Cellulose, a versatile and abundant material, holds great potential for various applications, including hydrogel production for drug delivery, wound care, and contact lenses. However, the conventional methods of creating cellulose hydrogels often involve toxic or unstable solvents, making it challenging to develop eco-friendly and non-toxic processes. Inspired by the nest-building techniques of swift birds, researchers from North Carolina State University have discovered a novel, nontoxic process for producing cellulose gels through freeze-thaw cycles. This breakthrough research opens up new possibilities for creating tunable and sustainable cellulose gels that can revolutionize the field of drug delivery and biomaterials.

Creating hydrogels from cellulose is a complex and delicate process. Traditional methods involve dissolving cellulose and inducing crosslinking to form the desired structure, often requiring the use of toxic solvents or unstable chemicals. Professor Lucian Lucia and his research team at NC State were determined to find a more sustainable and non-toxic approach to develop cellulose hydrogels. By observing the nest-building techniques of swift birds, they came up with an innovative idea to mimic nature’s blueprint.

Swift birds, known for their small size and exceptional nest-building skills, utilize their saliva to interconnect and hold twigs together when constructing their nests. Professor Lucia’s team hypothesized that the saliva acts as a natural resin, encouraging the fibers within the nest to crosslink and form a cohesive structure—an ideal characteristic for creating cellulose hydrogels. Inspired by this natural phenomenon, the researchers embarked on developing a bioinspired process to mimic the behavior of swift birds.

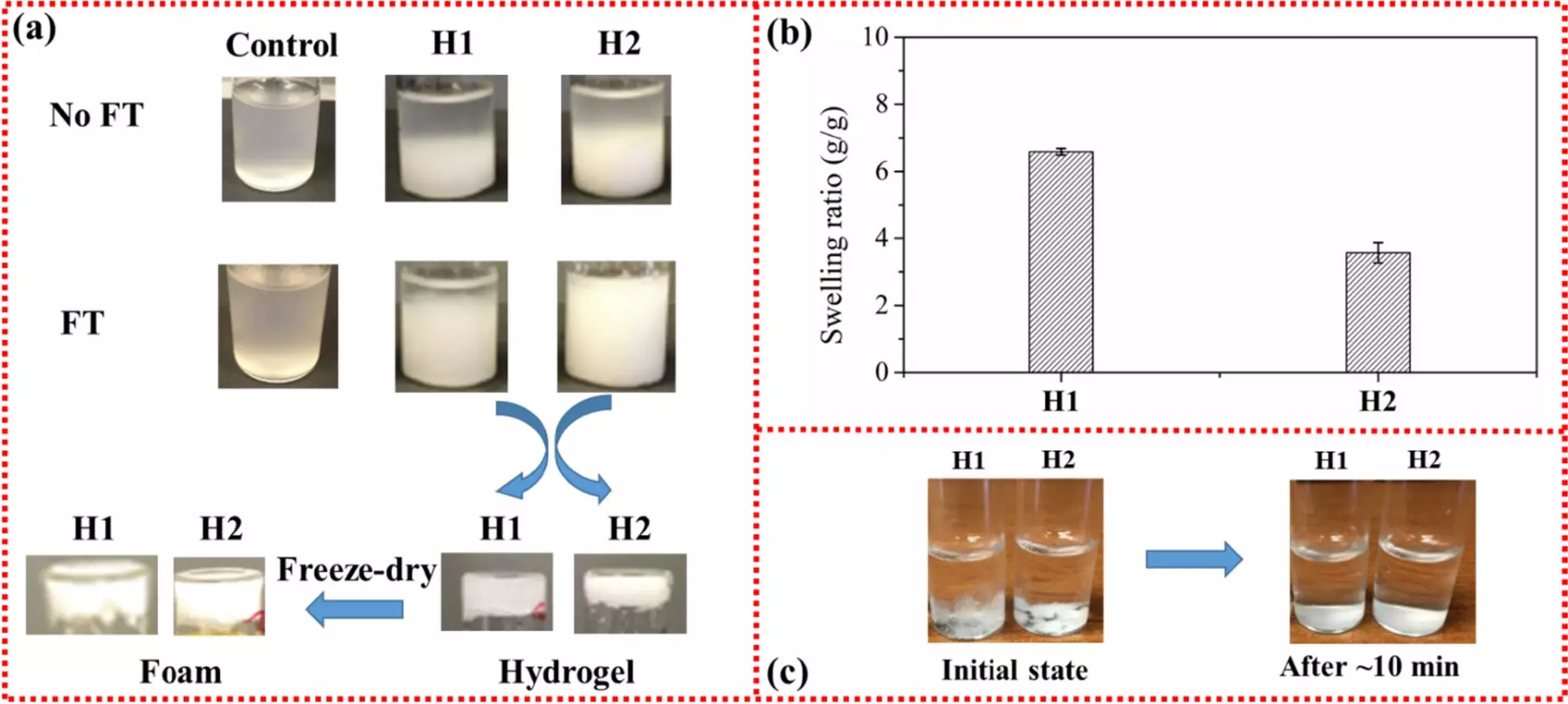

To replicate the swift bird’s nest-making process, the researchers combined a water-soluble cellulose called carboxymethyl cellulose (CMC) with an acid solution, dissolving the CMC. They then introduced powdered cellulose fiber to the solution and subjected it to multiple rounds of freezing and thawing. The outcome was a cellulose gel with a remarkably organized and interconnected structure.

The freeze-thaw process mimics the addition of a thickening agent to water, creating a sticky network. By altering the pH of the CMC solution, the water becomes sticky, enabling the cellulose fibers to compact and interweave, forming a more organized structure—similar to how swift birds’ nests are constructed. The key advantage of this process is that it eliminates the need for beaks and saliva, paving the way for a sustainable and scalable method of producing cellulose gels.

The researchers did not limit their exploration to conventional cellulose sources but also experimented with bamboo fibers. The successful incorporation of bamboo fibers suggests that the freeze-thaw process can be extended to other plant fibers containing lignin and cellulose. This opens up a world of possibilities for transforming various natural resources into functional cellulose gels with wide-ranging applications.

One of the most significant advantages of the developed freeze-thaw process is the production of robust and stable cellulose gels that can be fine-tuned to degrade on a specific schedule. This characteristic makes them highly suitable for applications such as timed drug delivery, where controlled release is essential. Additionally, the cellulose gels remain stable at room temperature, further enhancing their practicality and usability.

The nontoxic freeze-thaw process for creating cellulose gels, inspired by the nest-building techniques of swift birds, represents a significant breakthrough in the field of hydrogel production. By leveraging the natural interconnecting and crosslinking abilities of cellulose fibers, researchers at North Carolina State University have unlocked a sustainable and scalable method for producing cellulose gels. This groundbreaking research paves the way for the development of eco-friendly and non-toxic hydrogels for drug delivery, wound care, and other biomedical applications. By harnessing the power of nature, scientists have taken an important step towards a more sustainable future in biomaterials and pharmaceuticals.

Leave a Reply