Covalent organic frameworks (COFs) have garnered considerable attention in recent years due to their impressive utility in various applications, from gas trapping to environmental remediation. The pressing need for effective solutions to persistent environmental issues has inspired researchers globally to innovate. Among these advances, a team at Rice University, led by chemical engineer Rafael Verduzco, has recently unveiled a groundbreaking method for producing COFs that promises to reshape their usage and application.

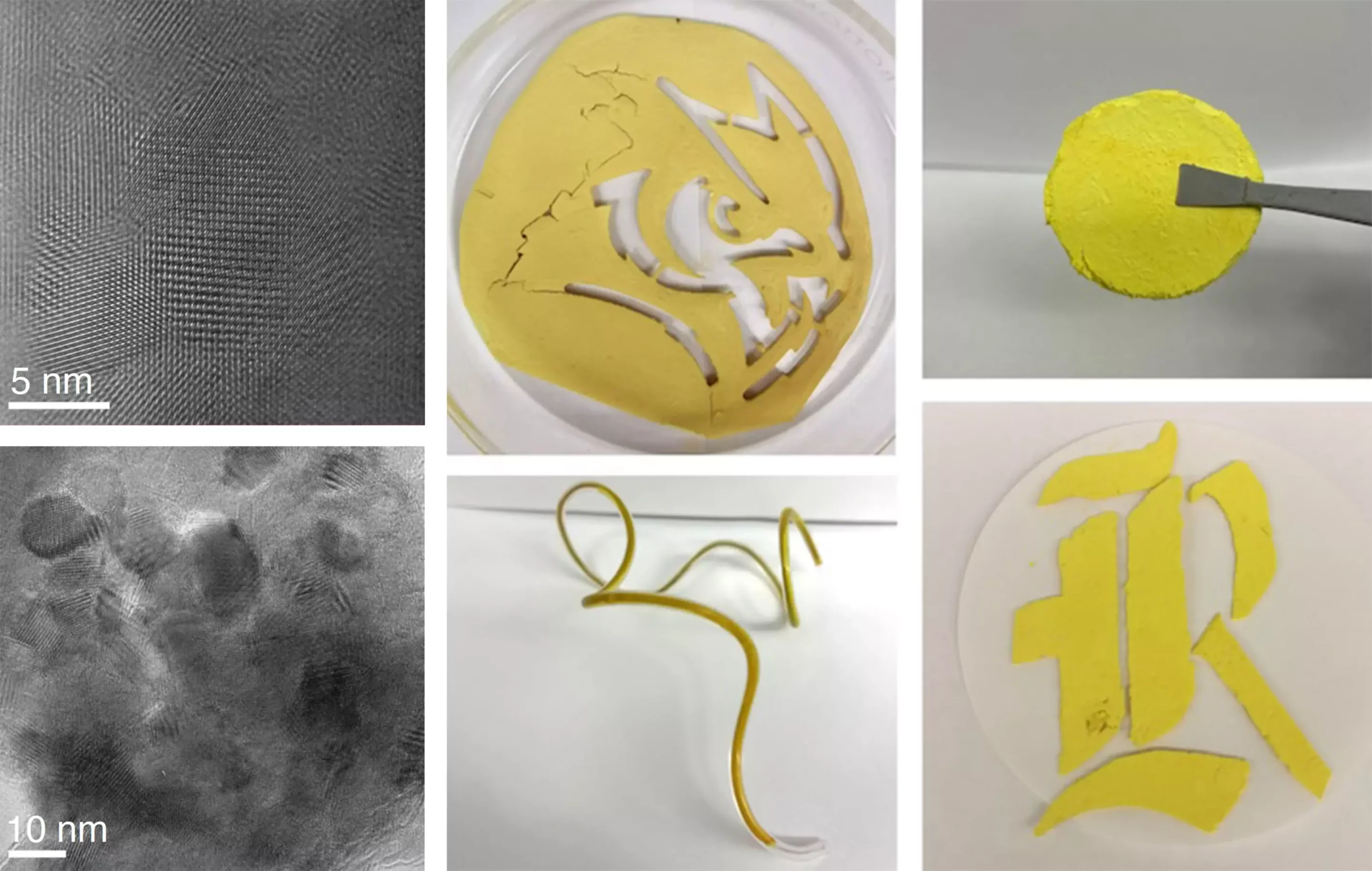

COFs are remarkable materials characterized by their porous, crystalline structures formed by intricate arrangements of small repeating units. Their high surface area and adjustable molecular structures render them suitable for diverse applications, including energy storage, water filtration, and chemical catalysis. A particularly urgent application is their potential in addressing the contamination caused by per- and polyfluoroalkyl substances (PFAS), commonly referred to as “forever chemicals.” These compounds, notorious for their persistence in the environment and their associated health risks, necessitate innovative solutions, making the research led by Verduzco even more imperative.

The hallmark of this recent innovation lies in its production technique. The Rice team developed a continuous flow synthesis method that circumvents many of the limitations associated with traditional COF manufacturing. Conventional methods often involve batch synthesis, which can be labor-intensive, slow, and environmentally taxing due to the need for high temperatures and toxic solvents. In contrast, the new approach employs a multiflow microreactor, which operates more like a “minifactory” on a laboratory bench than a traditional chemical production setup.

Safiya Khalil, the study’s lead author and a Rice doctoral alumna, describes this innovative setup as allowing for a more controlled synthesis environment. Rather than mixing ingredients all at once, the new method enables the ingredients for COFs to be mixed continuously, thereby achieving a more consistent and high-quality product. This attention to detail in regulating the input and output processes means higher throughput and efficiency, significantly lowering production costs.

One of the most significant findings from this research was that one of the COFs produced via the new synthesis method exhibited superior capabilities in breaking down PFOA, a specific type of PFAS. The degradation process, known as photocatalytic degradation, occurs efficiently at room temperature and under the influence of light. Khalil likened these COFs to “powerful sponges with built-in ‘sunlight engines’” that can effectively break down harmful contaminants at an accelerated rate. This realization not only underscores the environmental promise of COFs but also positions them as crucial players in the realm of sustainable chemistry.

What sets this new flow synthesis apart from earlier methods of COF production is its capability to integrate and synthesize multiple chemical frameworks simultaneously. This variability in formulation could pave the way for a broader range of COF applications, catering to specific needs in various industries. Khalil’s analogy of producing cookies to order in small batches effectively encapsulates the essence of this continuous process, which allows for adjustments in temperature and mixing conditions, enhancing the end product’s quality.

While previous approaches to COF synthesis existed, Rice University’s methodology marks a significant improvement by facilitating rapid production without compromising quality. The researchers envision that this method will enable large-scale production, which could accelerate the discovery and deployment of novel COF formulations for more effective environmental and technological applications.

The implications of this research are substantial. As the demand for sustainable materials capable of tackling environmental issues continues to rise, the ability to produce COFs more economically and effectively puts them at the forefront of innovative materials science. With their potential to remove pollutants and serve in various high-tech applications such as sensors and drug delivery systems, this breakthrough has the potential to transform both the field of materials science and practical environmental remediation strategies.

The Rice University team’s innovative synthesis method represents a noteworthy leap forward in the world of covalent organic frameworks. By making COF production more accessible, efficient, and environmentally friendly, this research lays the groundwork for future advancements that may significantly contribute to solving some of our most pressing global challenges, particularly in pollution control and sustainable technology development. As further studies build upon these findings, the future of COFs appears brighter than ever.

Leave a Reply