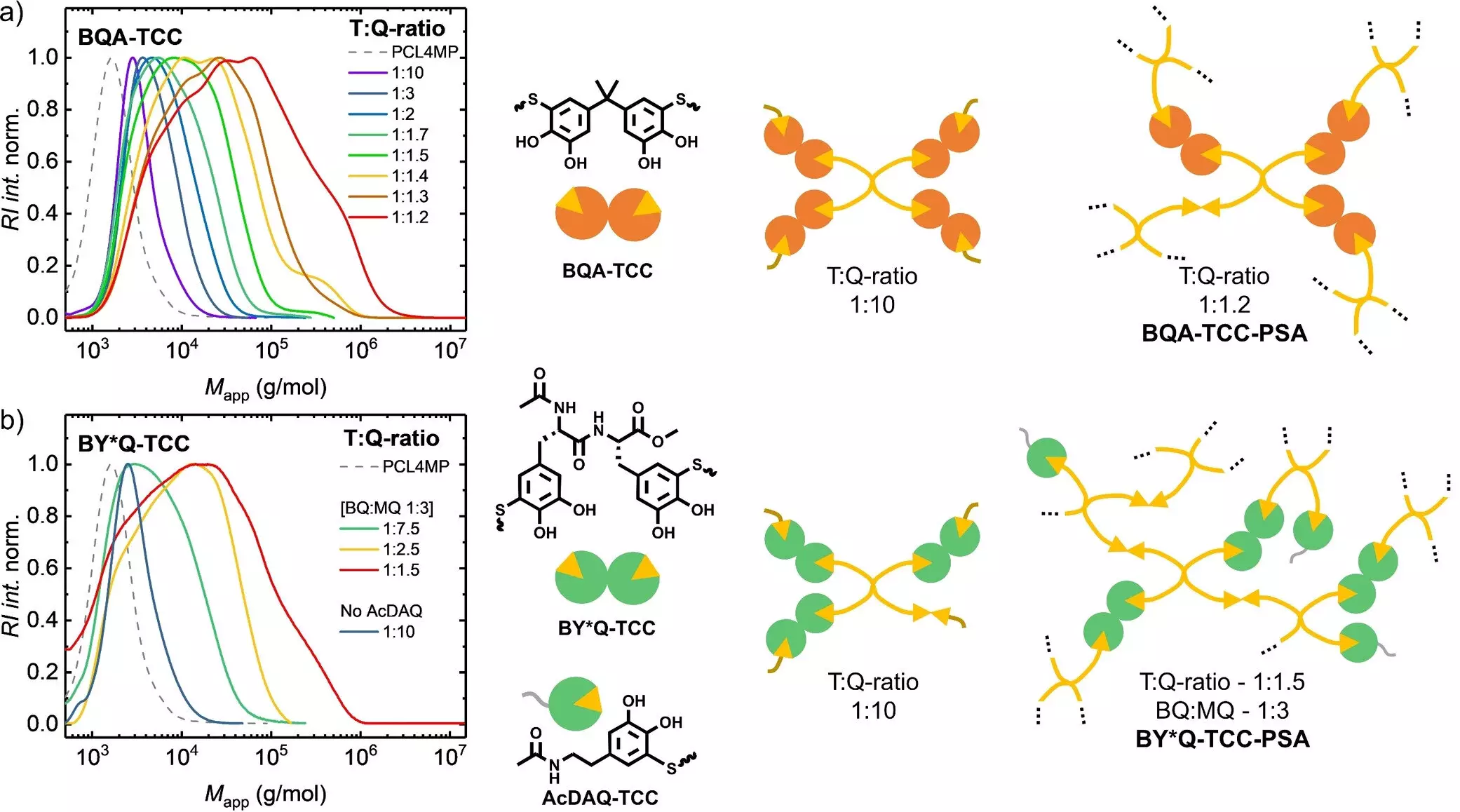

Researchers led by Kannan Balasubramanian and Hans Börner at Humboldt University have developed a novel approach to creating adhesives based on thiol-catechol polyaddition. This technique results in polymers with unique adhesive capabilities linked through what’s known as thiol-catechol connectivities (TCC). The critical breakthrough of this new adhesive lies in the ability to alter its adhesion properties through oxidation. Specifically, when the catechol groups in these polymers are oxidized to quinones, there is a significant reduction in adhesive strength. This property is particularly crucial for applications in microelectronics, as it allows for controlled disassembly without damaging components.

In their research, the team produced two distinct types of TCC adhesives—one biobased and the other fossil-based. The biobased adhesive incorporates peptidic biscatechol precursors similar to those found in mussels, demonstrating significant potential for sustainable applications. Both types of adhesives exhibit strong adhesion even in aqueous environments and are resistant to atmospheric oxygen as well as mild oxidizers. However, a notable difference arises when exposed to stronger oxidizing agents, such as sodium periodate (NaIO4). The biobased adhesive retains its adhesive properties while efficiently losing stickiness, making it easier to remove without residue.

On the other hand, the fossil-based adhesive experiences a dual effect during oxidation where it becomes more hydrophobic, thus complicating its removal. This presents a challenge for electronic recyclability, as leftover adhesive residues may hinder the seamless disassembly of devices.

One of the key advantages of the biobased adhesive is its multifunctionality, a characteristic often associated with biomaterials. As Börner notes, the fine balance between switching off specific functionalities without altering the material’s overall properties is paramount. This unique capability results in an impressive 99% reduction in adhesive strength upon oxidation, allowing components to be easily separated and repaired. Such advancements could ultimately transform practices within the electronics industry, guiding us toward a sustainable future where repairability supersedes disposability.

The research consortium is not resting on its laurels. Plans are already underway to enhance these innovative adhesives further by exploring alternative methods for deactivation, such as electrochemical oxidation. This approach could extend the functionality of these adhesives for various applications, including the repair of ubiquitous electronic devices like smartphones and tablets.

The development of smarter, repairable adhesives derived from biomimicry promises a significant shift in how we approach electronic device manufacturing, repair, and recycling. As scientists continue to explore the potential of materials inspired by nature, we stand on the brink of a revolutionary transformation that could redefine sustainability in the world of technology.

Leave a Reply