Robotic systems have already made their way into numerous real-world settings, particularly in the industrial and manufacturing sectors. These systems have proven to be invaluable in assisting human workers in assembly lines and warehouses, where they can perform precise tasks and hand over the completed work to humans for further action. In recent years, researchers and scientists have been increasingly focused on developing advanced systems that can further enhance the collaboration between robots and humans in industrial settings. One proposed solution is the use of “digital twin” systems, which are virtual models that accurately simulate physical objects or components being manufactured.

Researchers at Nanjing University of Aeronautics and Astronautics in China have recently introduced a new digital twin system designed to improve human-robot collaboration in manufacturing settings. The system, as described in their paper published in Robotics and Computer-Integrated Manufacturing, is capable of creating a virtual map of real-world environments and planning suitable robot behaviors to cooperate with humans on specific tasks. The team aims to address the limitations of existing methods that rely on motion capture devices, which require cumbersome equipment and lack a unified space for modeling humans and robots.

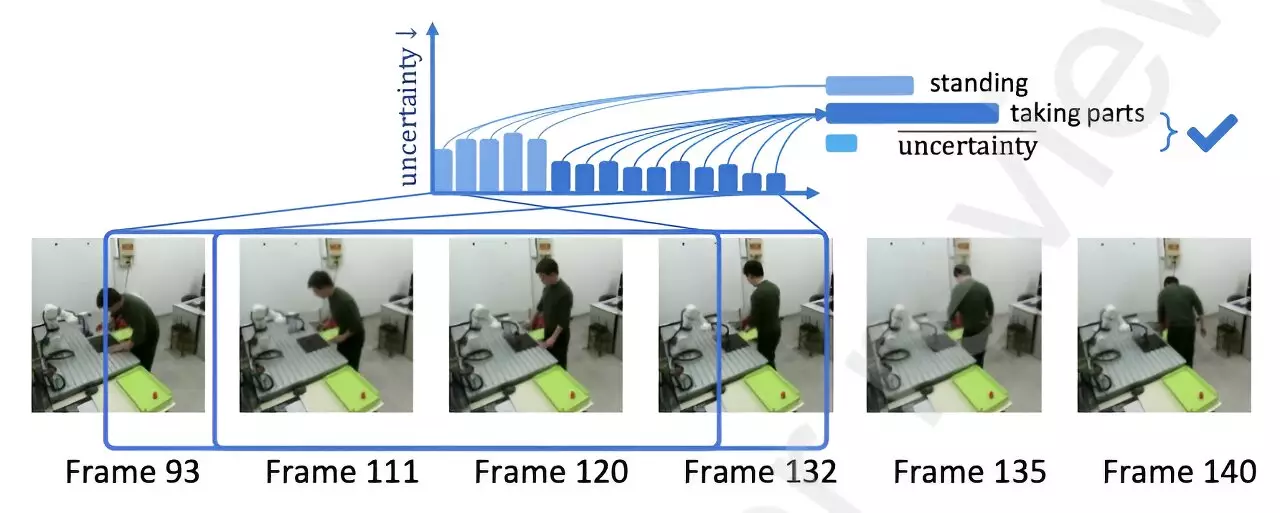

The digital twin system developed by Zhang, Ji, and their colleagues creates a virtual replica of a collaborative scenario between a human and robot agent. This virtual model is then used to plan and execute effective collaborative strategies in the physical environment. To overcome the challenges posed by occlusions, which occur when objects or agents are out of the sensors’ field of view or hidden behind obstacles, the researchers developed a human mesh recovery algorithm. This algorithm aids in reconstructing occluded human bodies, enabling better data collection and analysis. Additionally, they incorporated an uncertainty estimation technique to enhance the performance of the action recognition algorithm, which is trained to identify different human actions. By controlling the algorithm’s error risk, the system becomes more reliable and accurate.

The researchers conducted a series of experiments in laboratory settings using an industrial robot. These experiments aimed to evaluate the effectiveness of their new digital twin system in enhancing collaboration between the robot and a human agent across various tasks, including polishing, picking up, assembling, and placing objects. The results were highly favorable, with the proposed methods outperforming baseline methods. The researchers also conducted a case study involving component assembly to further validate the feasibility and effectiveness of the human-robot collaboration (HRC) system.

The digital twin system developed by Zhang, Ji, and their colleagues holds great promise for industrial robotics. It has the potential to be implemented in other robots used in industrial settings and to undergo further testing and experimentation. Ultimately, this system could find its way into real-world manufacturing environments, significantly enhancing the collaboration between humans and robots in various tasks. The benefits of this enhanced collaboration include increased efficiency, precision, and flexibility in manufacturing processes.

The introduction of the new digital twin system by Zhang, Ji, and their colleagues represents a major step forward in improving human-robot collaboration in manufacturing settings. By overcoming the limitations of existing methods and proposing innovative techniques, the researchers have laid the foundation for more effective and efficient interactions between humans and robots. As the system undergoes further testing and development, it has the potential to revolutionize the manufacturing industry and lead to significant advancements in automation and productivity.

Leave a Reply