In the evolving landscape of construction materials, Ultra-High-Performance Concrete (UHPC) has emerged as a game-changer due to its remarkable strength, durability, and resistance to environmental factors. Engineers have increasingly turned to UHPC for applications requiring substantial structural integrity. However, as construction technology advances, the need for an in-depth understanding of UHPC’s behavior under various conditions has become apparent, particularly when combined with fiber-reinforced polymers (FRP). A newly published study signifies a leap forward in this area by providing a robust analysis-oriented stress-strain model that enhances the comprehension and application of UHPC confined by FRP.

Conducted by a team comprising researchers S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie from Huazhong University of Science and Technology and Southern University of Science and Technology, the study addresses a significant gap in existing structural engineering models. The focus was on the compressive behavior of FRP-confined UHPC, an area that has not been adequately covered by traditional models, which are primarily designed for normal-strength concrete (NSC). The researchers embarked on this project with the intention of unraveling the complexities associated with UHPC’s performance under concentric compression when supported by FRP.

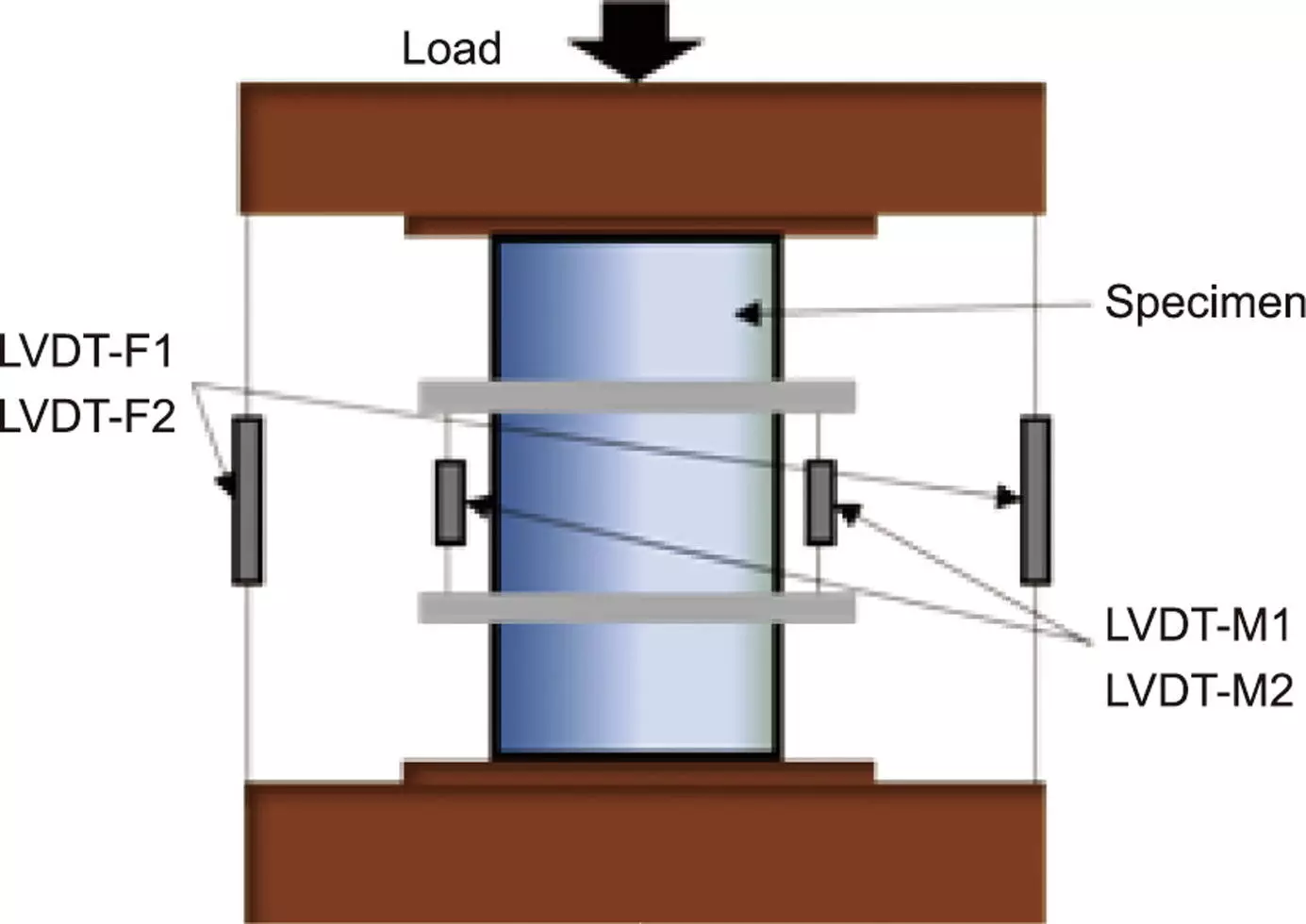

One of the critical challenges highlighted in the research is the assumption of stress-path-independency, a principle that has worked effectively for NSC confined by FRP but fails in the case of UHPC. Through comprehensive experimental analysis, the team discovered that UHPC exhibits unique failure mechanisms, including the formation of major diagonal cracks and non-uniform lateral expansion. These phenomena ultimately reduce the effective confining pressure from the FRP onto the UHPC, contradicting the assumptions of traditional models.

To challenge these existing paradigms, the researchers developed a thorough analysis-oriented model that factors in stress-path dependency. This new model addresses the limitations of prior methodologies by modifying the representation of confining pressure and introducing an equation specifically designed to account for the confining pressure gap. These adaptations result in a more accurate characterization of UHPC’s behavior under pressure. The thorough validation process, which included a detailed examination of a robust database of experimental results, confirmed the efficacy of this novel model in predicting the stress-strain behavior of FRP-confined UHPC.

The implications of this research extend far beyond academic understanding; they offer practical solutions for engineers engaged in the design and construction of UHPC structures. With an improved understanding of UHPC’s compressive behavior, engineers can create more reliable and safer designs, potentially transforming construction practices. As the construction industry faces new challenges, especially in terms of sustainability and efficiency, this research provides a critical tool for enhancing the performance and longevity of high-performance concrete structures.

This study not only marks a pivotal moment in concrete science and structural engineering but also paves the way for ongoing research initiatives. The enhanced understanding of FRP-confined UHPC behavior opens doors for further studies, potentially leading to the development of even more sophisticated materials and methods that could revolutionize construction. As engineers and researchers build upon these insights, the result will likely be advanced applications of UHPC, fulfilling the industry’s ever-increasing demand for innovative and resilient construction solutions.

The introduction of an analysis-oriented stress-strain model for FRP-confined UHPC represents a significant stride in structural engineering. By addressing critical knowledge gaps and refining existing models, researchers are not only enhancing the safety and efficacy of future constructions but also inspiring a new era of engineering that leverages the immense potential of ultra-high-performance concrete.

Leave a Reply