Battery safety and performance in electronic devices and systems can be improved thanks to a novel thermal regulator developed at Purdue University’s College of Engineering. The patent-pending, solid-state, continuously tunable thermal devices are based on compressible graphene foam composites. The devices can dissipate heat, insulate against cold, and function across a wide range of temperatures. The researchers believe this technology could be applied to sensors and detectors for scientific or industrial applications that need to be maintained at precise temperatures, as well as electronic devices across a range of applications. The study was published in two peer-reviewed journals: Nature Communications and ACS Applied Materials & Interfaces.

Improving Thermal Management

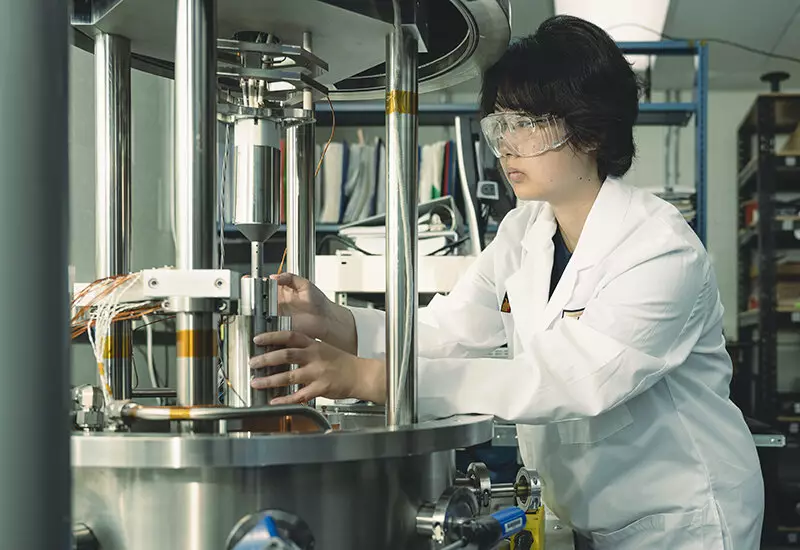

Xiulin Ruan and Amy Marconnet, both professors in the School of Mechanical Engineering at Purdue University, invented the thermal regulator. According to Ruan, “as batteries and electronic devices get more powerful, managing heat becomes a more crucial issue.” As batteries heat up, chemical reactions occur that cause them to heat up even faster. This unstable reaction progression is called ‘thermal runaway’ and can even lead to fires and explosions. On the other hand, if the temperatures are too low, batteries suffer internal damage leading to poor performance like shorter driving ranges for electric vehicles and less cellphone usage time.

Conventional thermal switches tune a battery’s heat dissipation pathways only by changing the conduction between on and off states. The Purdue-invented thermal regulators improve upon this technology by changing the thickness of the material inside the regulators, which helps batteries continually adjust to different climates and seasons.

The commercially available compressible graphene foam Ruan and Marconnet use is built from nanoscopic particles of carbon deposited in a specific pattern with small voids of air in between. When it is uncompressed, the foam acts as an insulator; air pockets keep the heat in place. When it is compressed, air escapes, and heat is conducted throughout. The amount of heat transfer can be precisely dialed in depending on how much the foam is compressed.

Future Developments

Ruan and Marconnet outlined the next steps to further develop the Purdue thermal regulators. They aim to improve the range of thermal conductances achievable with the regulator. The best thermal regulators have a performance ratio of just 10. If they can make the good thermal conductance better and the bad thermal conductance worse, they can make a more effective regulator.

The thermal regulator is manually actuated in the lab. They will work to automate this process, potentially taking feedback from temperature sensors to automatically adjust the parameters.

The thermal regulator developed by Purdue University’s College of Engineering can improve battery safety and performance in electronic devices and systems. The devices can dissipate heat, insulate against cold, and function across a wide range of temperatures. The researchers believe this technology could be applied to sensors and detectors for scientific or industrial applications that need to be maintained at precise temperatures, as well as electronic devices across a range of applications. The next steps for the researchers are to improve the range of thermal conductances achievable with the regulator and automate the process.

Leave a Reply